Turbine flange butterfly valve

A flange and butterfly valve technology, which is applied in the field of butterfly valve installation, can solve the problems of low adaptability of the clamping mechanism to the size of the valve body, easy deviation of the valve body from the vertical direction, and low stability of the valve body, so as to expand the applicable scope of clamping , avoid the effect of decreasing the sealing degree and improving the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

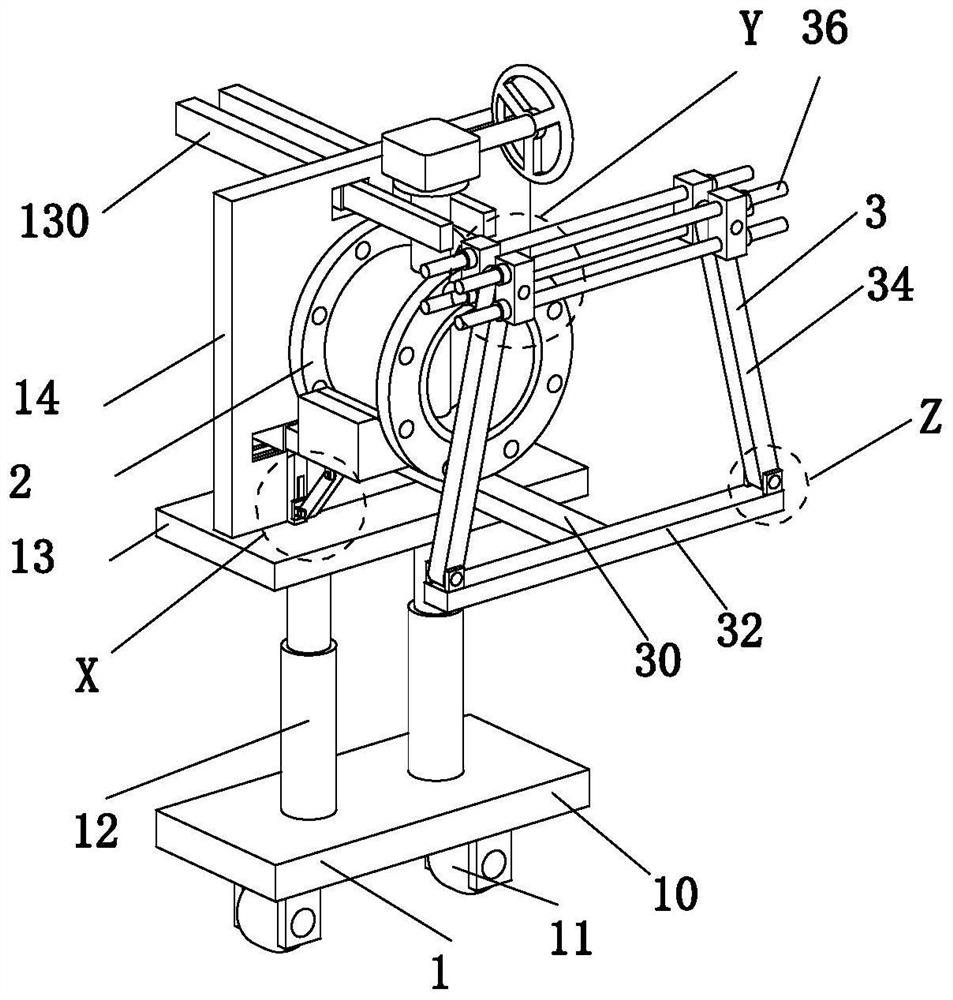

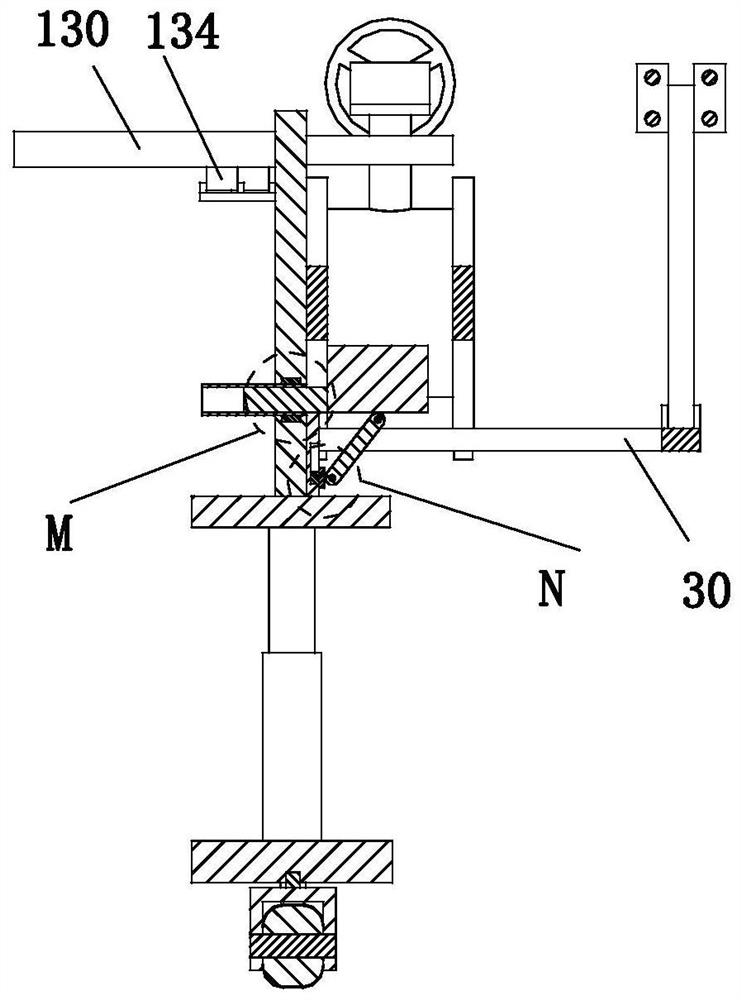

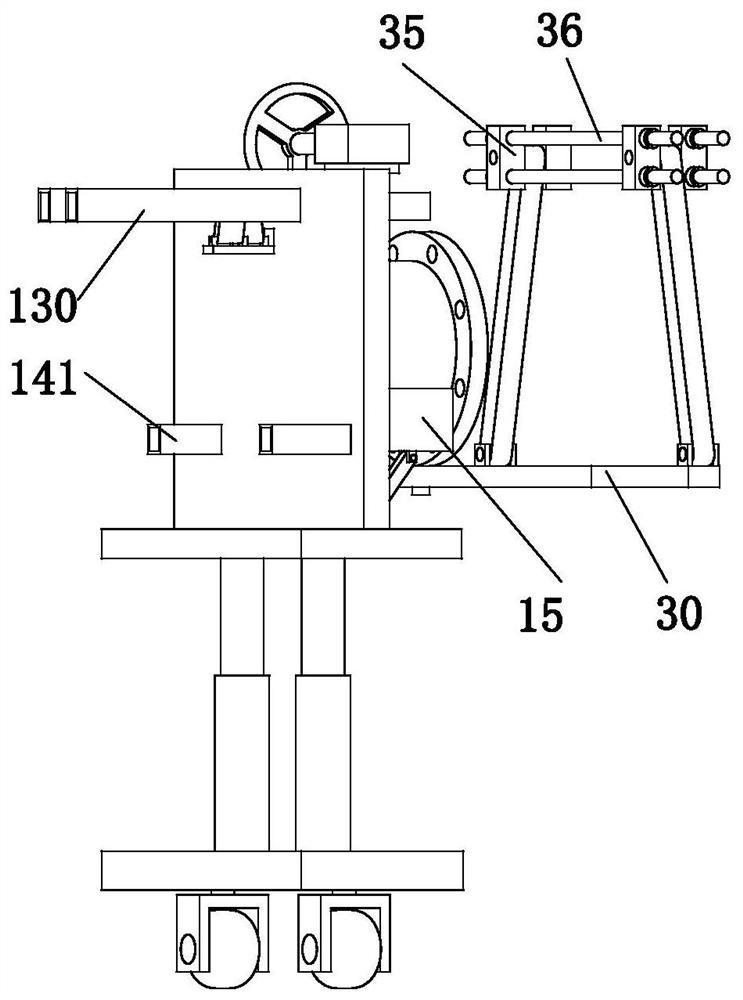

[0033] like Figure 1 to Figure 11 As shown, a turbine flange butterfly valve includes a main solid mechanism 1, a valve body 2 and an auxiliary solid mechanism 3. The lower end of the main solid mechanism 1 is connected to the existing ground by a sliding fit. The main solid mechanism 1 The upper end of the valve body 2 is connected with the valve body 2, and the front end of the valve body 2 is provided with an auxiliary fixing mechanism 3.

[0034]The main solid mechanism 1 includes a base plate 10, a universal wheel 11, an electric push rod 12, a base plate 13, a riser 14 and a support block 15, the lower end of the base plate 10 is symmetrically equipped with a universal wheel 11, and the upper end surface of the base plate 10 Electric push...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com