Feed shaft diagnostic device and feed shaft diagnostic method for machine tool

A diagnostic device and feed shaft technology, which is applied in the direction of metal processing machinery parts, machine gear/transmission mechanism testing, metal processing equipment, etc., can solve the problems of sensor interference, increased sensor cost, increased failure risk, etc., and achieve high precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be described below with reference to the drawings.

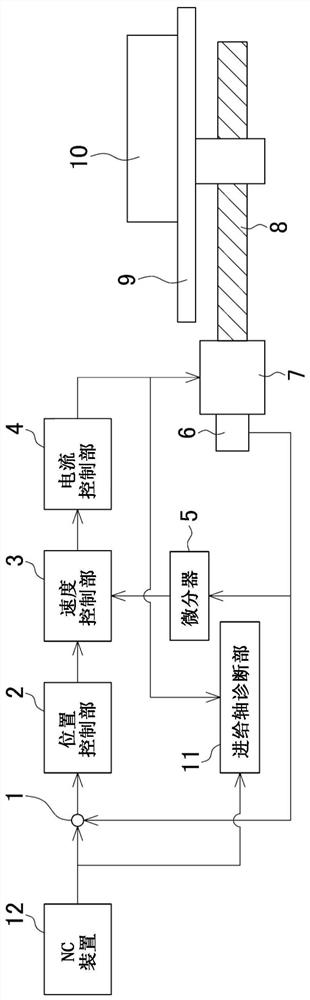

[0026] figure 1 It is an explanatory diagram showing the diagnosis device of the feed shaft according to the present invention.

[0027] In this machine tool, a moving body 9 is provided so as to be slidable by a ball screw 8 which is driven to rotate by a servo motor 7 . The moving body 9 can move linearly along the guide surface of the rolling guide mechanism 10 .

[0028] In machining of a workpiece not shown, the servomotor 7 drives the movable body 9 via the ball screw 8 to move the workpiece placed on the movable body 9 to a predetermined position, thereby performing machining.

[0029] The feed axis diagnosis device includes: a position detector 6, which is provided on the servo motor 7, and detects the position of the moving body 9 by detecting the rotational position of the servo motor 7; an NC device 12, which outputs a position command value of the moving body 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com