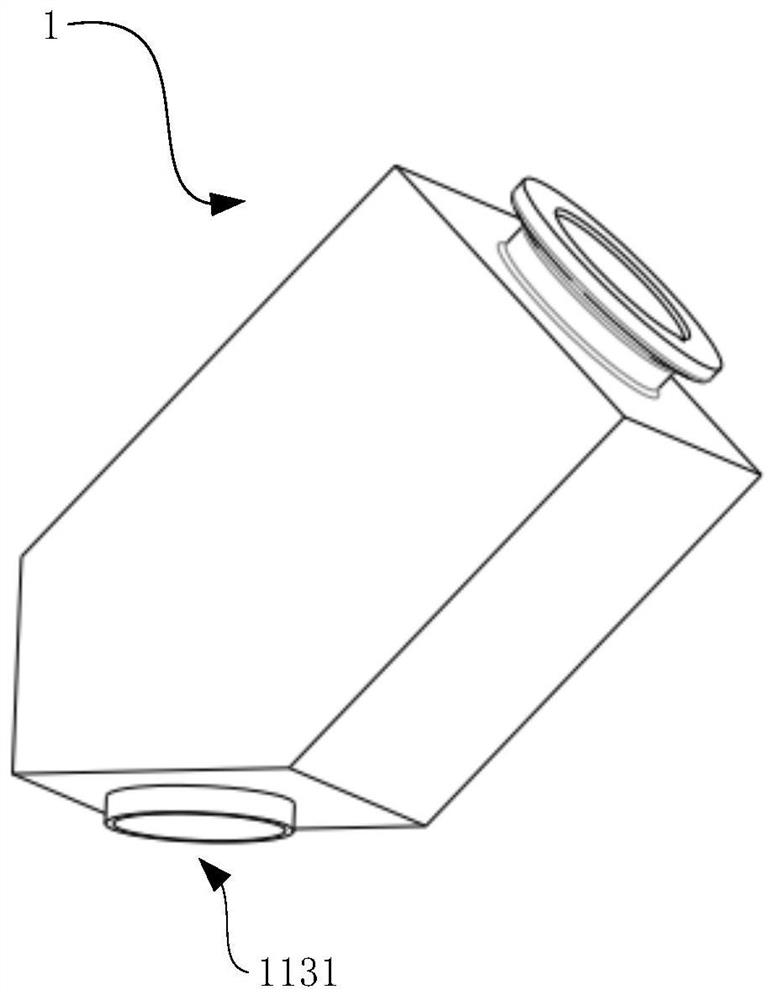

Throttling system, filling machine and cleaning method

A technology of throttling area and throttling components, which is applied in the direction of filling device cleaning, packaging, bottle filling, etc., can solve the problems of difficult flushing liquid, poor surface cleanliness of seals, etc., to reduce liquid residue and improve safety , Improve the effect of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

