Stator segmentation and rotor blade integrated high-speed asynchronous motor

A technology for asynchronous motors and blades, applied in asynchronous induction motors, liquid fuel engines, electromechanical devices, etc., can solve the problems of large fan diameter, integrated motor stator diameter, high manufacturing cost, etc., to reduce torque ripple, Improve the heat dissipation effect and reduce the difficulty of manufacturing and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A high-speed asynchronous motor integrated with stator segments and rotor blades of the present invention will be further described and explained below in conjunction with the drawings and embodiments.

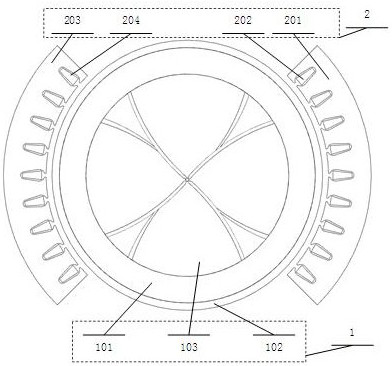

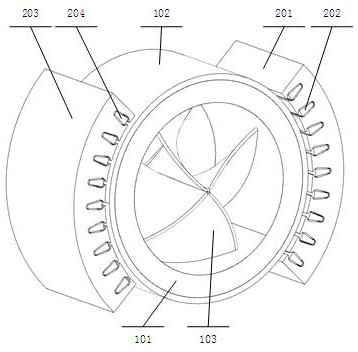

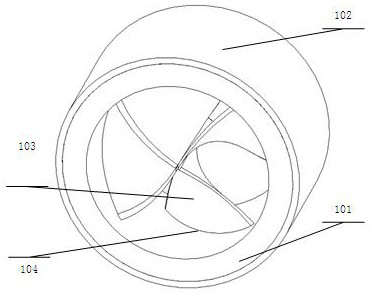

[0022] as attached figure 1 - attached Figure 4 shown, with figure 1 And attached figure 2 None include the magnetic suspension bearing system 3, attached Figure 4 Contains Magnetic Suspension Bearing System3. A high-speed asynchronous motor with segmented stator and integrated rotor and blades, including a slotless rotor 1 with integrated blades, a segmented winding stator 2, and a slotless rotor 1 integrated with fixed blades and a segmented winding stator (2) The relative position between the magnetic suspension bearing system 3. The blade-integrated slotless rotor 1 includes a rotor core 101 , blades 103 and conductor layers 102 , wherein the conductor layer 102 is arranged on the outer periphery of the rotor core 101 , and the blades 103 are uniformly arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com