Communication device insulation processing system

A technology for insulation treatment and communication devices, which is applied in coatings, devices for coating liquid on the surface, etc., and can solve problems such as the inability to adhere to electronic components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

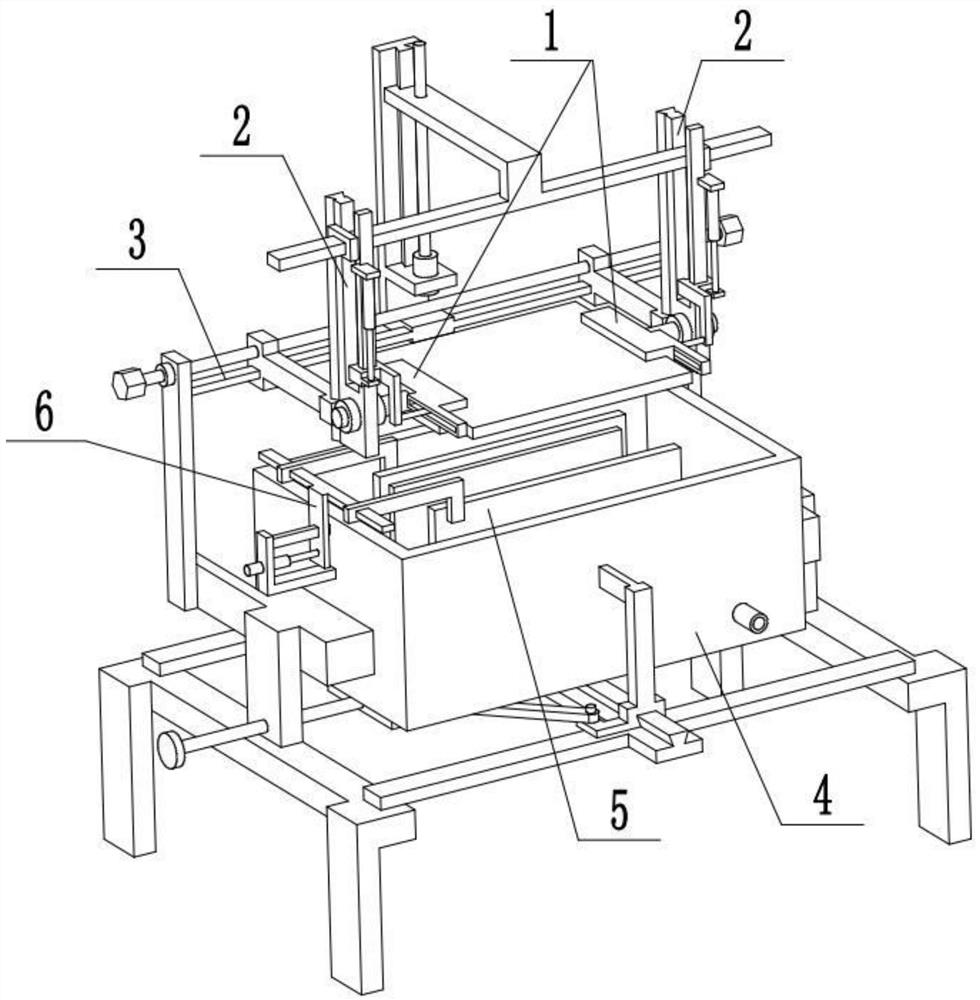

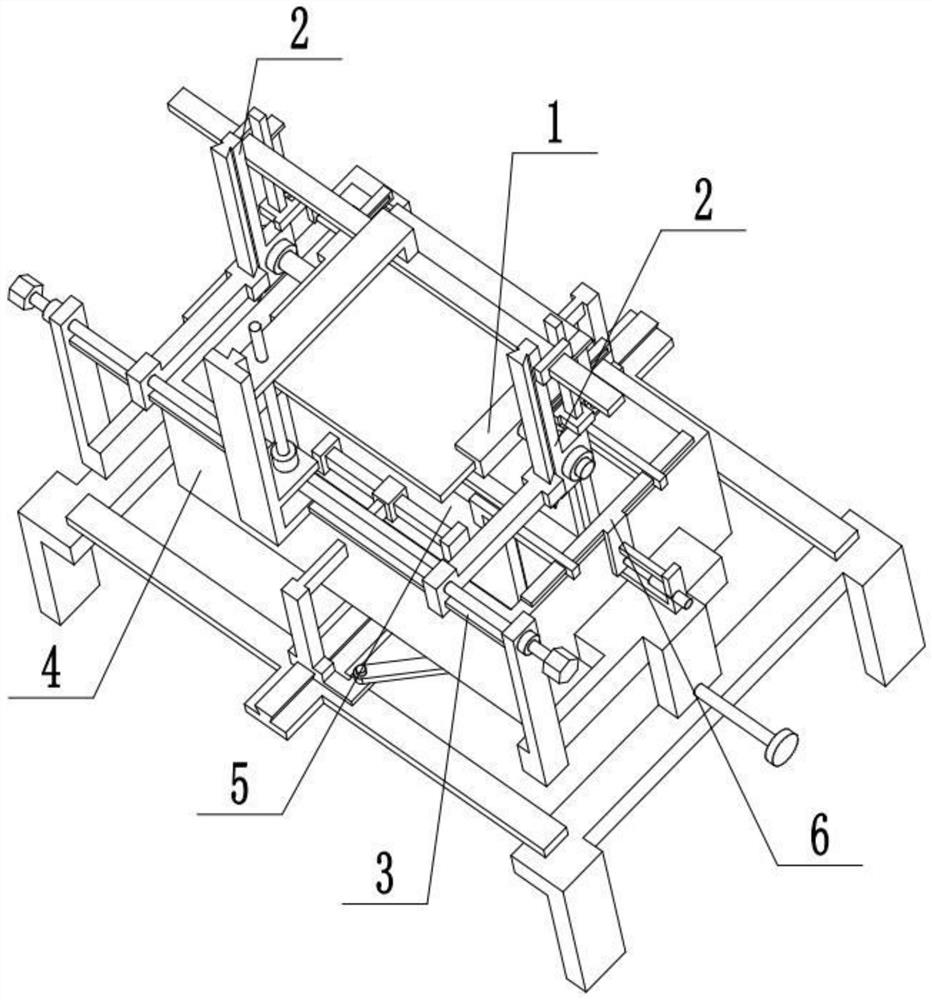

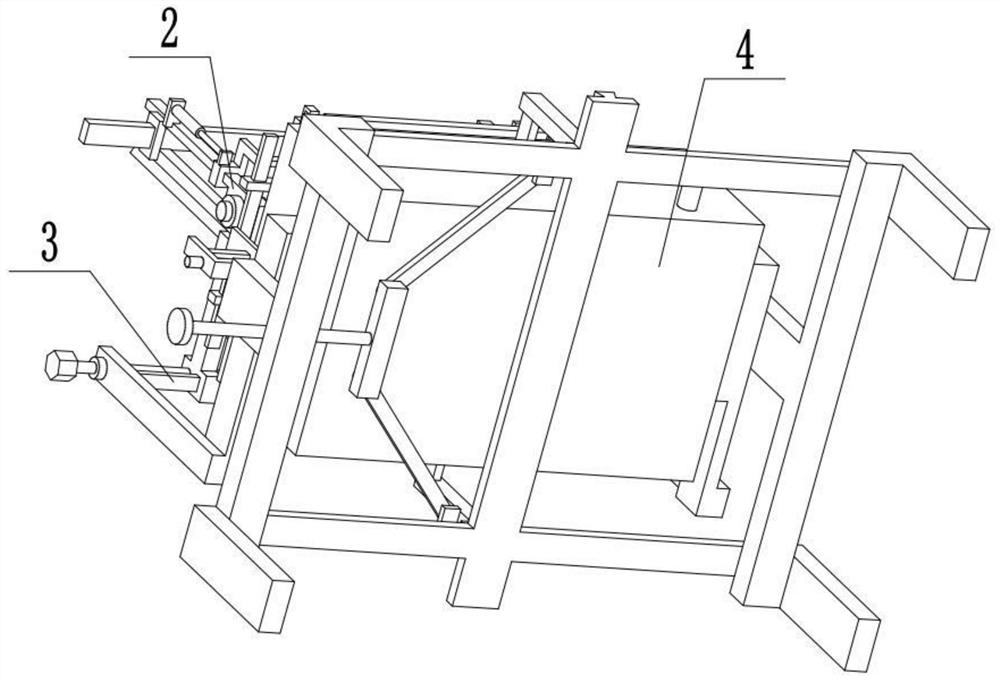

[0025] Combine below Figure 1-7 Describe this embodiment, an insulation treatment system for communication devices, including a chassis 3-8, an oil tank 4, a brush plate 5, an L-shaped rod 5-1, a trapezoidal edge 5-2, an I-shaped frame 5-3, and an articulated arm 5-4, the square plate 5-5 and the externally threaded rod 5-6, the fuel tank 4 is fixedly connected between the two underframes 3-8, and the two L-shaped rods 5-1 are symmetrically slidably connected to the bottom of the fuel tank 4 At the front and rear ends, the inner ends of the two L-shaped rods 5-1 are respectively provided with a brush plate 5, and the outer ends of the two L-shaped rods 5-1 are respectively slidably connected to the two ends of the