Refrigerant added with amide compatibilizer and preparation method thereof

A technology of compatibilizer and amide, which is applied in the field of refrigerant and its preparation with the addition of amide compatibilizer. Problems such as equipment investment and energy consumption, to achieve the effects of industrial mass production, good solubility and diffusivity, and reduced flammability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

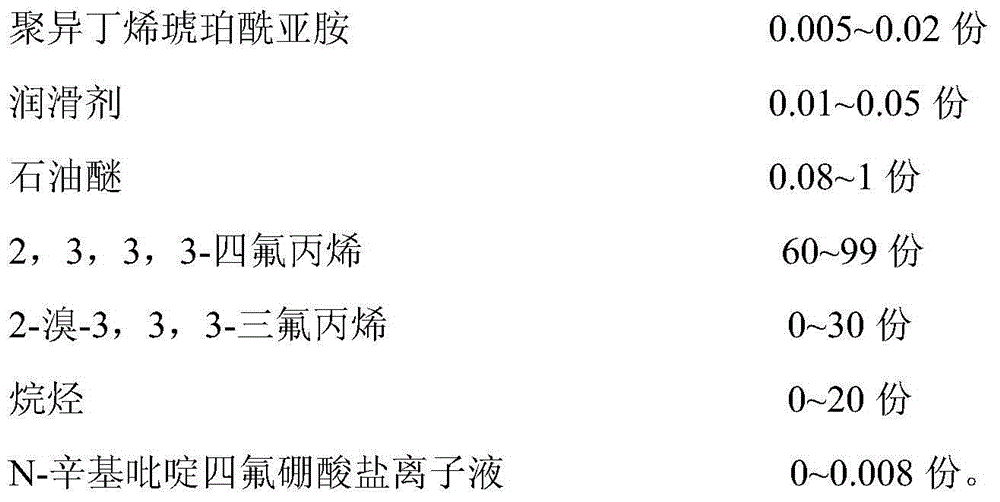

[0036] A kind of refrigerant that adds amide compatibilizer, by every 1Kg, its raw material formula is as follows:

[0037]

[0038] The preparation method is as follows:

[0039] The preparation of step (1) compatibilizer

[0040] According to the proportion, add 0.01 part of polyisobutylene succinimide, 0.025 part of polyalkylene glycol (PAG) lubricant, and 0.465 part of petroleum ether into a 500L reactor, and react at room temperature for 15 hours to obtain a compatibilizer.

[0041] Step (2) mixing

[0042] According to the proportion, the compatibilizer obtained in step (1) is mixed with 75 parts of 2,3,3,3-tetrafluoropropene (HFO1234yf), 15 parts of 2-bromo-3,3,3-trifluoropropene (BFO), Add 9.992 parts of isobutane (HC600a) and 0.008 parts of N-octylpyridine tetrafluoroborate ionic liquid into a 200L turbulent flow circulating kettle, and mix in the liquid state for 24 hours to obtain the product. The number is WN-1.

Embodiment 2

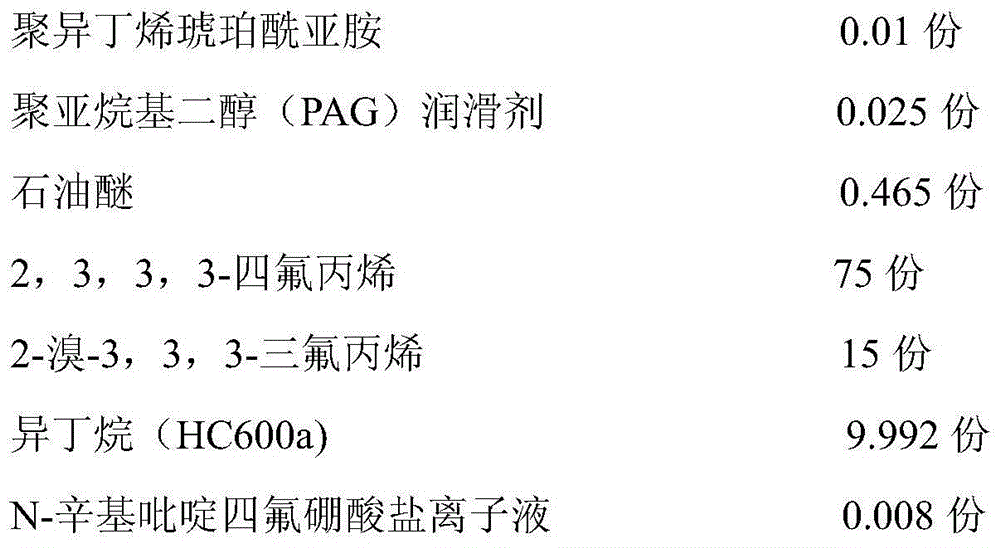

[0044] A kind of refrigerant that adds amide compatibilizer, by every 1Kg, its raw material formula is as follows:

[0045]

[0046] The preparation method is as follows:

[0047] The preparation of step (1) compatibilizer

[0048] According to the proportion, add 0.01 part of polyisobutylene succinimide, 0.01 part of polyol ester (POE-32) lubricant, and 0.98 part of petroleum ether into a 500L reactor, and react at room temperature for 20 hours to obtain a compatibilizer.

[0049] Step (2) mixing

[0050] According to the proportion, mix the compatibilizer obtained in step (1) with 60 parts of 2,3,3,3-tetrafluoropropene (HFO1234yf), 30 parts of 2-bromo-3,3,3-trifluoropropene (BFO), 8. Add 995 parts of n-butane and 0.005 parts of N-octylpyridine tetrafluoroborate ionic liquid into a 200L turbulent flow circulating kettle, and mix for 40 hours in the liquid state to obtain the product. The number is WN-2.

Embodiment 3

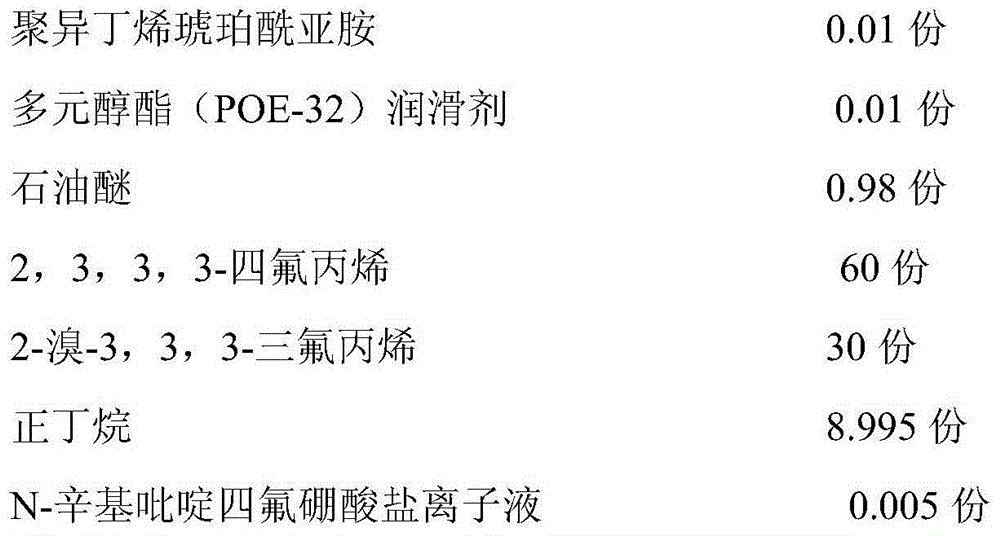

[0052] A kind of refrigerant that adds amide compatibilizer, by every 1Kg, its raw material formula is as follows:

[0053]

[0054] The preparation method is as follows:

[0055] The preparation of step (1) compatibilizer

[0056] Add 0.005 parts of polyisobutylene succinimide, 0.01 parts of polyalkylene glycol (PAG) lubricant, and 0.085 parts of petroleum ether into a 500L reactor, and react at room temperature for 10 hours to obtain a compatibilizer.

[0057] Step (2) mixing

[0058] According to the ratio, the compatibilizer obtained in step (1) will be mixed with 69.899 parts of 2,3,3,3-tetrafluoropropene (HFO1234yf), 10 parts of 2-bromo-3,3,3-trifluoropropene (BFO) , 20 parts of n-pentane, and 0.001 part of N-octylpyridine tetrafluoroborate ionic liquid were added to a 200L turbulent flow circulating kettle, and mixed for 10 hours in a liquid state to obtain the product. The number is WN-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com