A drying mechanism for gauze bandage scissors

A bandage and drying technology, which is applied in the field of medical equipment, can solve the problems of shortening the drying time of gauze bandages and the difficulty of drying gauze bandages, and achieves the effects of short drying time, energy saving and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

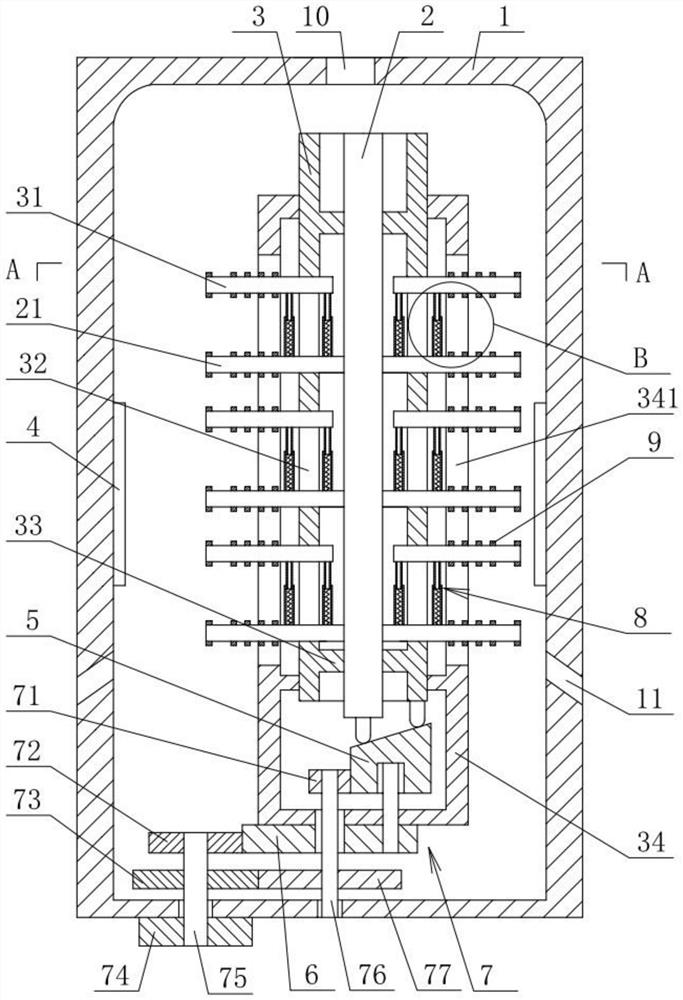

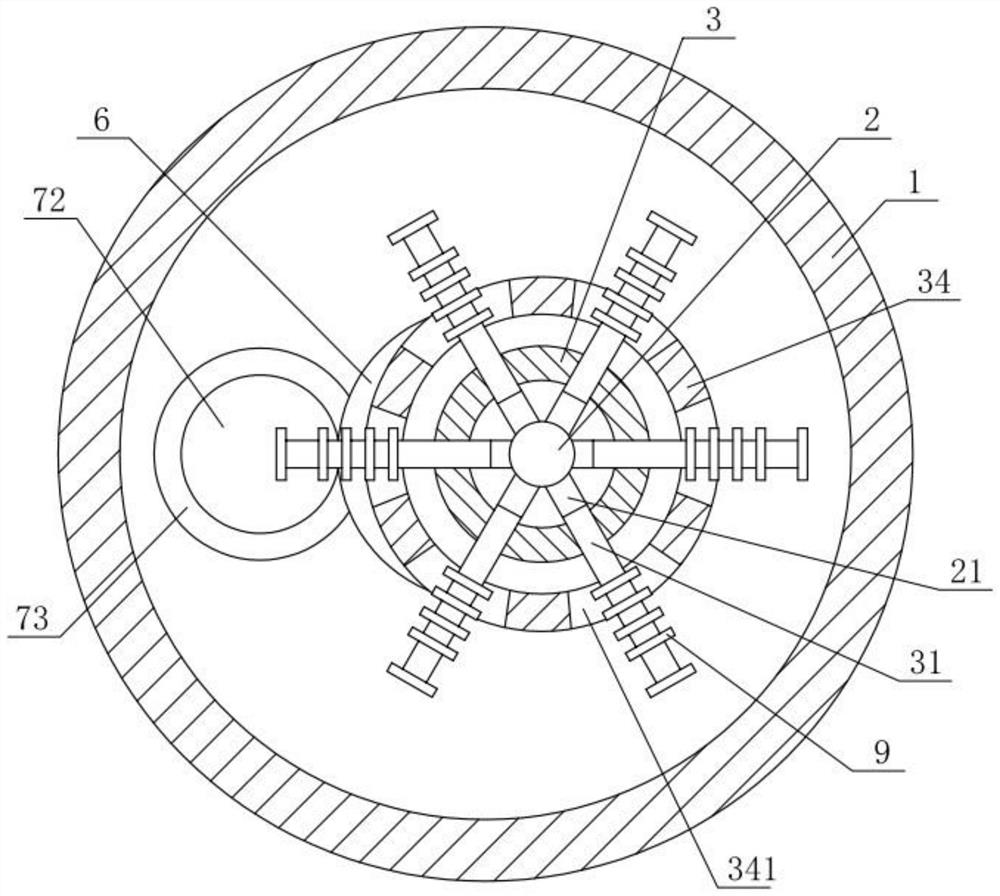

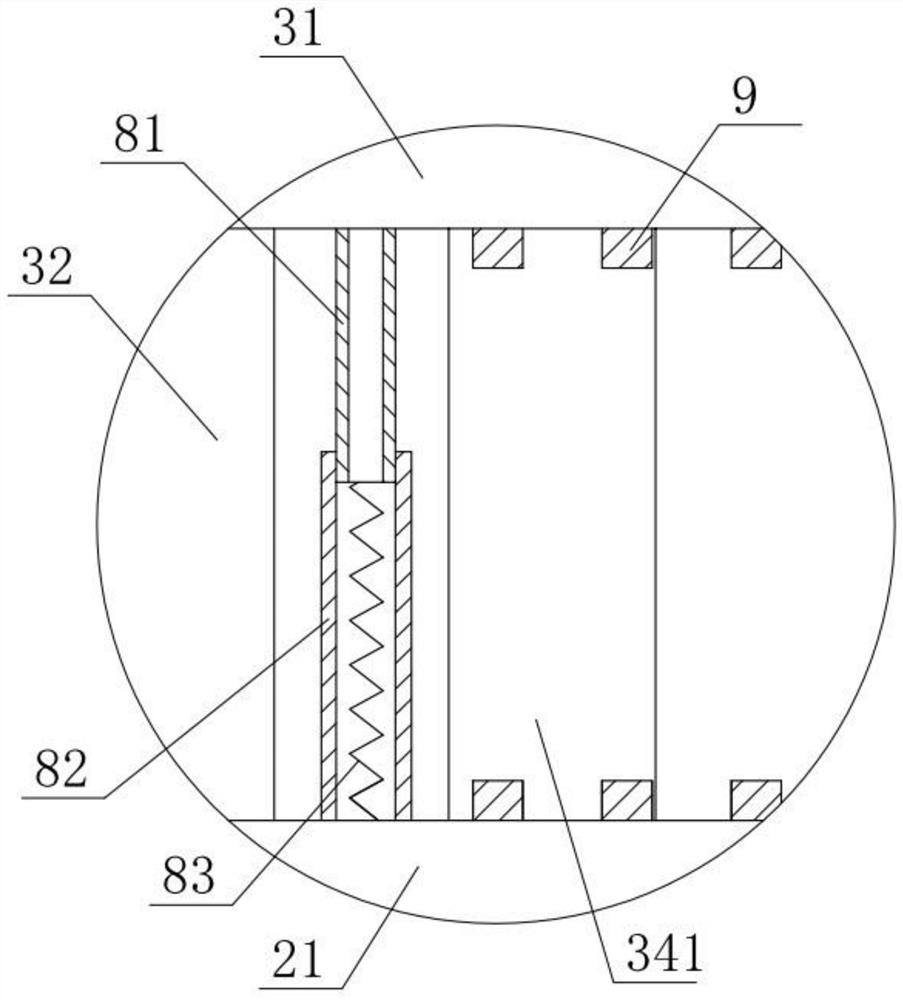

[0022] like figure 1 , 2 , 4, a drying mechanism for gauze bandage scissors, including a box body 1, a heater 4 is arranged on the side wall of the box body 1, a cylindrical rotating shaft 2 is arranged inside the box body 1, and a cylindrical shaft is connected to the outer shell of the rotating shaft 2 Sleeve 3, several strip-shaped first transverse rods 21 are fixedly connected to the side of the rotating shaft 2, and several strip-shaped second transverse rods 31 are connected to the shaft sleeve 3. The box body 1 is provided with a number of strip-shaped elastic members 8, and one end of the elastic member 8 is provided. It is fixed with the second cross bar 31, and the other end is fixed with the first cross bar 21. The box body 1 is provided with a turntable 6, and the turntable 6 is rotatably connected with a cam 5. , the turntable 6 is connected with a rotating mechanism 7 . The rotating mechanism 7 includes a cam power gear 71, a turntable power gear 72, a transiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com