Rotor torsion inclination method suitable for permanent magnet synchronous motor

A technology for permanent magnet synchronous motors and rotors, which is applied in the direction of synchronous machine parts, magnetic circuit rotating parts, magnetic circuits, etc. It can solve the problems that the torque has not been eliminated to the greatest extent, limit the rotor distribution, etc., and achieve the weakening of torque harmonics Weight, optimize the effect of vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

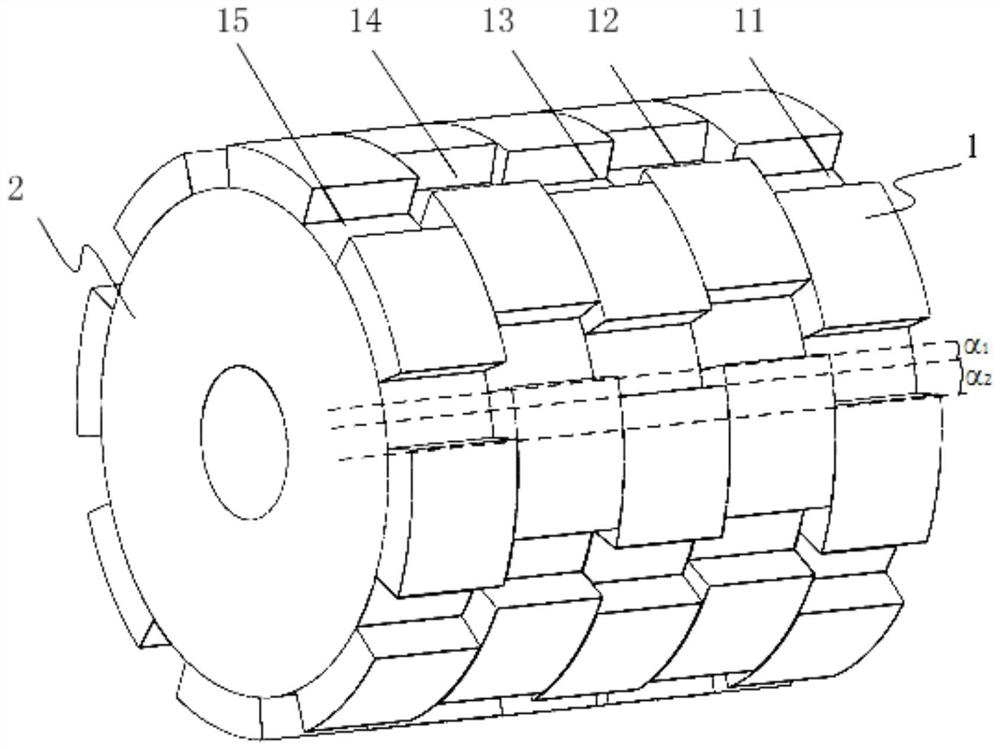

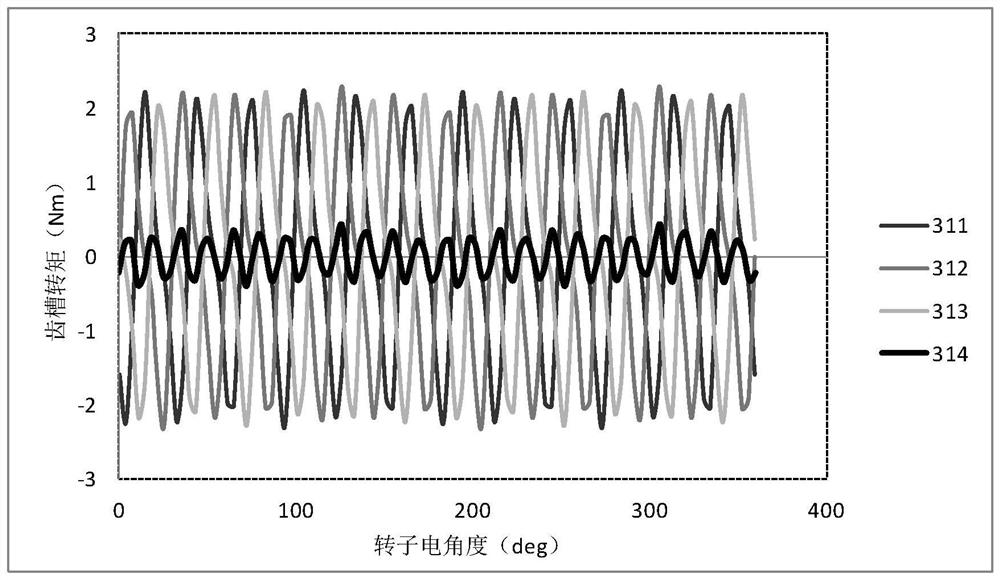

[0030] This application proposes a rotor torsional tilting method suitable for permanent magnet synchronous motors, in order to optimize vibration noise by freely matching two torsional tilting angles under specific magnetic field harmonics. The permanent magnet synchronous motor includes a coaxial stator and a rotor core 1 . One end of the rotor core 1 is provided with a magnetic steel 2, and the installation position of the magnetic steel 2 is not limited, including embedded or surface-mounted and all installation forms. The stator is a centralized or distributed winding. The method includes:

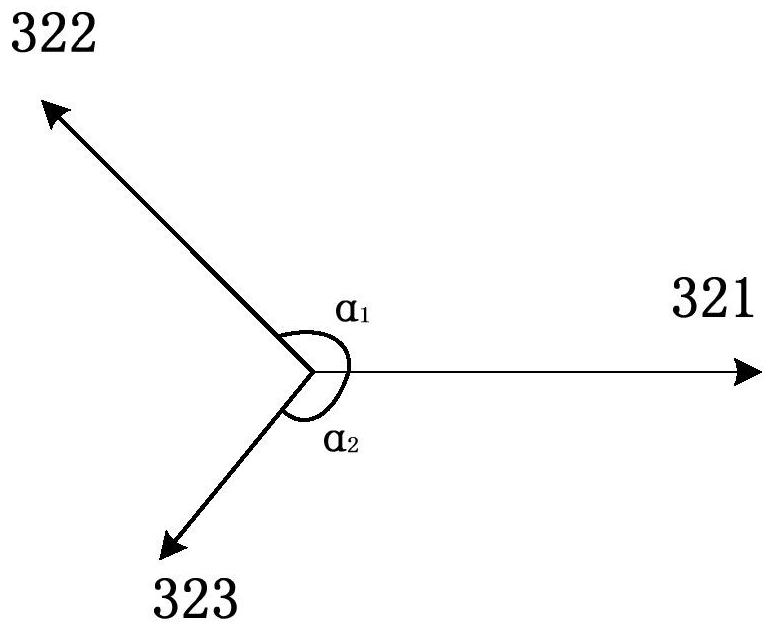

[0031] The rotor core 1 is divided into five sections of rotors with the same length in the axial direction. According to the number of pole pairs of the motor and the order of the harmonics of the magnetic field that need to be weakened, one section of the rotor is used as a reference, and the other four sections of rotors are rotated clockwise or counterclockwise. angle α 1 or al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com