Spherical support with additional anti-drawing function

A ball bearing and anti-pulling technology, applied in bridge parts, bridges, buildings, etc., can solve the problems of difficult assembly, complex structure, easy loosening, etc., to increase the difficulty of processing, simplify the installation process, and increase the difficulty of assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

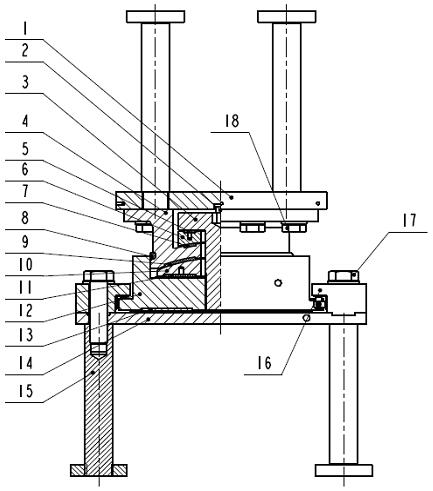

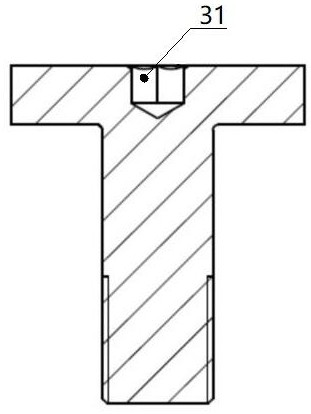

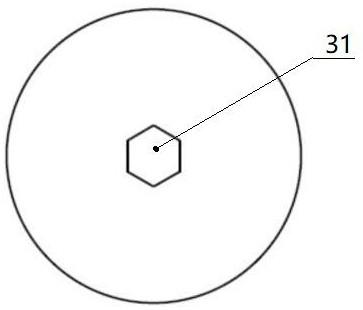

[0039] Provide a spherical bearing with additional anti-drawing function, the bearing includes an upper bearing plate 1, a sliding plate 14, a piston 4 and a lower bearing plate 12 that cooperate with each other; the two ends of the piston 4 are respectively opened with A concave spherical surface and a convex spherical surface, a middle seat plate 10 is placed in the concave spherical surface, and a middle seat plate 1 6 is placed on the convex spherical surface; the middle seat plate 10 is located between the piston 4 and the lower support Between the boards 12; the second middle seat board 10 and the first middle seat board 6 are spherical surfaces with the same arc direction.

[0040] Also includes anti-pullout bolts 3, such as figure 1 As shown, the screw rod of the bolt 3 passes through the middle seat plate one 6, the piston 4, the middle seat plate two 10, the lower support plate 12 and the sliding plate 14 to fix in turn, and the middle seat plate one 6 is located at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com