Grid type stackable tray structure of sintering equipment of environment-friendly material yard

A technology of sintering equipment and mesh format, which is applied in the field of stackable tray structures in mesh format, can solve the problems of easy inclination, spillage of materials, inability to add reinforcement structures, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

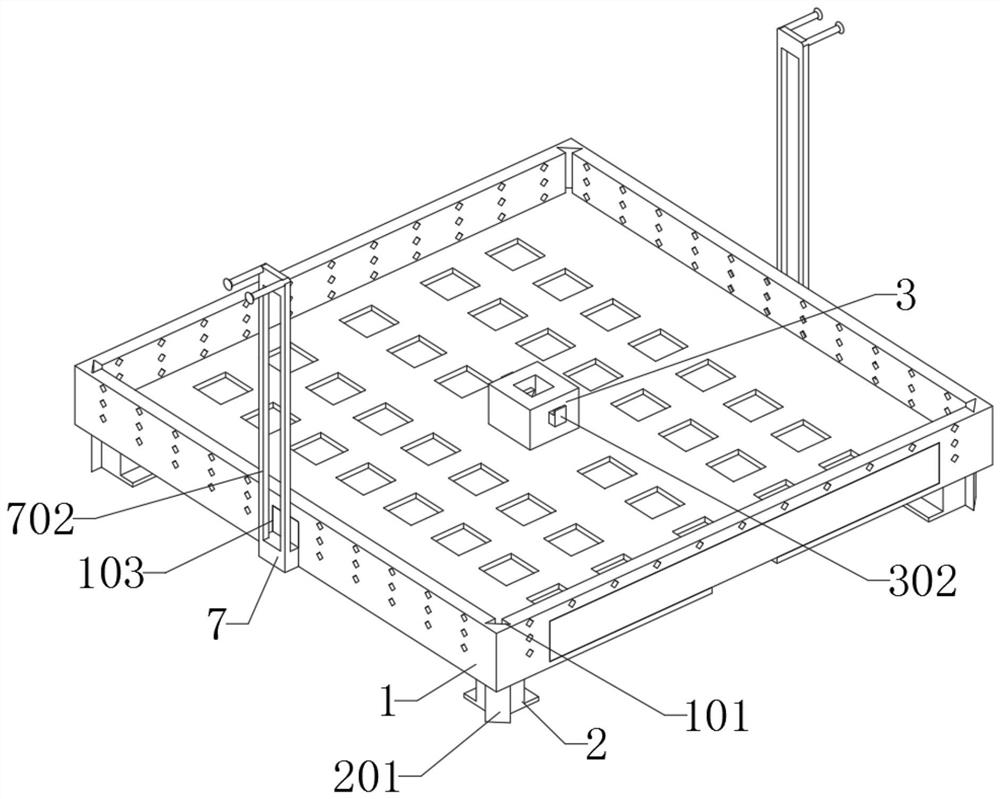

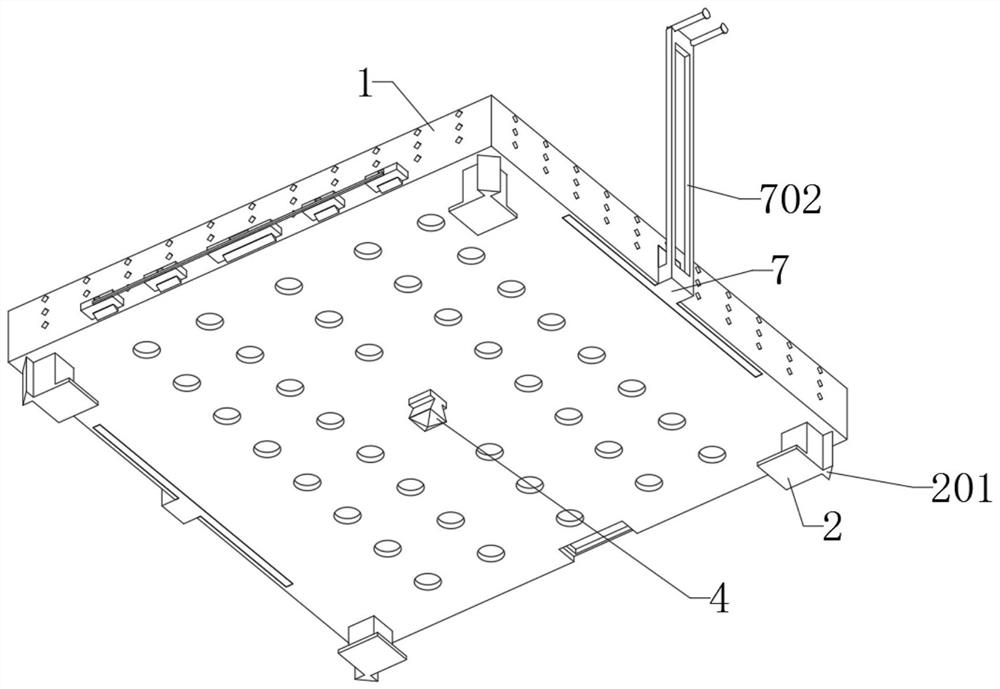

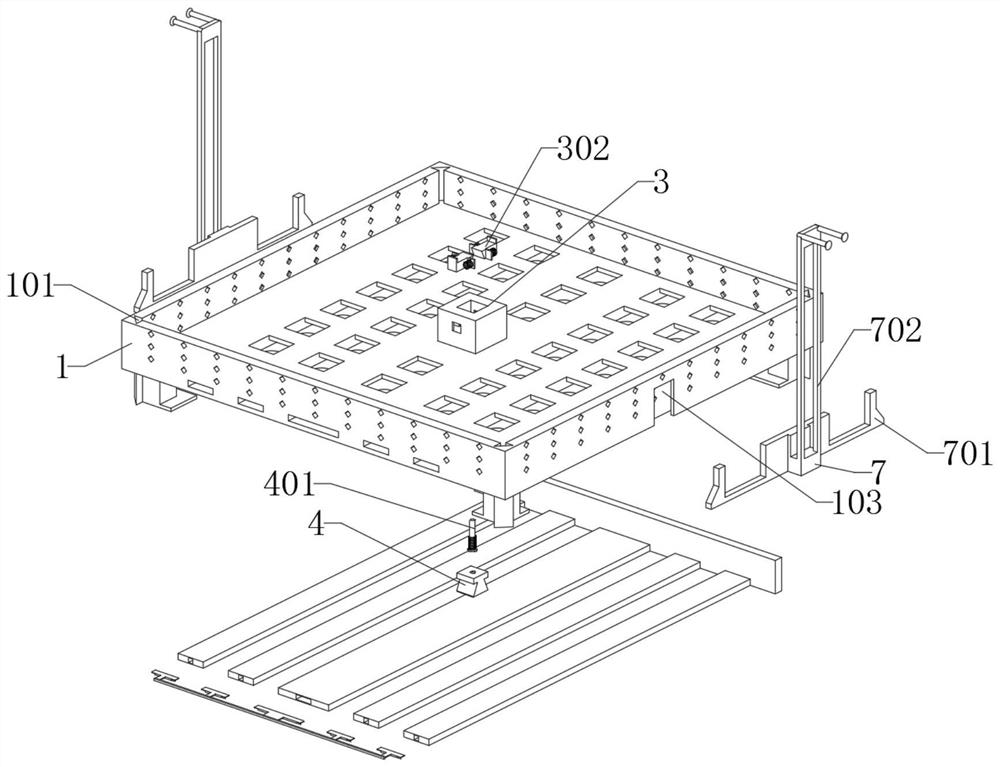

[0034] as attached figure 1 to attach Figure 8 Shown:

[0035]The invention provides a stackable grid tray structure for sintering equipment used in an environmental protection stockyard, including a main body 1, a support part 2, an inner part 3, a force bearing head 4, a side plate 5, a control plate 6 and an insert part 7; the main body 1 is a rectangular structure, and the inside of the top of the main body 1 is a rectangular structure, and the outside and bottom of the main body 1 are provided with a rectangular grid; Fixed connection; the inner part 3 is fixedly installed at the middle position of the top of the main body 1; the force bearing head 4 is at the bottom middle position of the main body 1, and the top of the pull rod 401 of the force bearing head 4 is connected with the bottom middle position of the main body 1; the side plate 5 is on the right side of the side slot 102, and the insert plate 501 of the side plate 5 is inserted and installed at the inner bo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap