Disinfection and sterilization method before filling of transparent plastic beverage bottle

A technology of disinfection and sterilization, transparent plastic, applied in the direction of disinfection, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of increasing the secondary pollution of plastic beverage bottles, increasing the workload of employees, and low cleaning efficiency, so as to avoid The effect of water accumulation, increasing secondary pollution and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

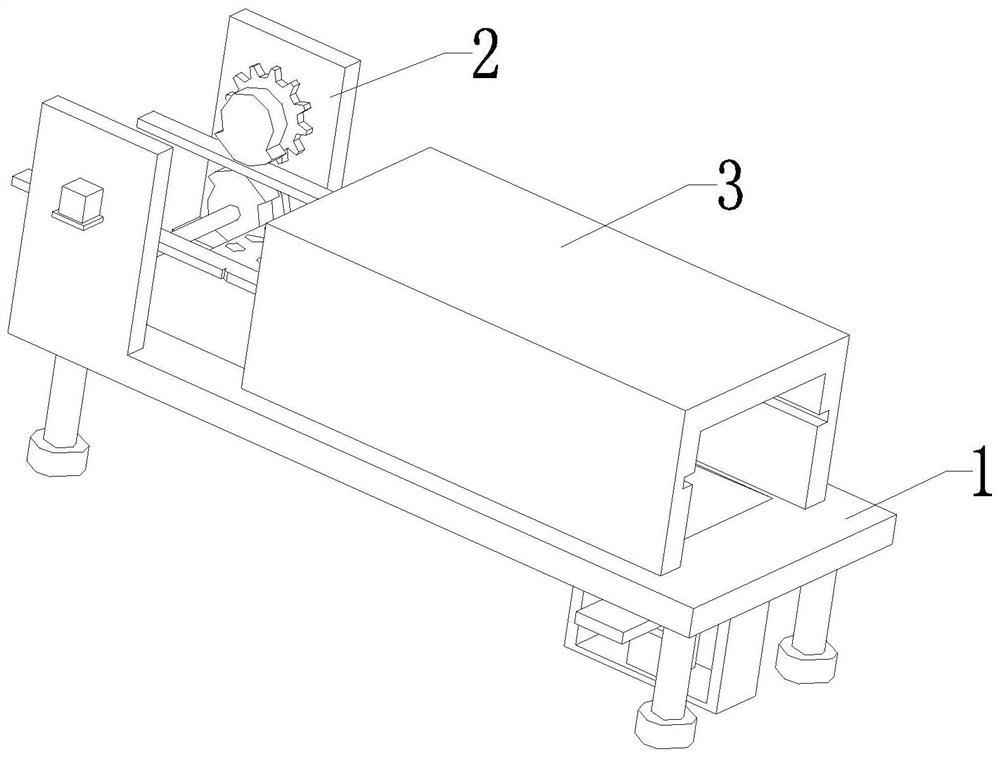

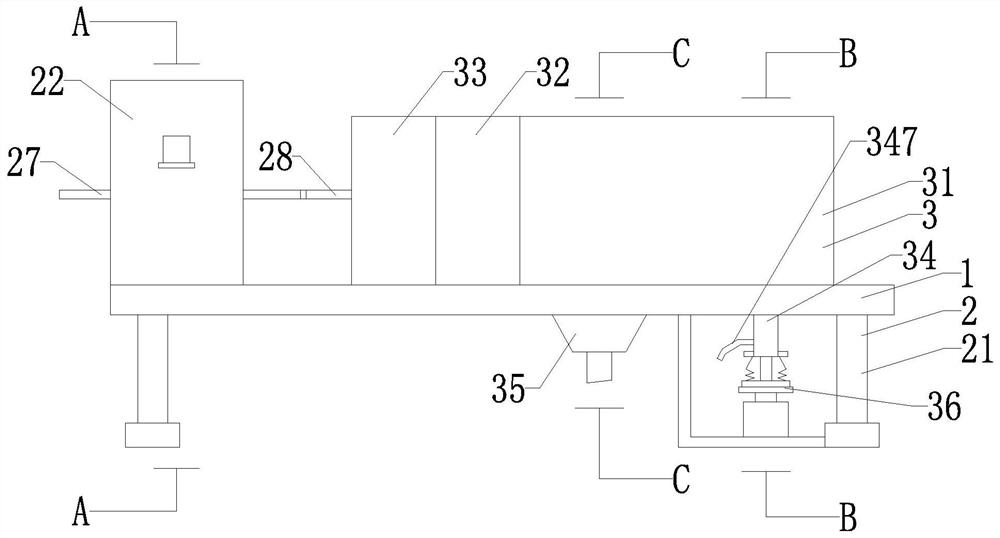

[0032] The embodiments of the present invention are described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

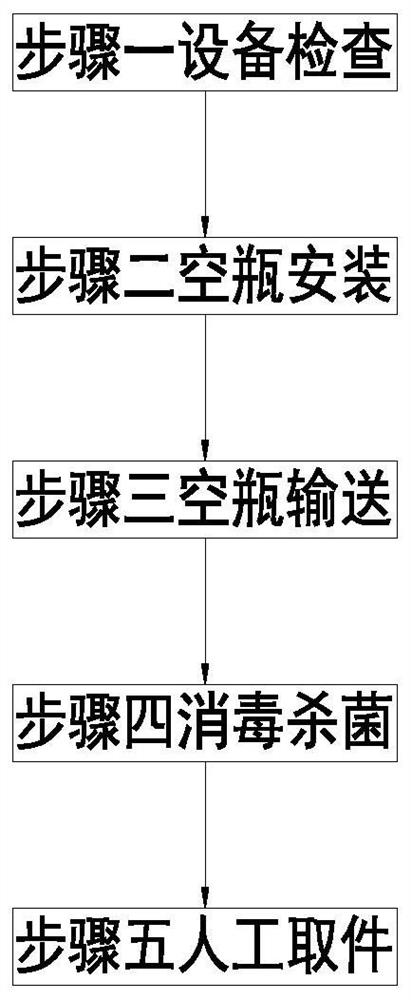

[0033] like Figure 1 to Figure 8 As shown, a method for sterilizing and sterilizing a transparent plastic beverage bottle before filling mainly includes the following steps:

[0034] Step 1: Equipment inspection: Before enabling the transparent plastic beverage bottle disinfection and sterilization equipment to sterilize the transparent plastic beverage bottle, check the operation of the equipment;

[0035] Step 2: Empty bottle installation: Manually place the transparent plastic beverage bottle that needs to be sterilized on the material holding plate 28 with the cup mouth facing down, and the material holding plate 28 works to fix the transparent plastic beverage bottle, so as to achieve an empty the purpose of the bottle installation;

[0036]S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com