Adjustable supporting frame for boiler foundation bolts and mounting method

A technology of anchor bolts and support frames, which is applied in the field of adjustable support frames and installation of boiler anchor bolts, can solve the problems of affecting installation accuracy, low accuracy, and affecting accuracy, so as to achieve positioning difficulty and workload reduction, and improve accuracy And stability, the effect of reducing the difficulty of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

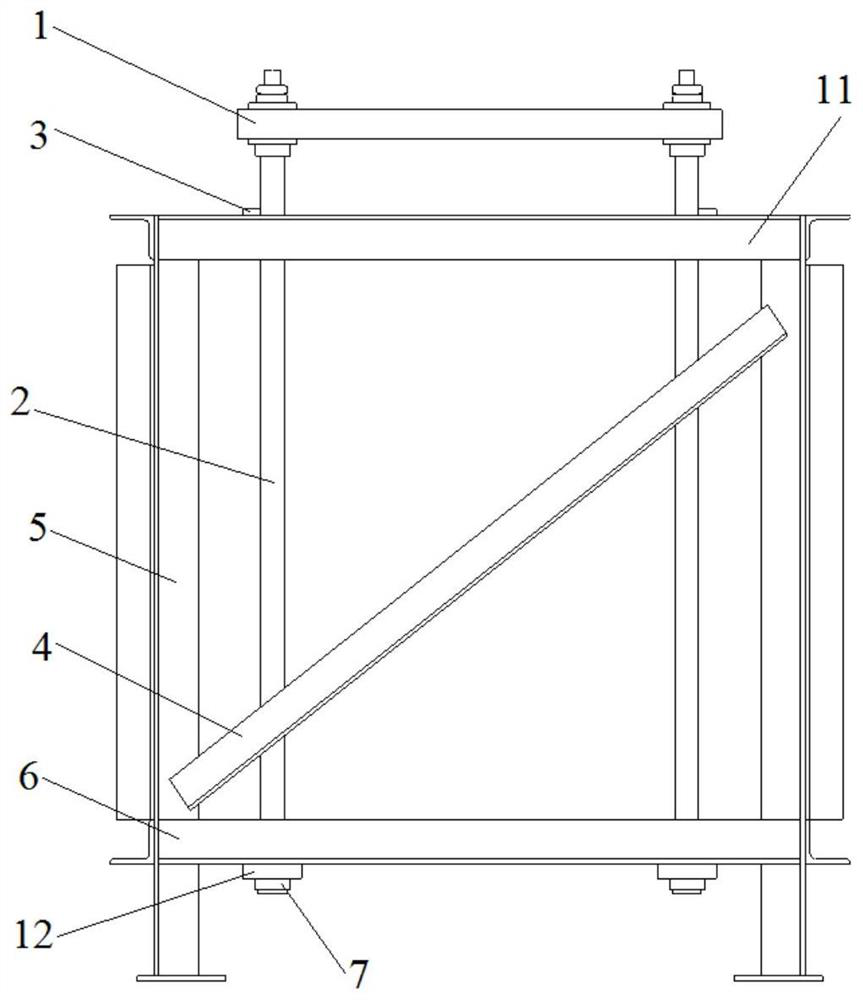

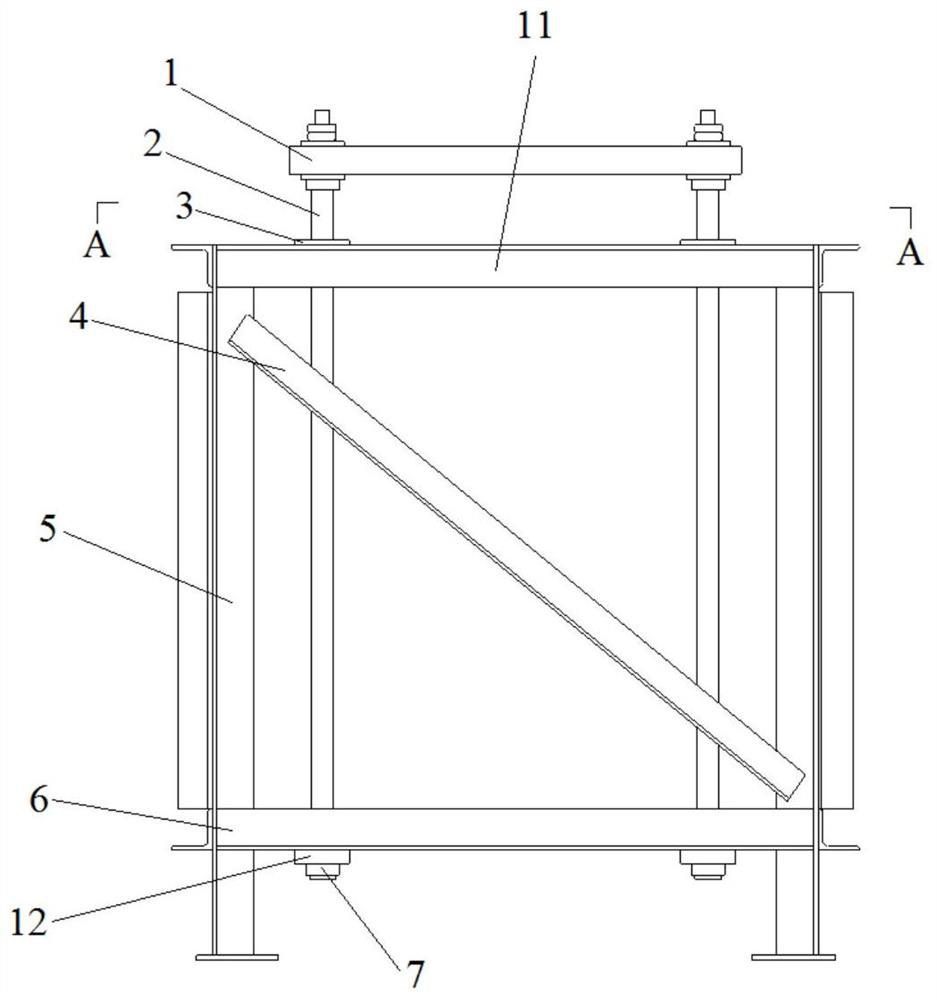

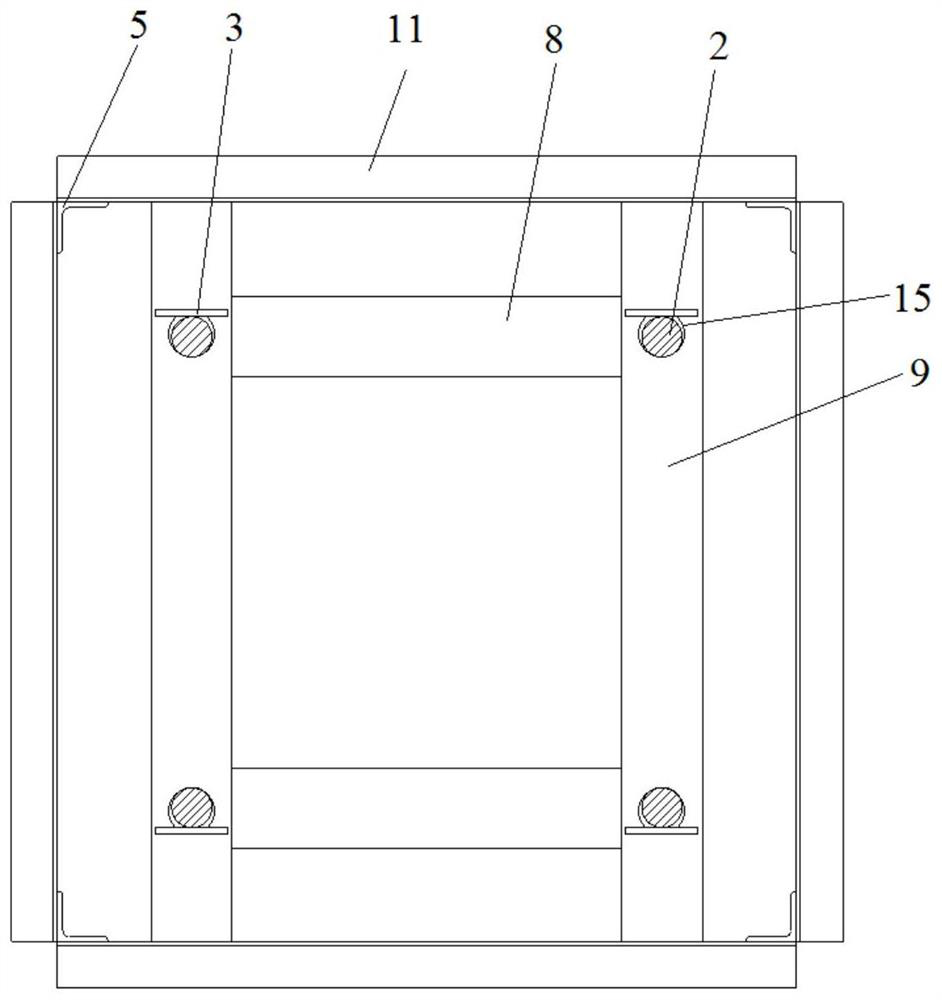

[0035] An adjustable support frame for boiler anchor bolts, used for positioning the anchor bolts 2, such as Figure 4 , Figure 5 , Image 6 with Figure 7 , including an outer frame and an inner frame, the outer frame includes four columns 5 arranged at four corners, an upper support beam 11 and a lower support beam 6 are connected between two adjacent columns 5, and the inner frame includes an upper positioning piece and a lower positioning piece , the upper positioning member includes two second upper positioning beams 9 arranged in parallel, the lower positioning member includes two second lower positioning beams 14 arranged in parallel, and the corresponding positions of the second upper positioning beam 9 and the second lower positioning beam 14 All are provided with positioning round holes 15, and the ends of the anchor bolts 2 pass through the positioning round holes 15 on the second upper positioning beam 9 and the second lower positioning beam 14 from top to botto...

Embodiment 2

[0040] An installation method using the adjustable support frame of the boiler anchor bolts in Embodiment 1, such as Figure 10 , including:

[0041] 1) Complete the fixing of the outer frame: determine the axis position of the outer frame, weld the column 5, the upper support beam 11 and the lower support beam 6, and complete the assembly of the outer frame;

[0042] 2) Complete the fixation of the inner frame: place the second upper positioning beam 9 on the upper supporting beam 11, pass the second lower positioning beam 14 from below the lower supporting beam 6, and place the lower end of the anchor bolt 2 from top to bottom. Pass through the positioning round hole 15 on the second upper positioning beam 9 and the second lower positioning beam 14 successively. After the position adjustment of the second upper positioning beam 9 and the second lower positioning beam 14 is completed, the second upper positioning beam 9 Fix by spot welding with the upper support beam 11, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com