Bridge construction spraying device convenient to use and adjustable in spraying area

A technology of bridge construction and spraying equipment, applied in the direction of spraying equipment, etc., can solve the problems of inconvenient use, spraying waste efficiency, etc., and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

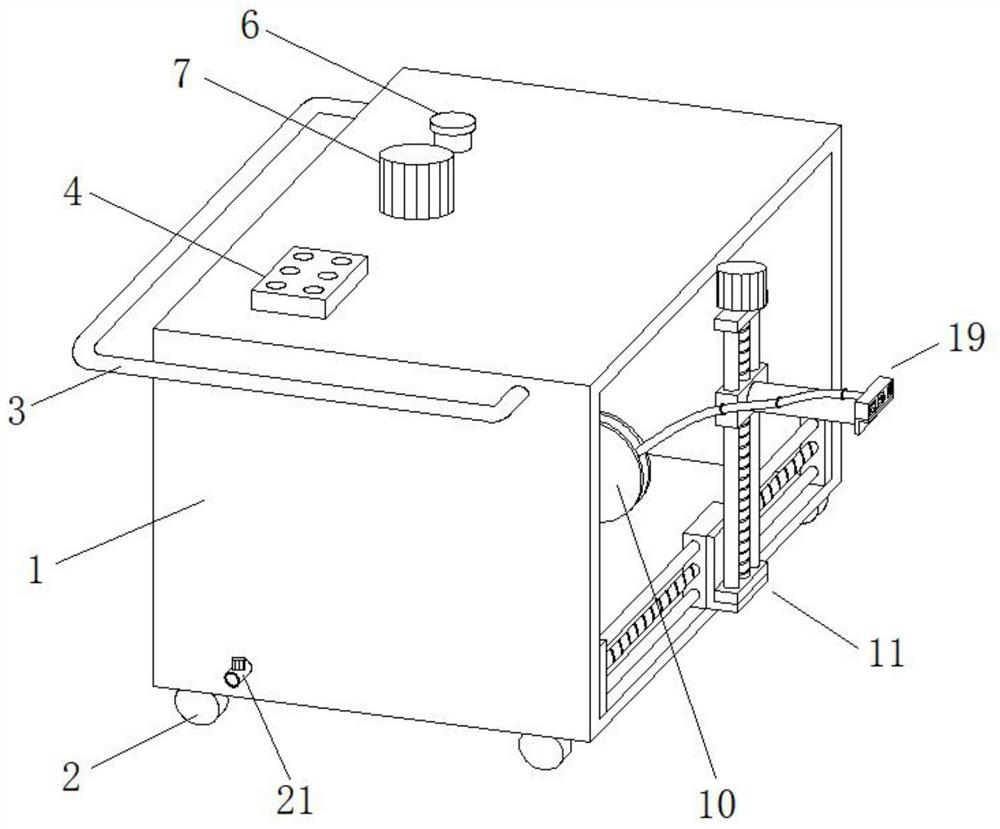

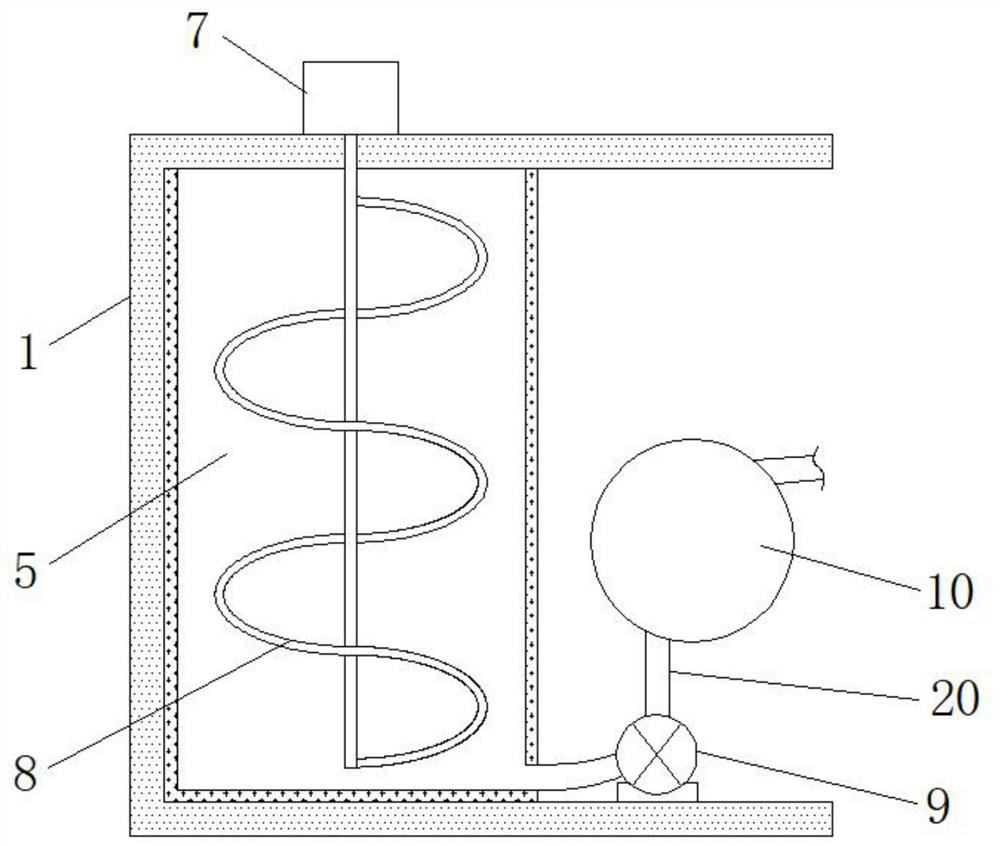

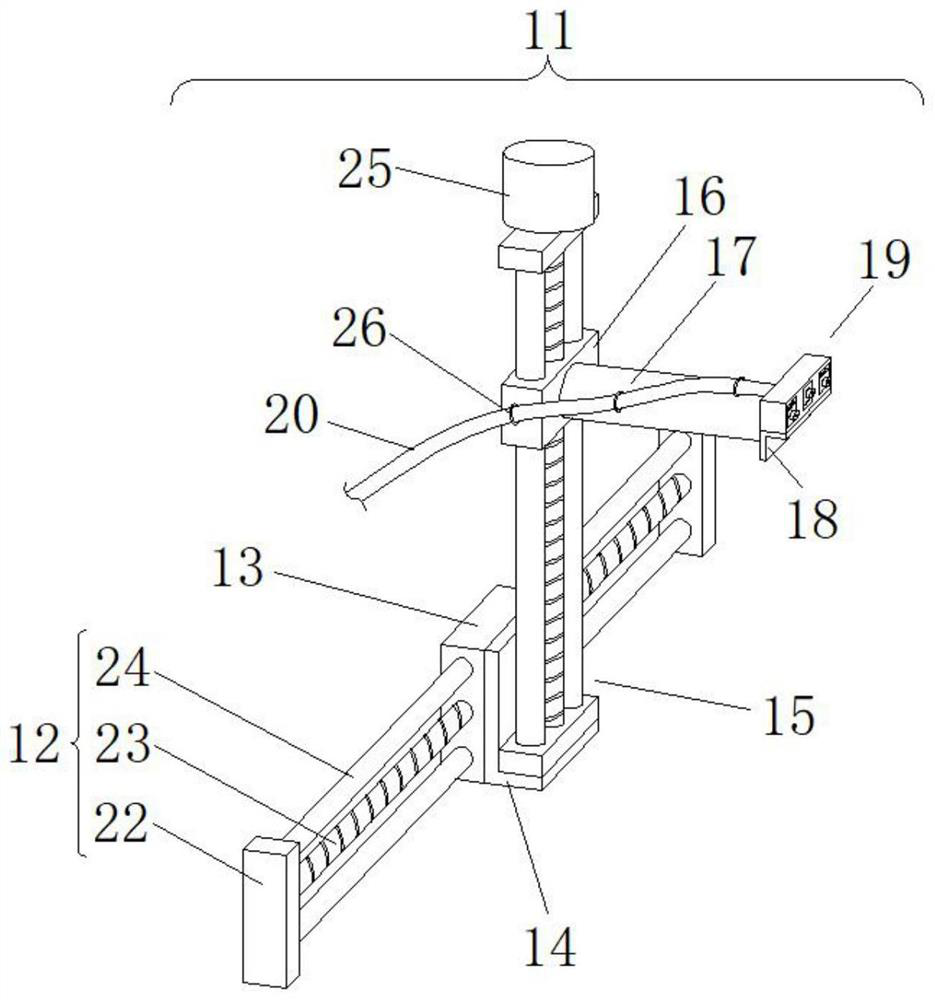

[0031] see Figure 1-2 , a spraying device for bridge construction that is convenient to use and has an adjustable spraying area, comprising an outer box body 1, universal wheels 2 are fixedly installed at the four corners of the bottom of the outer box body 1, and the outer side of the outer box body 1 An L-shaped handle 3 is fixedly installed on the top, a control switch 4 is fixedly installed on one end of the top of the outer box body 1, and a material barrel 5 is arranged at an inner end of the outer box body 1, and a feeding port is opened above the material barrel 5 6. A stirring motor 7 mounted on the outer box 1 is arranged above the material barrel 5, and the output shaft of the stirring motor 7 is equipped with a stirring rod 8 extending into the inside of the material barrel 5. The outer box 1 The other end of the interior is equipped with a water pump 9 and a spring reel 10, and one end of the outer box 1 is fixedly equipped with a biaxial movement mechanism 11, a...

Embodiment example 2

[0036] see Figure 4-6 , the adjustable spray head mechanism 19 includes a diverter valve body 27 fixedly installed on the second L-shaped mounting plate 18, the inside of the diverter valve body 27 is provided with a split-three pipeline 28, and the outside of the diverter valve body 27 Three chutes 40 in the vertical direction are evenly arranged, and the inside of the chute 40 is slidably installed with a nozzle mounting seat 29, and the upper and lower ends of the nozzle mounting seat 29 are provided with plug joints 30, and the nozzle mounting seat 29 29 are provided with through holes 31 inside, and the outside of the nozzle mount 29 is fixed with a nozzle 32; when the nozzle mount 29 slides to the top of the chute 40 in the chute 40, the nozzle mount The through hole 31 provided in 29 communicates with the branch part of the one-point-three pipeline 28 inside the diverter valve body 27, and rubber sealing gaskets are installed at the sliding connection between the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com