Novel elastic waistline non-woven fabric and forming process thereof

A technology of elastic waistline and forming process, which is applied in the field of new elastic waistline non-woven fabric and its forming process, can solve problems such as lack of comfort, achieve the effects of reducing production costs, good use comfort, and reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

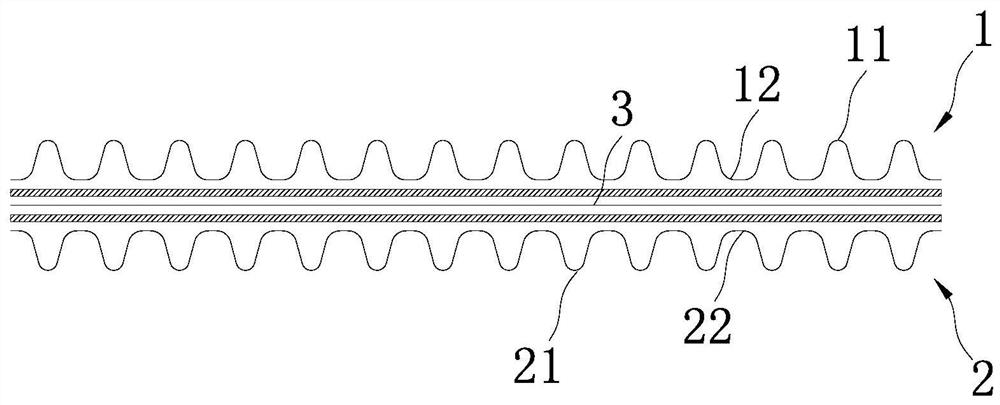

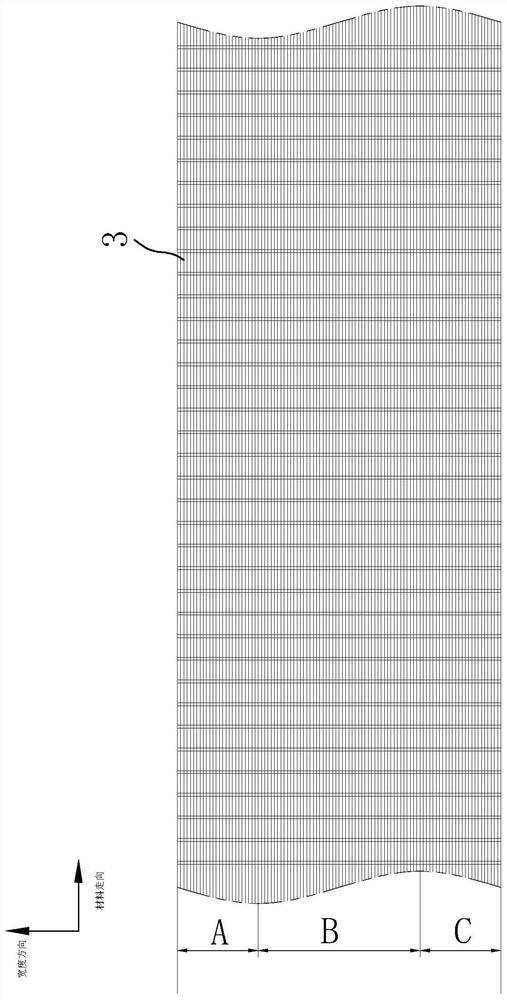

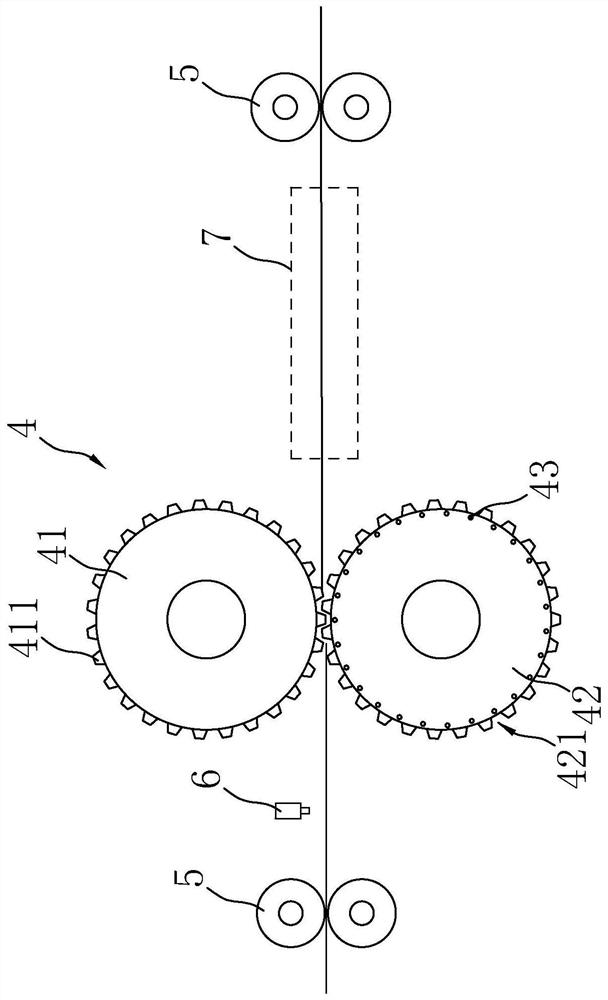

[0027] refer to figure 1 and figure 2 , a novel elastic waistline nonwoven fabric, comprising an upper layer elastic nonwoven fabric 1, a lower layer elastic nonwoven fabric 2 and an elastic element 3 sandwiched between them, the upper layer elastic nonwoven fabric 1 has a shape along its thickness direction It has a wavy linear structure with staggered upper crests 11 and upper troughs 12, and the lower elastic nonwoven fabric 2 has a wavy linear structure with staggered lower crests 21 and lower troughs 22 along its thickness direction , when the elastic element 3 is in a natural state of zero tension, the elastic element 3 is compounded on the upper wave trough 12 and the lower wave peak 21, and the composite position of each of the upper wave trough 12 and the lower wave peak 21 is Correspondingly, each of the upper wave crests 11 and each of the lower wave valleys 22 is not in contact with the elastic element 3; specifically, this embodiment adopts the form of hot melt ...

Embodiment 2

[0045] Such as Figure 4 As shown, compared with Example 1, it is another product structure that can realize the application scheme of the present invention. During production, the elastic element 3 is in a state of certain tension, and is elastic to the upper elastic nonwoven fabric 1 and the lower layer. Spray glue on the sandwiched surface of the non-woven fabric 2 to sandwich and adhere the elastic element 3. After the finished product, when the elastic element 3 is in a natural state of zero tension, each of the upper wave crests 11 and the lower wave crests 21. The compound positions of the upper valley portion 12 and the lower valley portion 22 correspond to each other. This is another production mode of this program, only production method is different, also can reach corresponding technical effect.

[0046] It should be pointed out that, in this embodiment, sizing and bonding are used for compounding, and ultrasonic welding or hot pressing can also be used for compou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com