200W LED driving power supply circuit

A technology of LED drive and power supply circuit, applied in the field of plant lighting, can solve the problems of affecting the service life of LED energy-saving lamps, damage of LED energy-saving lamps, and difficulty in achieving constant current output, etc., to achieve low cost, increase output power, and constant output current Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

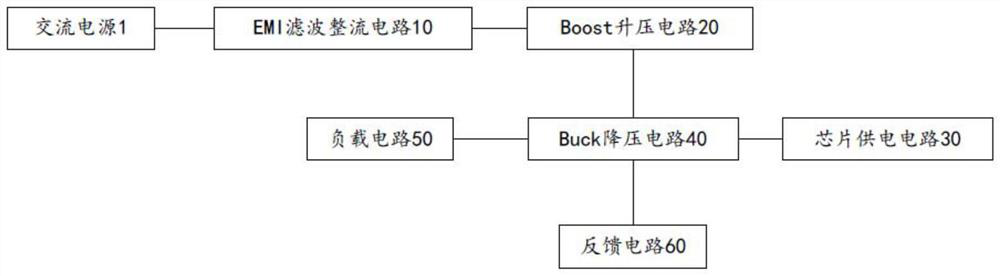

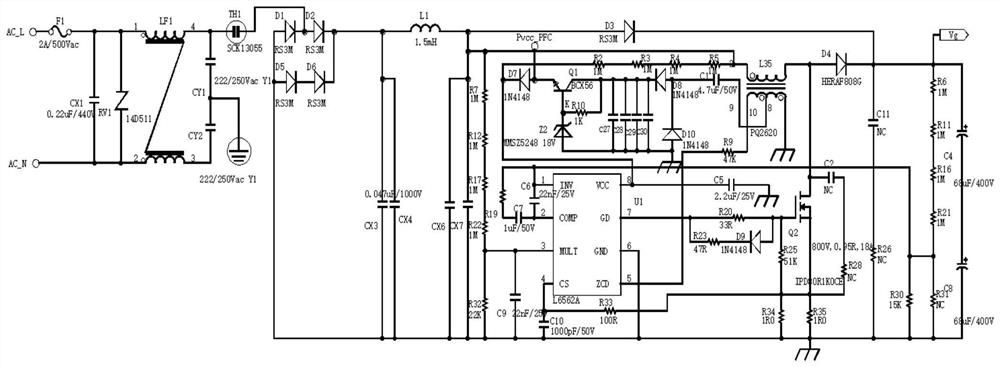

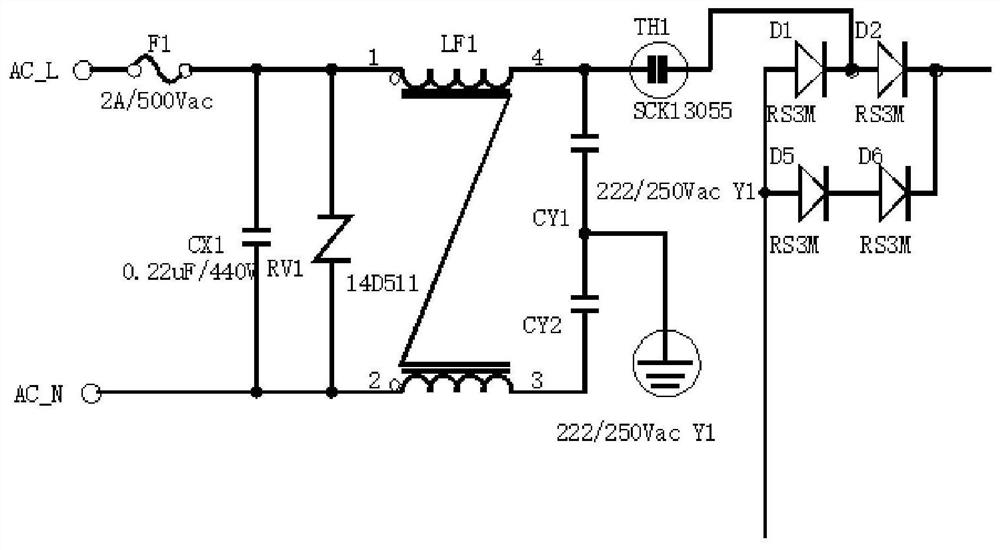

[0031] see figure 1 , a 200W LED drive power circuit of the present invention comprises a strip-shaped PCB substrate packaged with the LED drive power circuit, the LED drive power circuit includes an EMI filter rectifier circuit 10, a Boost voltage boosting circuit 20, and a Buck voltage reduction circuit 40. The load circuit 60, the EMI filter and rectifier circuit 10 is connected to the AC power supply 1, the Boost boost circuit 20 is used to receive the signal rectified by the EMI filter and rectifier circuit 10 and output a DC high voltage signal, and the Buck step-down circuit 40 is used to convert the DC The high voltage signal is stepped down to a constant voltage and output to the load circuit 60 .

[0032] Wherein, a chip power supply circuit 30 is further provided between the Boost voltage boosting circuit 20 and the Buck voltage reducing circuit 40 for providing power to the voltage reducing chip U2 of the Buck voltage reducing circuit 40 . It can be seen that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com