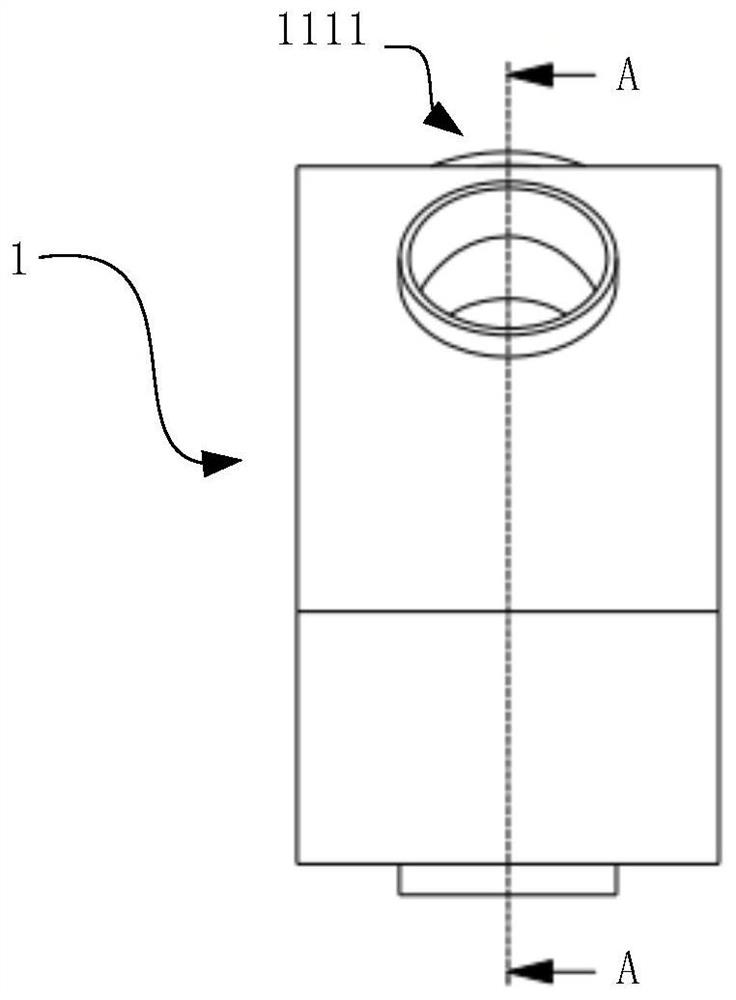

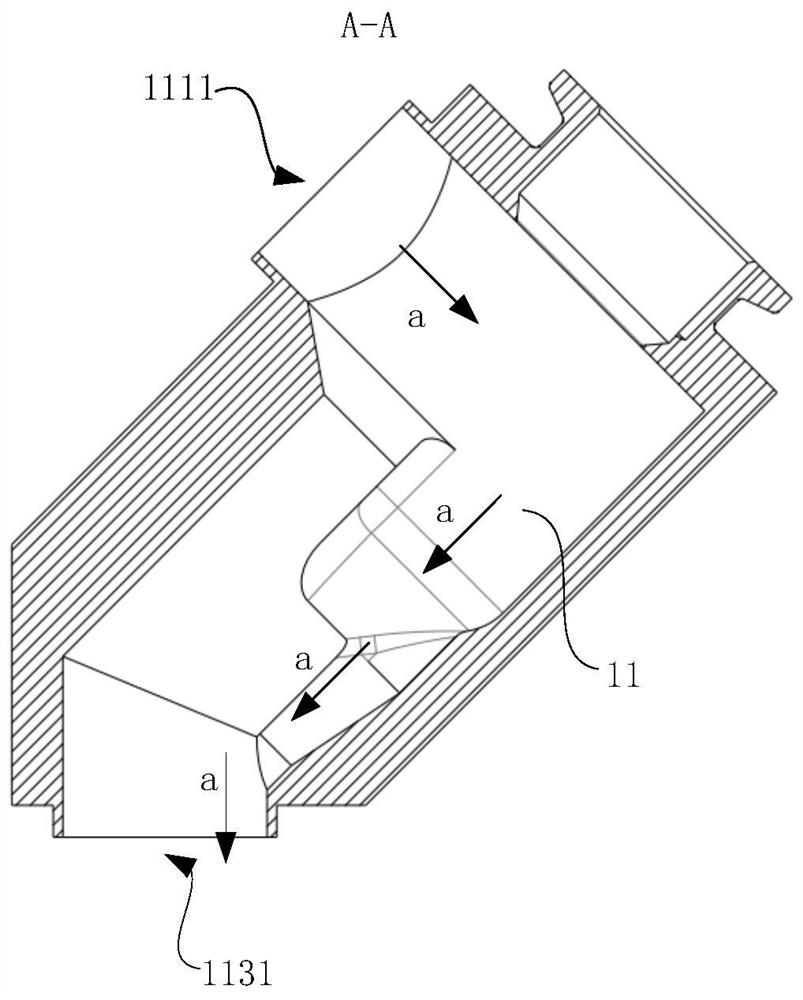

[0057] An optional implementation manner: the throttling area of the upper opening is larger than the throttling area of the lower opening.

[0058] When the driving assembly 22 drives the connecting rod 212 to move, the connecting rod 212 drives the valve core 211 to move along the extending direction of the connecting rod 212 . Specifically, when the connecting rod 212 moves to the maximum stroke, the size of the regulating port is the smallest and the throttle area is the smallest; when the connecting rod 212 moves to the minimum stroke, the size of the regulating port is the largest and the throttle area is the largest.

[0059] It should be noted that, when cleaning the throttling system provided by the embodiment of the present invention along the direction a, the connecting rod 212 can be driven to the minimum stroke position through the driving assembly 22, so that the flushing fluid can fully flush the valve sleeved outside the connecting rod 212. The seal prevent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com