Conveyor belt surface object image splicing method based on SIFT features

A technology of object images and conveyor belts, which is applied in the field of image processing, can solve problems such as pixel loss, time-consuming, and inability to meet industrial production inspection requirements, and achieve the effect of increasing calculation speed and reducing calculation amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

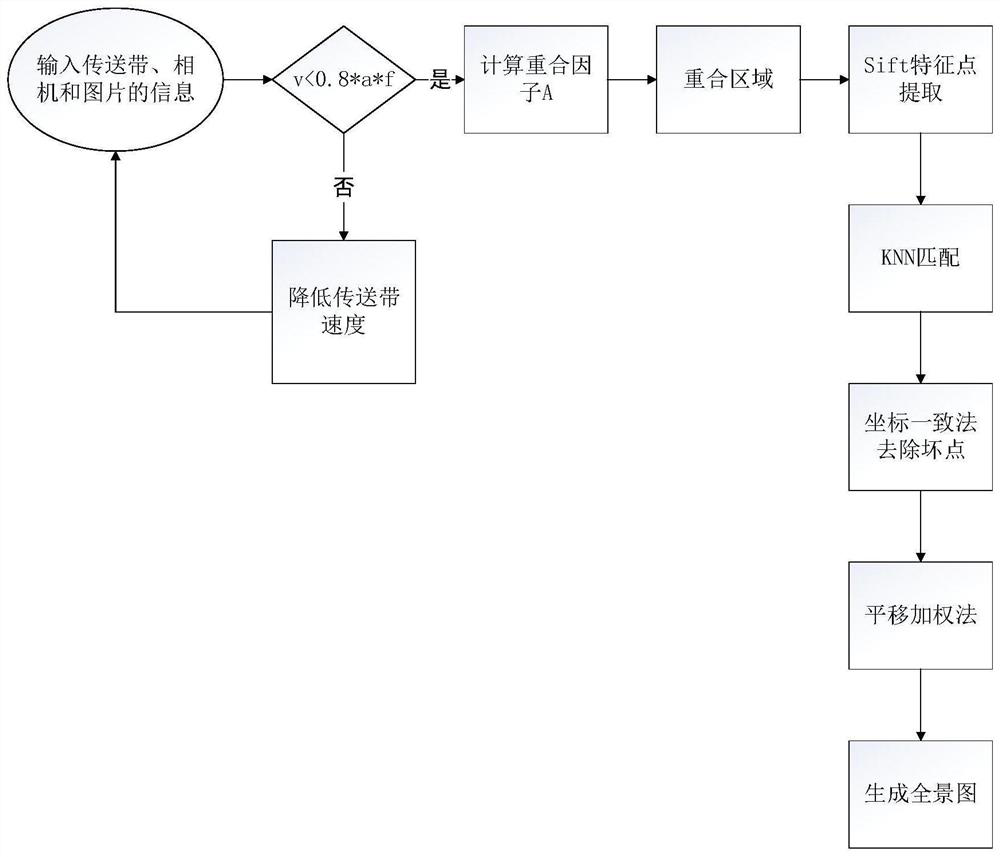

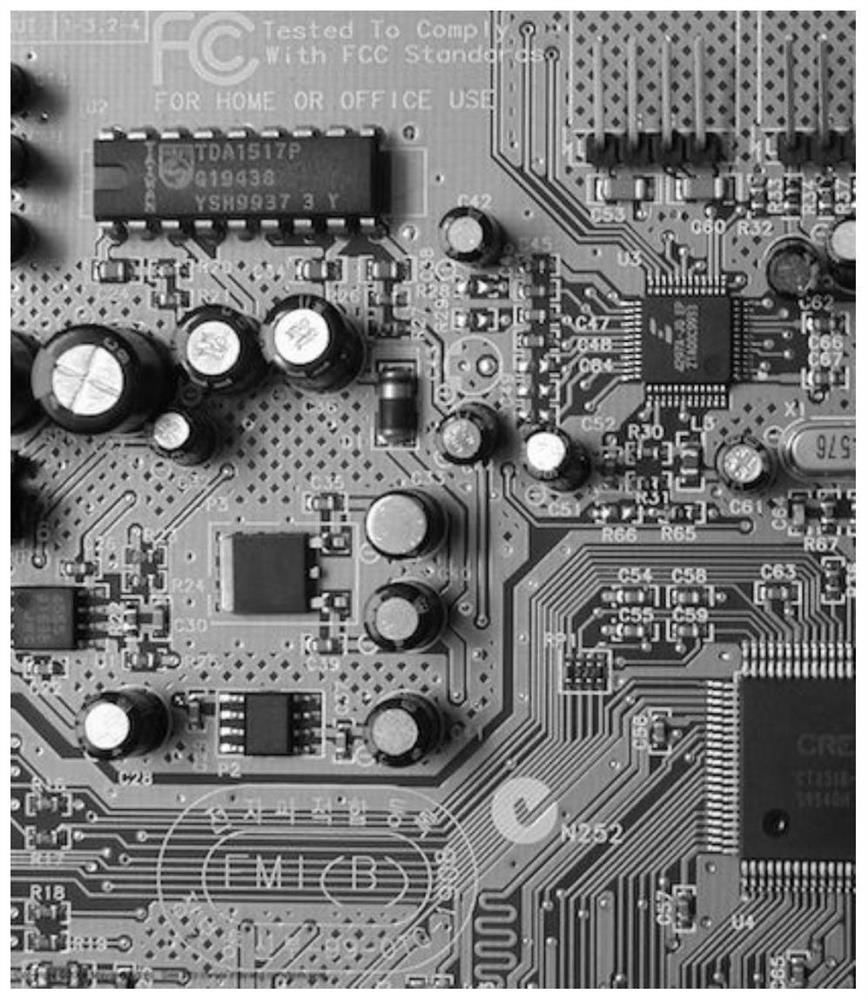

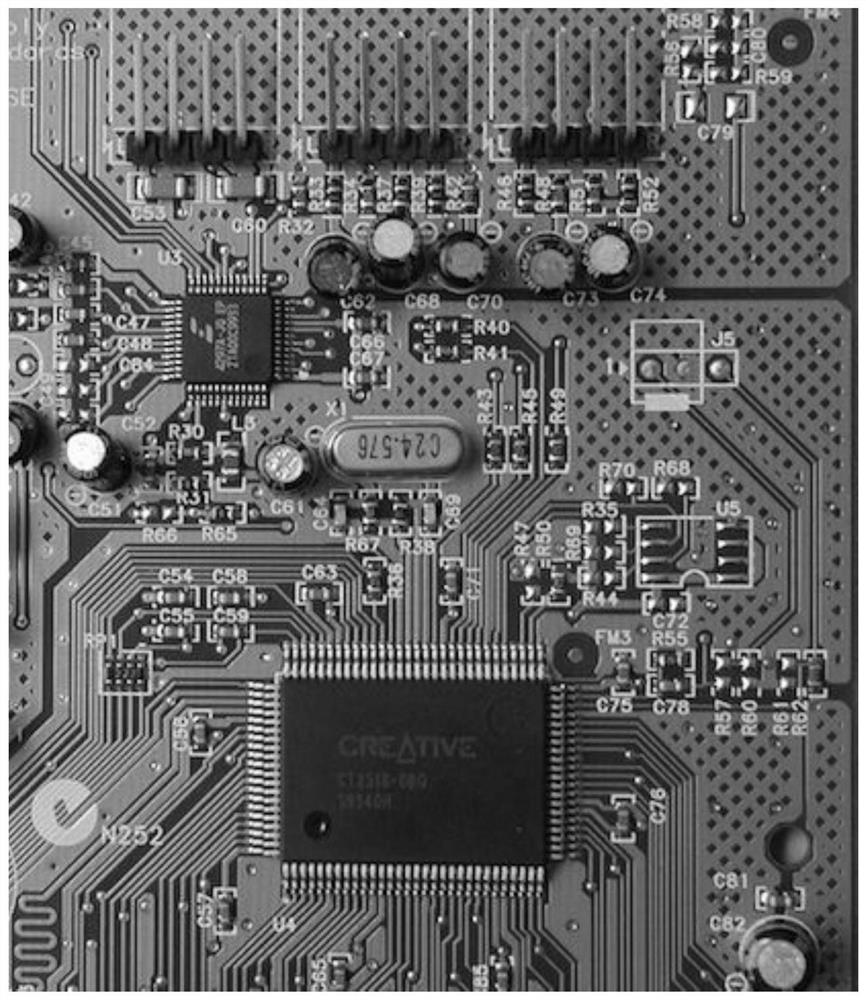

[0055] The preferred embodiment of the present invention provides a surface object image stitching method based on a SIFT feature, the method comprising: when the movement of the object is tested on the conveyor belt, the same camera is tested for the object to continuously shoot a multi-screening picture, the splicing method includes The following steps, through the speed of the conveyor, the coincident region of the adjacent two detection picture; provide feedback information to the conveyor belt, to adjust the size of the overlap region by adjusting the speed of the conveyor belt.

[0056] The extraction of the feature point is performed by the SIFT algorithm, and matches the knn algorithm to obtain a matching set m, and the bad point is removed for m using the coordinate consistency; seeking a translational distance, using a translation variable coefficient method Fusion, complete image stitching, overall steps figure 1 Indicated.

[0057] Among them, in step 1, the acquisitio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com