Mixed refrigerant for replacing R507A

A mixed refrigerant, mass percentage technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of low refrigeration performance, weak flammability, and charging volume can not exceed 1.2kg, and achieve the effect of safety guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

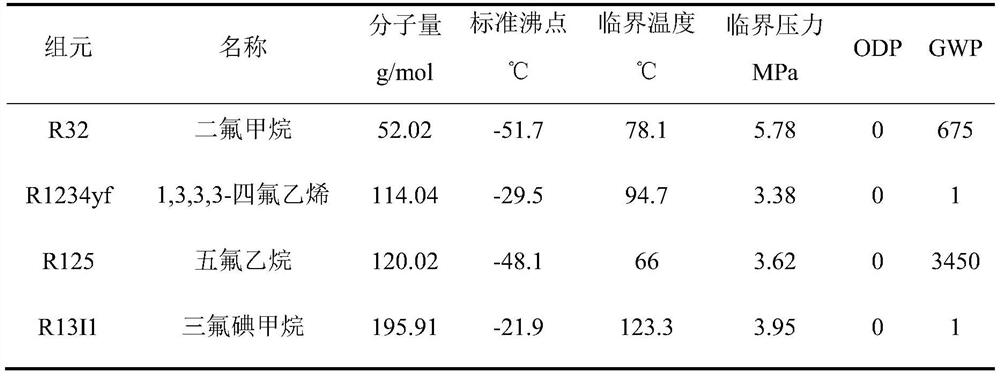

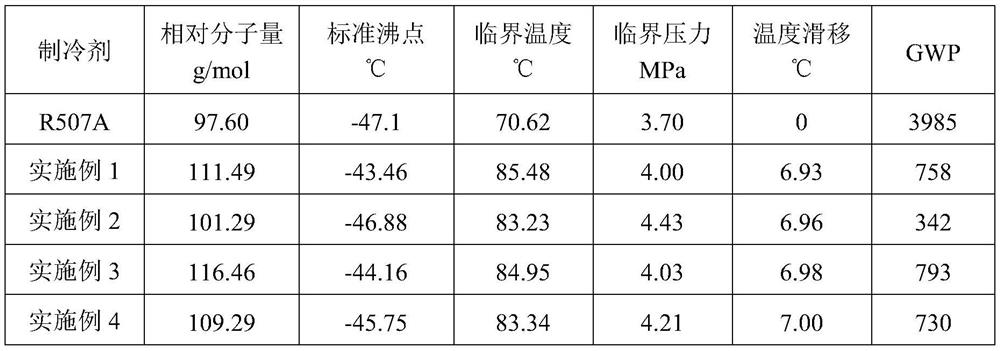

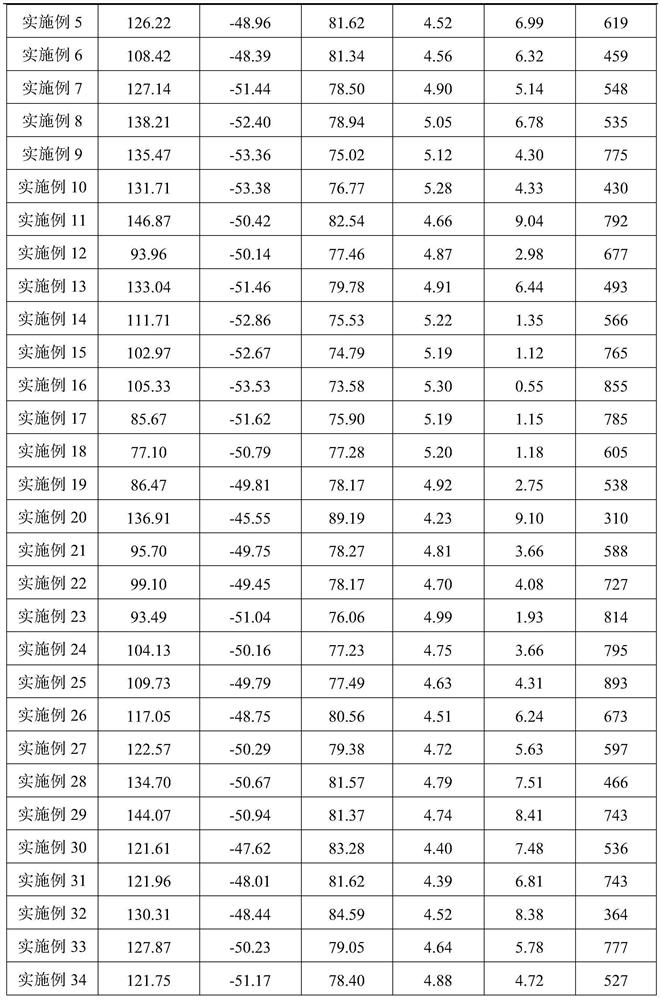

[0025] The preparation method of the mixed refrigerant of the present invention is to physically mix the four component substances according to their designated mass percentages at normal temperature. The basic physical properties of the four components are shown in Table 1:

[0026] Table 1 The basic parameters of the four components of difluoromethane, 1,3,3,3-tetrafluoroethylene, pentafluoroethane and trifluoroiodomethane include: Tb: normal boiling point, Tc: critical temperature, Pc: critical pressure

[0027]

[0028] Preferably, in terms of mass percentage, it includes 18% to 55% of difluoromethane, 15% to 48% of 1,3,3,3-tetrafluoroethylene, 7% to 18% of pentafluoroethane and 8 %~42% trifluoroiodomethane.

[0029] Preferably, in terms of mass percentage, it includes 30% to 45% of difluoromethane, 15% to 48% of 1,3,3,3-tetrafluoroethylene, 7% to 18% of pentafluoroethane and 8 %~42% trifluoroiodomethane.

[0030] Preferably, in terms of mass percentage, it includes ...

Embodiment 1

[0039] R32 (difluoromethane), R1234yf (1,3,3,3-tetrafluoroethylene), R125 (pentafluoroethane) and R13I1 (trifluoroiodomethane) four components under normal pressure by 10% / The mass percentage of 67% / 20% / 3% is uniformly mixed by general physical method to obtain a mixed refrigerant.

[0040] Assuming that the total mass of the mixed refrigerant is X, multiply X by 10% of R32 (difluoromethane), X by 67% of R1234yf (1,3,3,3-tetrafluoroethylene), and X by 20% The four components of R125 (pentafluoroethane) and X multiplied by 3% of R13I1 (trifluoroiodomethane) are uniformly mixed by general physical methods under normal pressure to obtain a mixed refrigerant. The following expressions are analogous.

[0041] R32 is the code name of the refrigerant difluoromethane, R1234yf is the code name of the refrigerant 1,3,3,3-tetrafluoroethylene, R125 is the code name of the refrigerant pentafluoroethane, and R13I1 is the code name of the refrigerant trifluoroiodomethane.

Embodiment 2

[0043]R32 (difluoromethane), R1234yf (1,3,3,3-tetrafluoroethylene), R125 (pentafluoroethane) and R13I1 (trifluoroiodomethane) four components under normal pressure by 25% / 67% / 5% / 3% by mass, mixed uniformly by general physical methods to obtain a mixed refrigerant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com