Tubular part forming method and tubular part forming device

A technology of parts and tube shapes, which is applied in the field of tube parts forming methods and devices, can solve problems such as the lack of research on liquid filling forming technology, achieve good development potential, improve material forming performance, and reduce the hydraulic tonnage of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

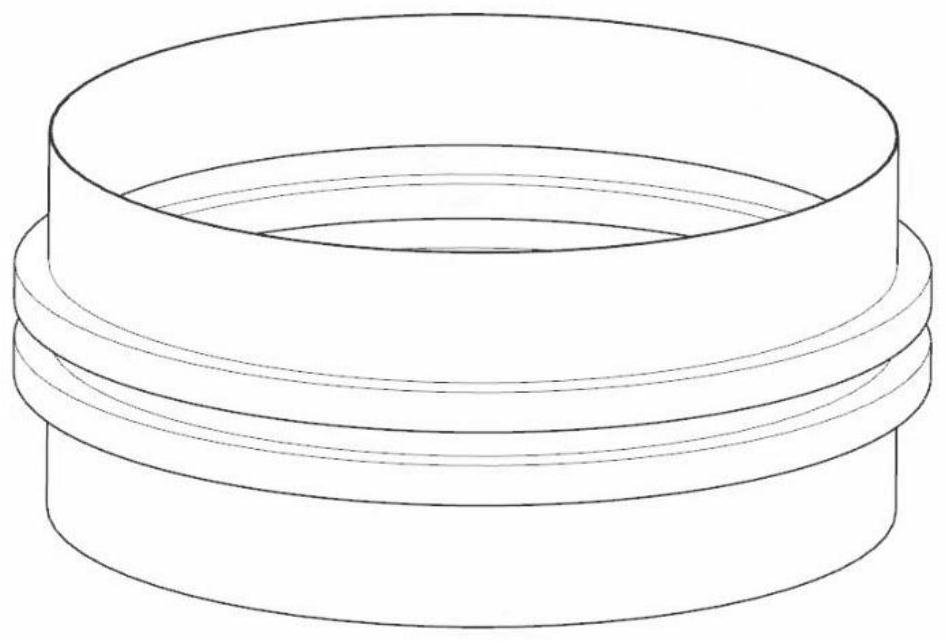

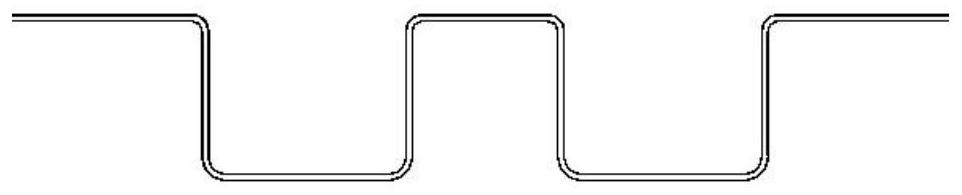

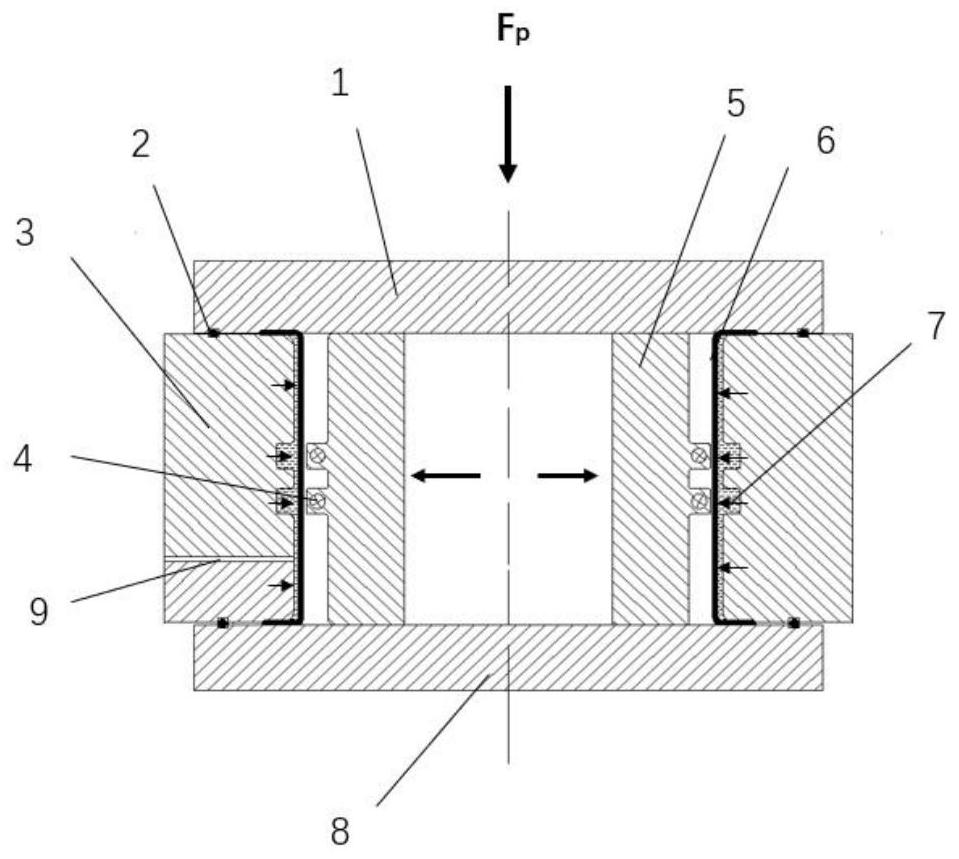

[0039] A tubular part forming device, comprising an upper backing plate 1, a lower backing plate 8, a rigid die 3 and a mold insert 5, wherein the upper backing plate 1 and the lower backing plate 8 are arranged in parallel from top to bottom, and the mold insert 5 and the rigid die 3 are respectively vertically arranged between the upper backing plate 1 and the lower backing plate 8, and the cavity of the rigid die 3 matches the protrusion of the mold insert 3, and the cavity side of the rigid die 5 A liquid chamber cavity 7 is provided, a liquid inlet 9 is provided at the bottom, and a heating ring 4 is provided in the protrusion of the mold insert.

[0040] In this embodiment, sealing rings 2 are respectively arranged between the rigid die 3 and the upper backing plate 1 and the lower backing plate 8 .

Embodiment 2

[0042] The part forming method using the tubular part forming device provided in the above-mentioned embodiment 1 comprises the following steps:

[0043] 1) Inspect the material grade, state, specification and surface quality of the parts through the bill of materials and measuring tools;

[0044] 2) According to the required size, the material of the part is rolled and welded, and the tolerance is 0-0.5mm;

[0045]3) Carry out cutting treatment on the tube billet according to the need, inspect the outer dimension and surface quality of the tube billet after cutting, and then put it into a vacuum heat treatment furnace for annealing treatment;

[0046] 4) After annealing, clean the inner and outer surfaces of the tube blank and the oil stains on the mold surface with a cotton rag;

[0047] 5) Flanging the tube blank according to the preset flanging forming process;

[0048] 6) Clean the key surface and the oil stains on the mold surface with a cotton rag, and check the key d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com