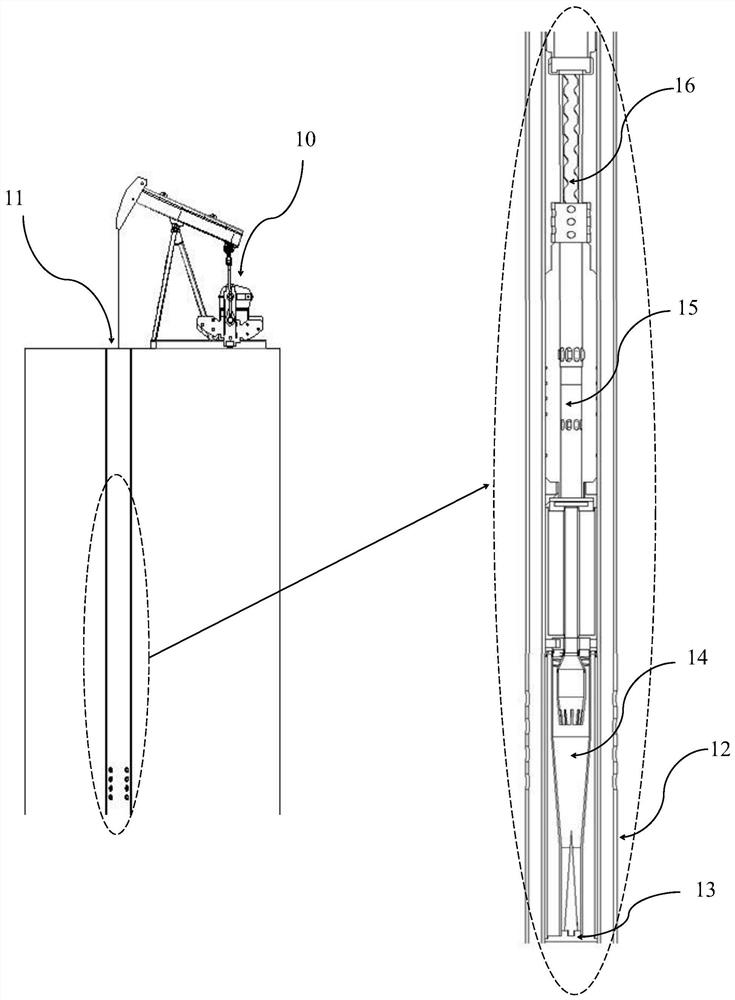

A downhole gas-liquid separation device suitable for shale oil pumping unit oil production system

A technology of oil production system and pumping unit, which is applied in the direction of production fluid, earthwork drilling and production, wellbore/well parts, etc., which can solve the problems of increased demand, achieve the effects of reducing impact, avoiding efficiency reduction, and reducing occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

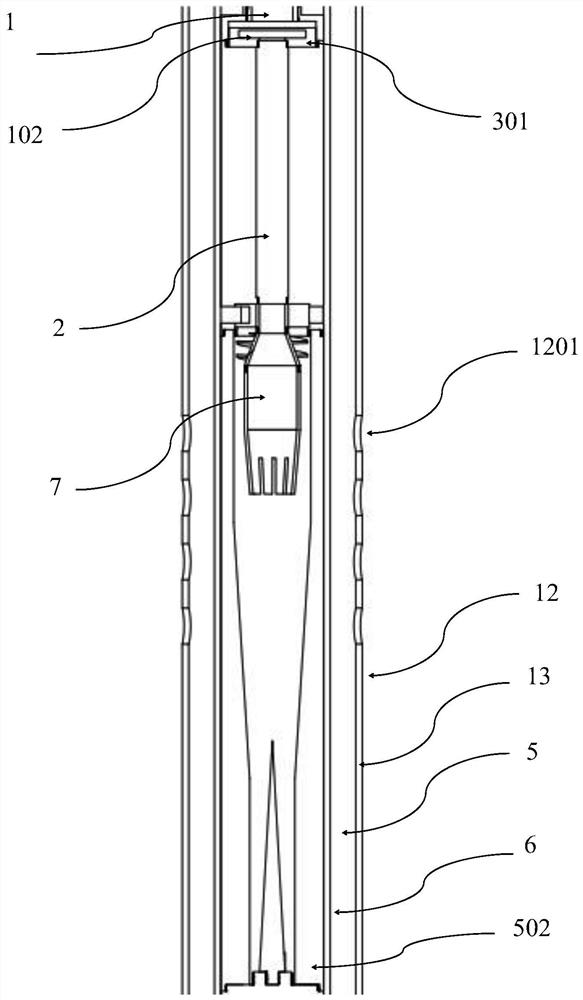

[0040] The present invention will be further described below in conjunction with the accompanying drawings:

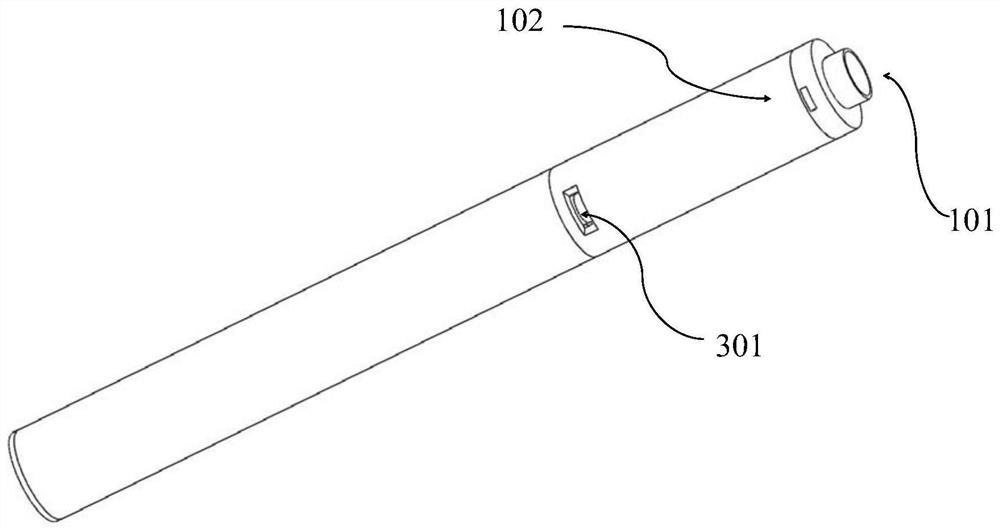

[0041] This type is suitable for downhole gas-liquid separation device of shale oil pumping unit oil production system. Cone, base.

[0042] The two ends of the liquid flow collection cover are concentric overlapping structures of cylinders of different diameters, and there is a bridge channel inside to allow the gas phase to be discharged to the annulus area of the oil jacket. The connection thread of the flow dividing cylinder and the connection thread of the gas guide pipe, the connection thread of the packer is connected with the packer through the thread in the downhole, so that the whole device runs under the protection of the packer, and the degassing bridge channel is inside the liquid flow collection cover The gas phase can be guided from the side to be discharged to the annular area of the oil jacket. The connection thread of the liquid flow dividing cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com