Fabrication method and fabric of silk outlet hole, integrated fiber of optoelectronic chip

A technology for optoelectronic chips and manufacturing methods, applied in fabrics, braids, fiber processing, etc., can solve the problems of limited fiber length, complex preparation process, complex fiber devices, etc., and achieve excellent performance, high luminous intensity, and low power consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

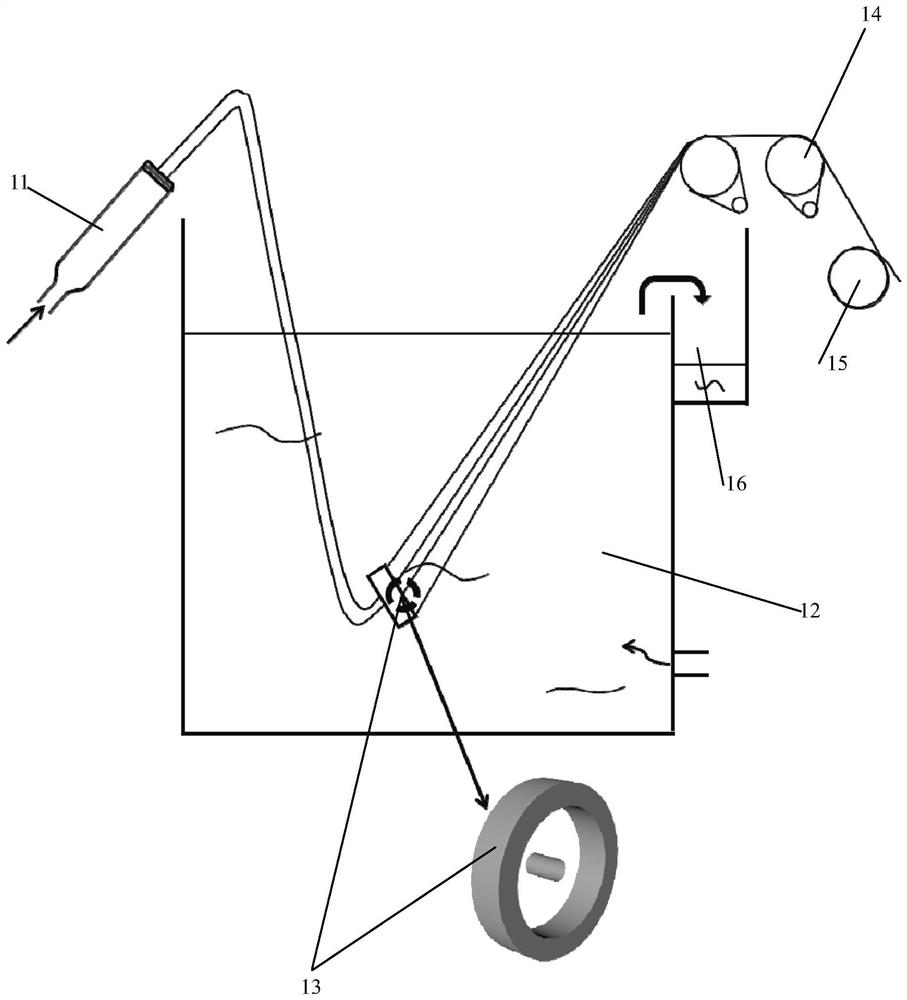

[0092] In the first embodiment of the present invention, a red light emitting fiber is prepared by a wet spinning method.

[0093] The fibrous base material selects PC particles with a diameter of about 3 mm. The optoelectronic chip selects a light-emitting diode, specifically, an AlGaInP red light-emitting diode from ES-SABRPN14D of EPISTAR Company in Taiwan, China, with a wavelength of 660 nm, a chip size of 340 μm × 340 μm × 170 μm, and electrical contacts on opposite sides of the chip. The lead wire is a tungsten wire with a wire diameter of 50 μm.

[0094] Preparation of spinning substrate: 40 g of PC particles were dried in a vacuum oven at 60 °C for 24 hours, taken out, and then added with 350 mL of dimethylformamide solvent, and stirred in the dark until the particles were completely dissolved, to obtain a certain viscosity and good reproducibility. Spinnable spinning substrate.

