Tobacco stem winnowing system with self-cleaning and dust-removing functions

A self-cleaning and winnowing technology, which is applied to the removal of smoke and dust, cleaning methods and utensils, tobacco, etc., can solve the problems of large dust, easy blockage of dust filter, damage to the health of front-line workers, etc., to ensure purity and prevent equipment blockage , Improve the effect of the production site environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

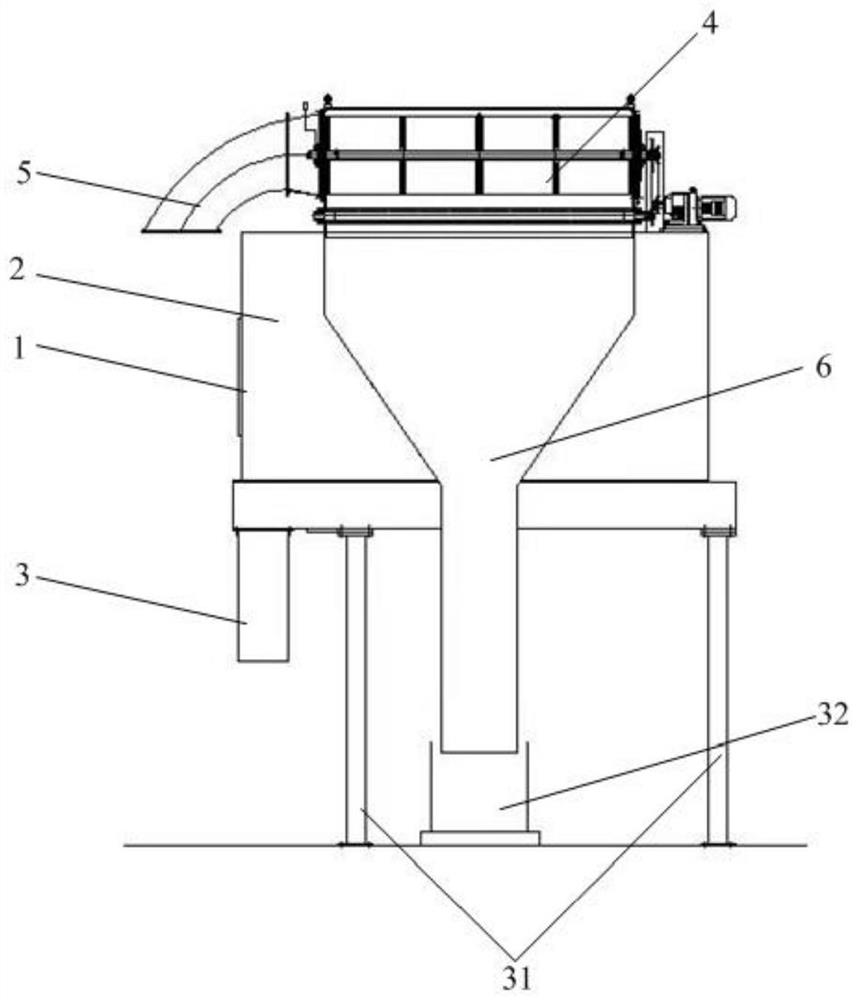

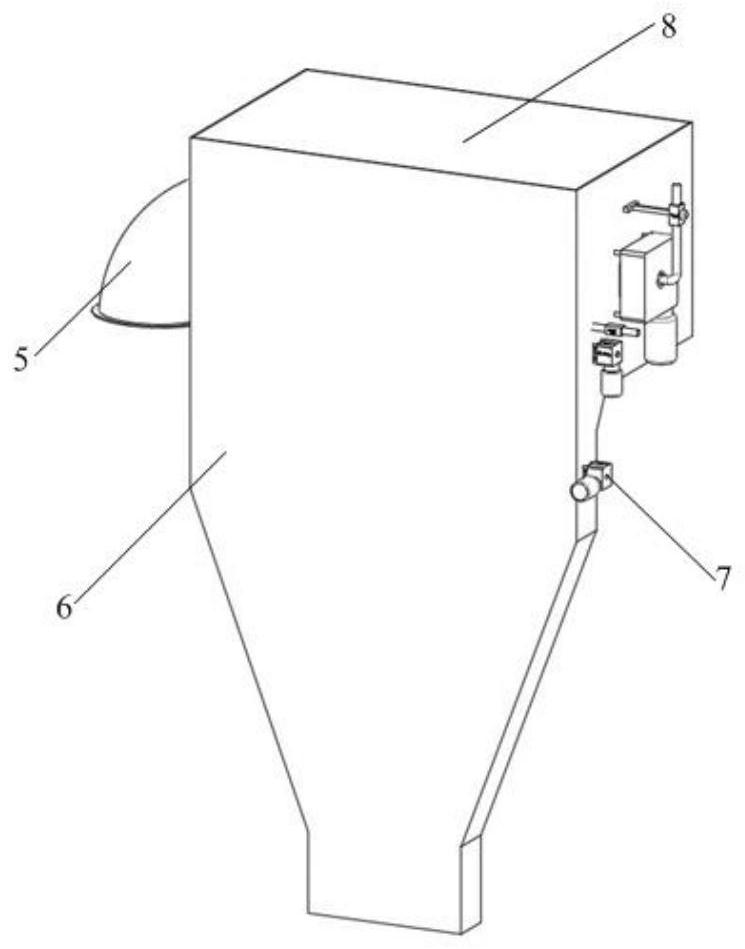

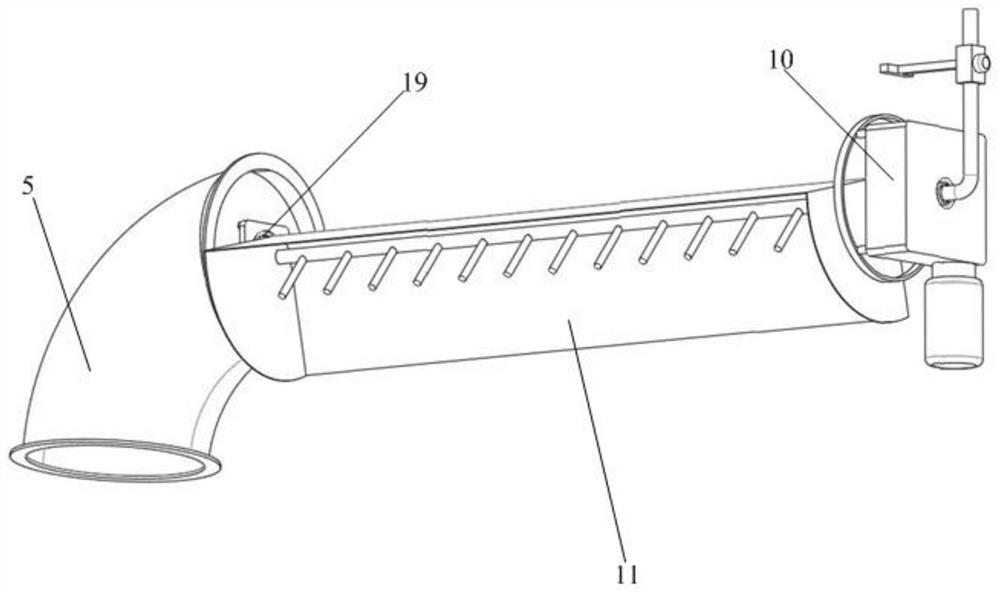

[0025] Embodiments of the present invention: as Figure 1-8 As shown, a tobacco stem winnowing system with self-cleaning and dust removal function includes a feed inlet 1, a winnowing box body 2 and a tobacco stem outlet 3, and the feed inlet 1 is arranged on the side wall of the winnowing box body 2 Above, the tobacco stem discharge port 3 is located at the bottom of the winnowing box body 2, and is located on the same side as the feed port 1, in order to make the tobacco stems can be smoothly discharged from the tobacco stem discharge ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap