CO2/R170 azeotropic refrigerant

A technology of R170 and refrigerants, applied in the field of azeotropic refrigerants, can solve the problems of refrigerant flow control imbalance, waste, and unsafe operation of the system, and achieve low GWP value, low flammability, great application value and market prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

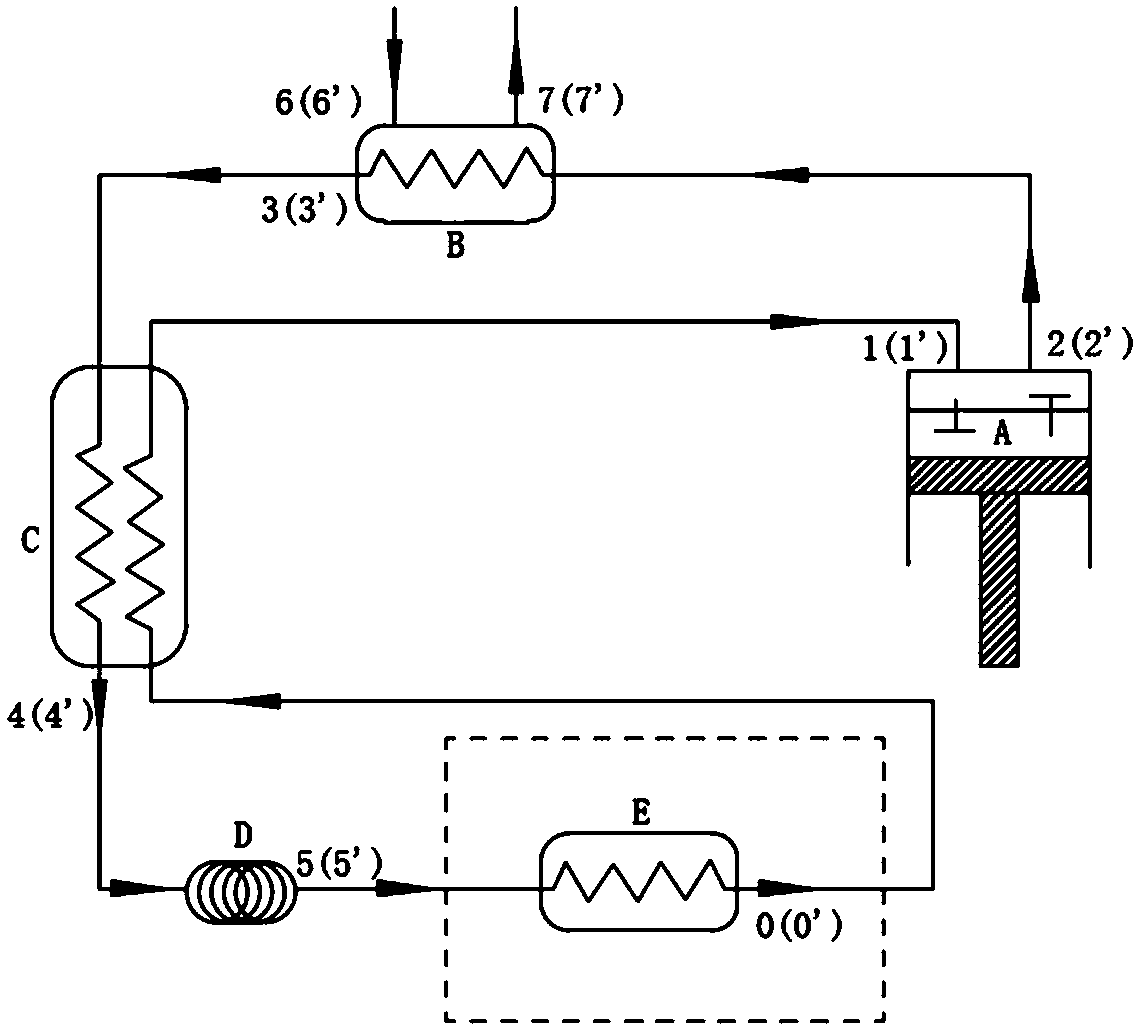

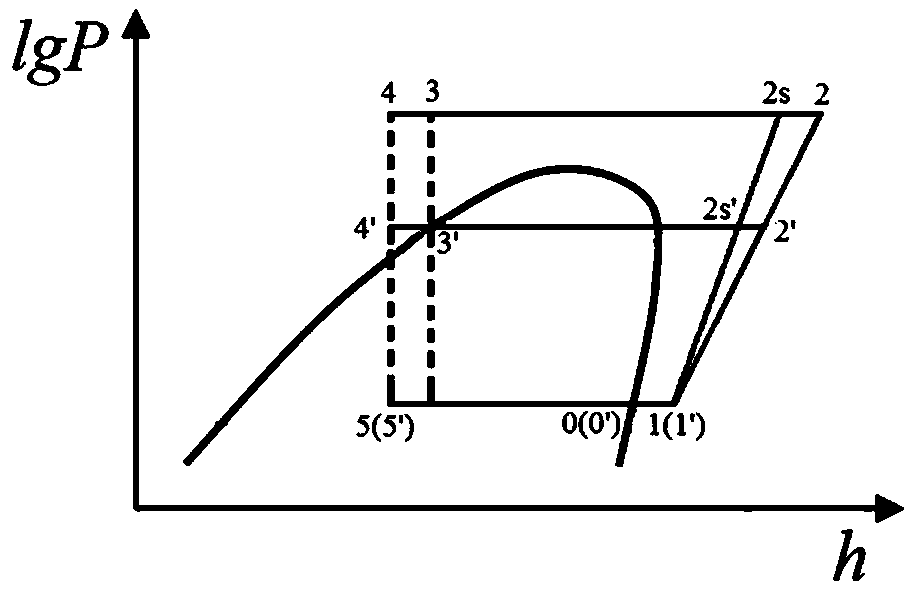

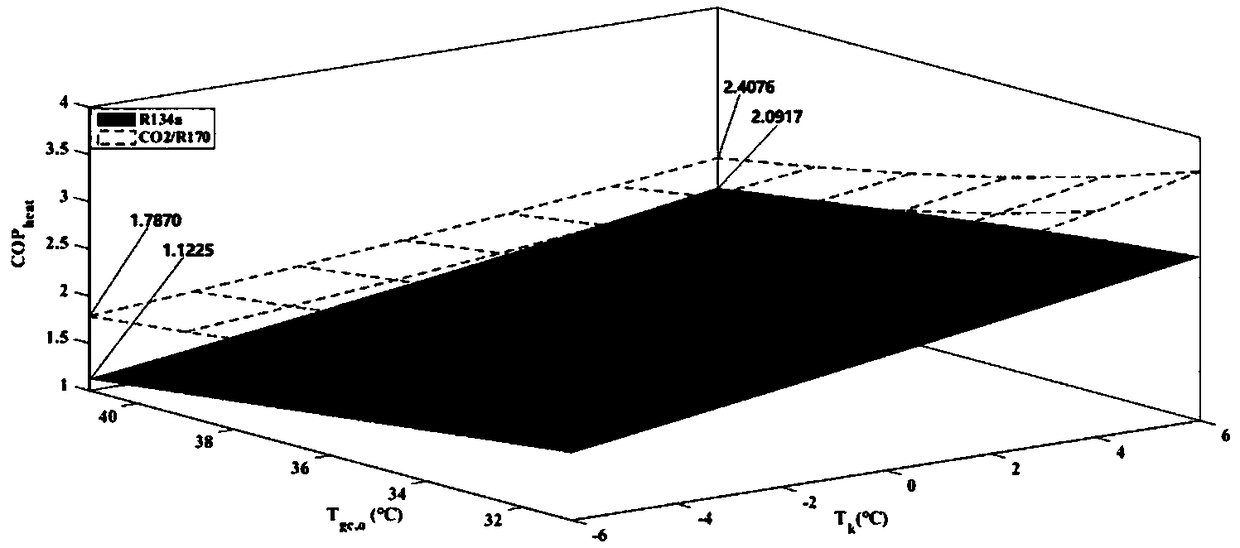

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described and illustrated through specific examples below.

[0030] CO 2 It is a linear symmetrical molecule without polarity. R170 has a staggered (or sloped) configuration, which has very weak polarity. According to the principle of like dissolves like, they can be mixed in any proportion. CO 2 The C=O bond in the molecule, the C-H bond in the R170 molecule is difficult to break. Therefore, CO 2 The chemical properties of R170 and R170 are stable, and no chemical reaction will occur when they are mixed as refrigerants used in air-conditioning and heat pump systems. CO 2 / R170 binary mixture is an azeotropic mixture of appropriate mass ratio components. To determine the proportions of the components of the azeotrope, CO 2 The temperature glide of / R170 binary mixture is calculated by REFPROP9.0. The calculation results are shown in Table 1, CO 2 When the mass ratio is 78% to 80.6%, CO 2 The tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com