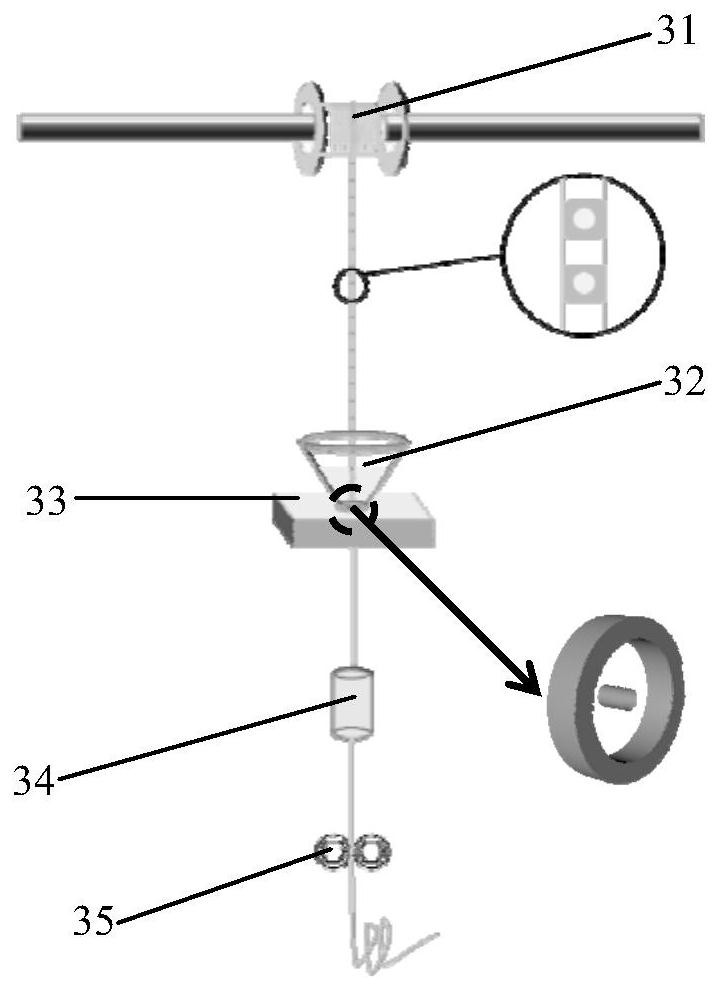

[0095] Arrange a plurality of red light-emitting diodes at intervals along one directio...

Embodiment 2

[0098] In the second embodiment of the present invention, the red light emitting hydrogel fiber is prepared by wet spinning method.

[0099] The fibrous base material selects sodium alginate particles with a diameter of 2 mm. The light-emitting diode is an AlGaInP red light-emitting diode of ES-SABRPN14D from EPISTAR, China, with a wavelength of 660 nm, a chip area of 340 μm × 340 μm × 170 μm, and electrical contacts on opposite sides of the chip. The lead wire is a tungsten wire with a wire diameter of 50 μm.

[0100] Preparation of spinning substrate: drying 35 g of sodium alginate particles in a vacuum oven at 60°C for 24 hours, taking out and adding 300 mL of cold water, stirring until the particles are completely dissolved, to obtain a spinning substrate with a certain viscosity and good spinnability .

[0101] Arrange a plurality of red light-emitting diodes at intervals along one direction, in a row, use a wire bonding machine, and follow the Figure 4 In the metho...

Embodiment 3

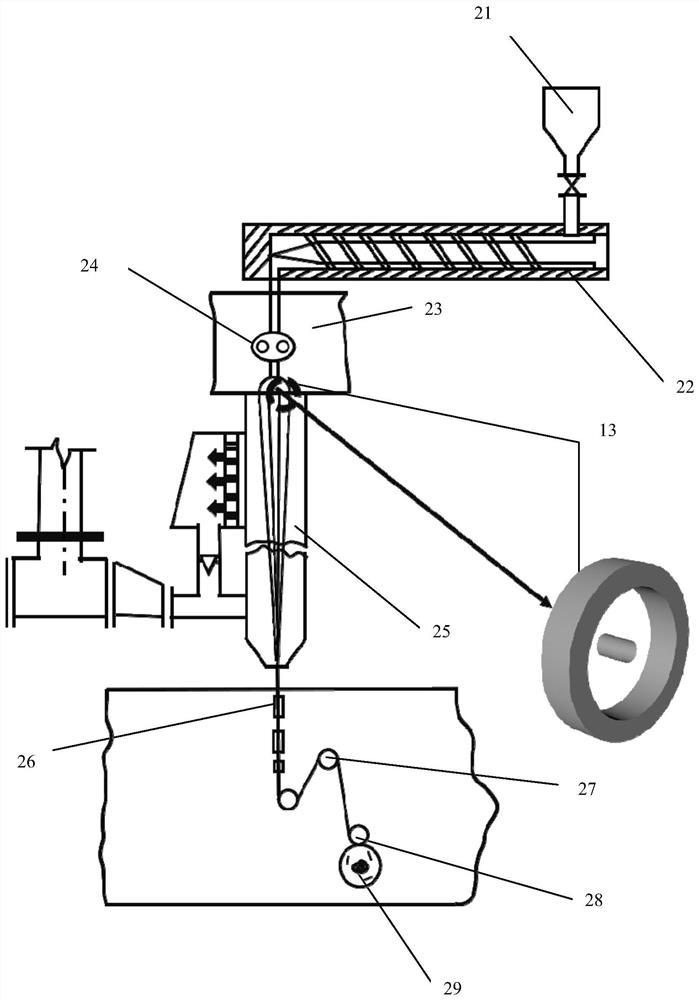

[0104]In the third embodiment of the present invention, a red light emitting fiber is prepared by a melt spinning method.

[0105] The fibrous base material selects PC particles with a diameter of about 3 mm. The optoelectronic chip selects light-emitting diodes, specifically the AlGaInP red light-emitting diodes from ES-SABRPN14D of EPISTAR Company in Taiwan, China, with a wavelength of 660nm, a chip area of 340μm × 340μm × 170μm, and electrical contacts on opposite sides of the chip. The lead wire is a tungsten wire with a wire diameter of 50 μm.

[0106] Arrange a plurality of red light-emitting diodes at intervals along one direction, in a row, use a wire bonding machine, according to Figure 4 In the method of , two tungsten wires with a wire diameter of 50 μm are welded to the two pins of the red light-emitting diode respectively to form a combination of photoelectric chips and leads. Each of the red light emitting diodes is separated by 30mm, and a row of 500 red li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com