trapezoidal rib 3 5-2, and the trapezoidal rib Three 5-2 are fixedly connected to the middle part of the I-shaped frame 5-3, the I-shaped frame 5-3 is fixedly connected on the two underframes 3-8, and the external threaded rod 5-6 is threadedly connected to the left...

specific Embodiment approach 2

[0027] Combine below Figure 1-7 To illustrate this embodiment, the communication device insulation treatment system further includes a square rod 5-7, an ear plate 5-8, a lower T-shaped plate 6, an insertion rod 6-1, an L-shaped plate 6-2 and a cylinder two 6-3, the outer end surfaces of the two brush plates 5 are respectively fixedly connected with a square rod 5-7, and the inner ends of the two L-shaped rods 5-1 are respectively movably connected with a square rod 5-7; the L-shaped board 6- 2 is fixedly connected to the left end of the fuel tank 4, the plunger 6-1 and the second oil cylinder 6-3 are fixedly connected to the L-shaped plate 6-2, and the telescopic end of the second oil cylinder 6-3 is fixedly connected to the lower end of the lower T-shaped plate 6, The lower T-shaped plate 6 is slidably connected to the insertion rod 6-1, and the two ends of the lower T-shaped plate 6 are respectively movably connected to an ear plate 5-8, and the two ear plates 5-8 are resp...

specific Embodiment approach 3

[0029] Combine below Figure 1-7To illustrate this embodiment, the communication device insulation treatment system further includes a U-shaped splint 1, an upper T-shaped plate 1-1, a guide rod 3, a shaft frame 3-1, a rear frame plate 3-2, and a trapezoidal edge 2 3-3. Motor 3-4 and lead screw 3-5; two base frames 3-8 are respectively fixedly connected with a shaft frame 3-1, and the guide rod 3 is fixedly connected between the two shaft frames 3-1, and the rear frame The plate 3-2 is fixedly connected to the middle part of the guide rod 3, the trapezoidal edge 2 3-3 and the motor 3-4 are all fixedly connected to the rear frame plate 3-2, and the output shaft of the motor 3-4 is fixedly connected to the lead screw 3-5, The upper T-shaped plate 1-1 is slidingly connected on the trapezoidal edge 2 3-3, the upper T-shaped plate 1-1 is threadedly connected with the lead screw 3-5, and a U-shaped splint 1 is respectively provided at both ends of the lead screw 3-5 . Insert the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com