Efficient anti-blocking rotational flow grit chamber device

A technology of cyclone grit chamber and grit chamber, which is used in sedimentation tank, sedimentation separation, chemical instruments and methods, etc., can solve the problems of a lot of manual cleaning, sand pumping, poor sand discharge, etc., and saves money. Human and material resources, avoid poor sand discharge and blockage, and improve the effect of sand extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

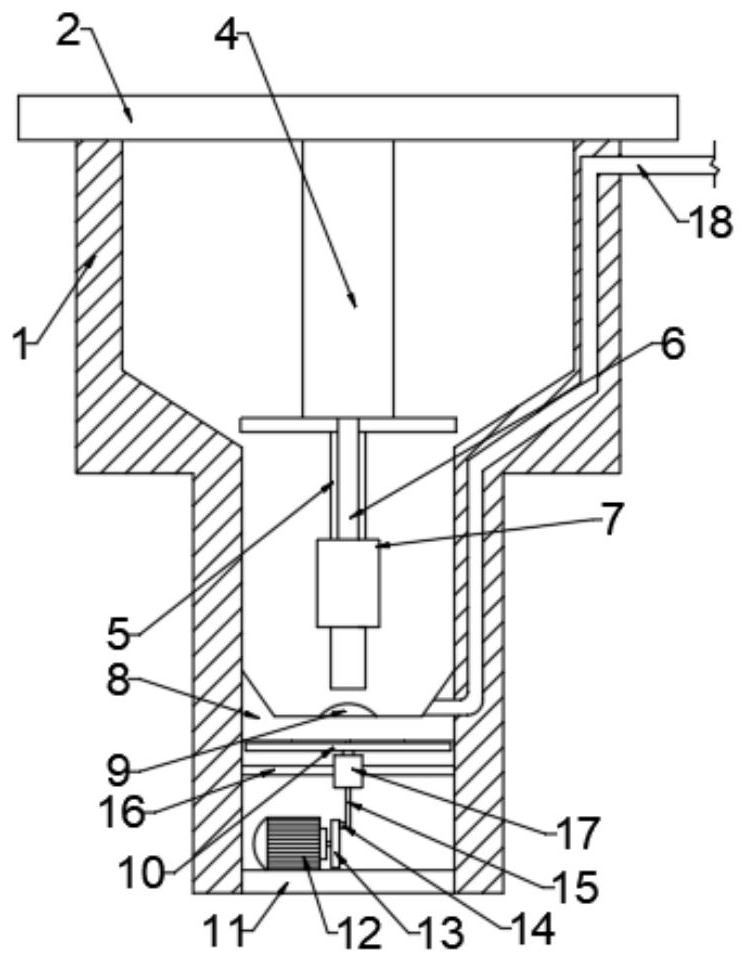

[0038] refer to figure 1 , a high-efficiency anti-blocking swirling flow grit chamber device, including a grit chamber body 1 that is hollow and open at the bottom, a control device 30, a Roots blower 24, a sand-water separator 23, and a multi-stage high-pressure centrifugal pump 19. The top of the pool body 1 is fixedly connected with a cover plate 2, and the top of the cover plate 2 is installed with a driving device 3, and the drive shaft of the driving device 3 runs through the cover plate 2 and is connected with a propeller blade 4;

[0039] The top of the cover plate 2 is fixedly connected with the sand washing pipe 5, the sand lifting pipe 6 and the conveying pipe 22 in sequence. One end of is connected with the input end of sand-water separator 23;

[0040] Electromagnetic valve 20 is installed on the outer wall of sand washing pipe 5 and the outer wall of sand lifting pipe 6, the bottom of sand washing pipe 5, the bottom of sand lifting pipe 6 and the bottom of conveyi...

Embodiment 2

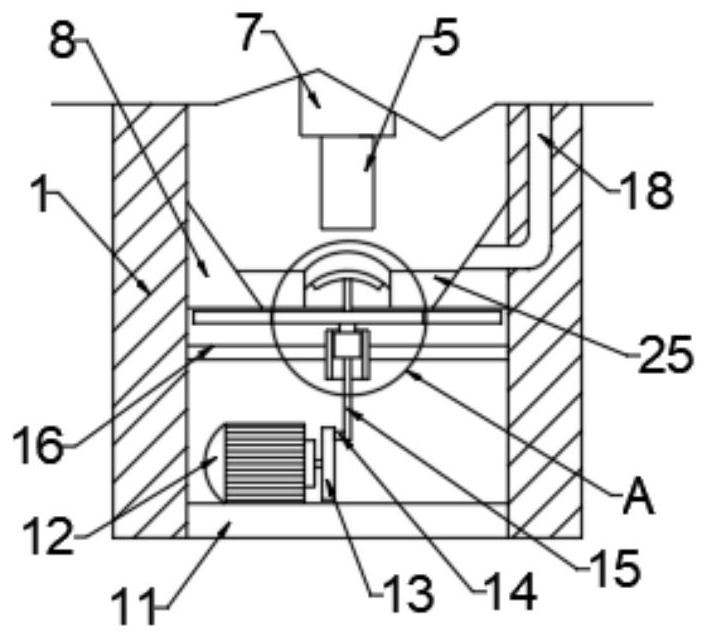

[0049] refer to Figure 2-Figure 8 , a high-efficiency anti-blocking swirling flow grit chamber device, including a grit chamber body 1 that is hollow and open at the bottom, a control device 30, a Roots blower 24, a sand-water separator 23, and a multi-stage high-pressure centrifugal pump 19. The top of the pool body 1 is fixedly connected with a cover plate 2, and the top of the cover plate 2 is installed with a driving device 3, and the drive shaft of the driving device 3 runs through the cover plate 2 and is connected with a propeller blade 4;

[0050] The top of the cover plate 2 is fixedly connected with the sand washing pipe 5, the sand lifting pipe 6 and the conveying pipe 22 in sequence. One end of is connected with the input end of sand-water separator 23;

[0051] Electromagnetic valve 20 is installed on the outer wall of sand washing pipe 5 and the outer wall of sand lifting pipe 6, the bottom of sand washing pipe 5, the bottom of sand lifting pipe 6 and the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com