Flat sewing machine for garment production

A sewing machine and flat car technology, applied in the direction of sewing machine components, sewing machine control devices, sewing equipment, etc., can solve the problems that the sewing machine does not have a hot pressing function, cannot flatten clothing fabrics, and is inconvenient to step on the pedal, so as to improve the range of blowing , Reduce work efficiency and reduce workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

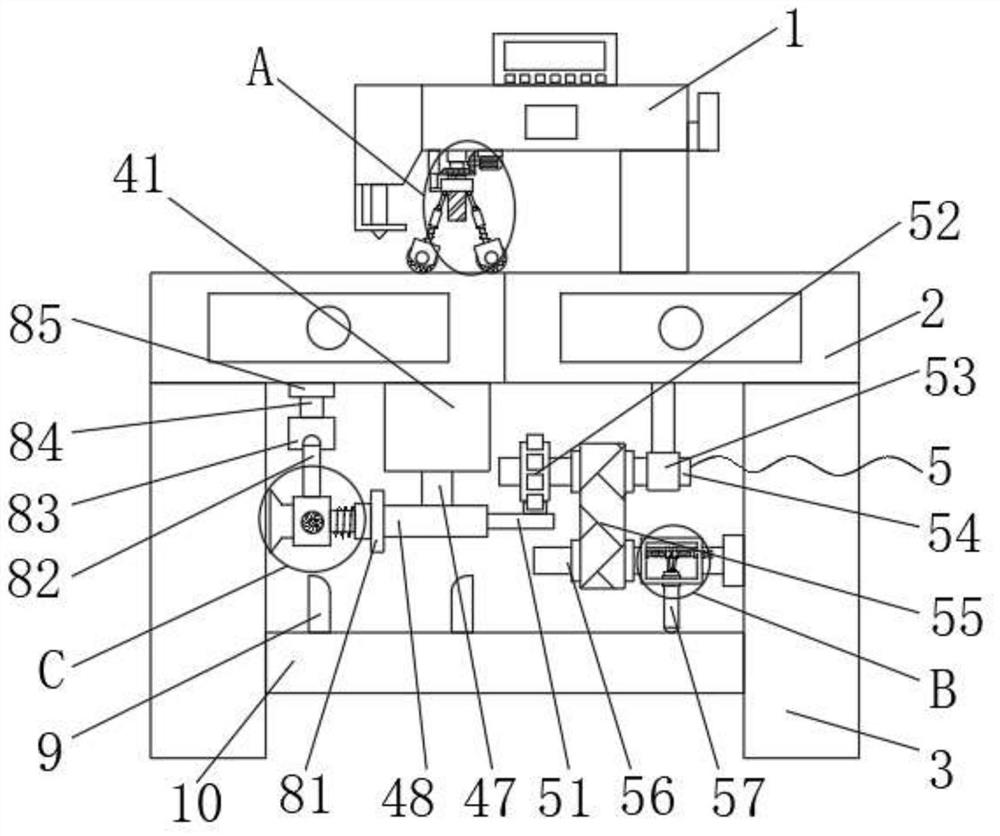

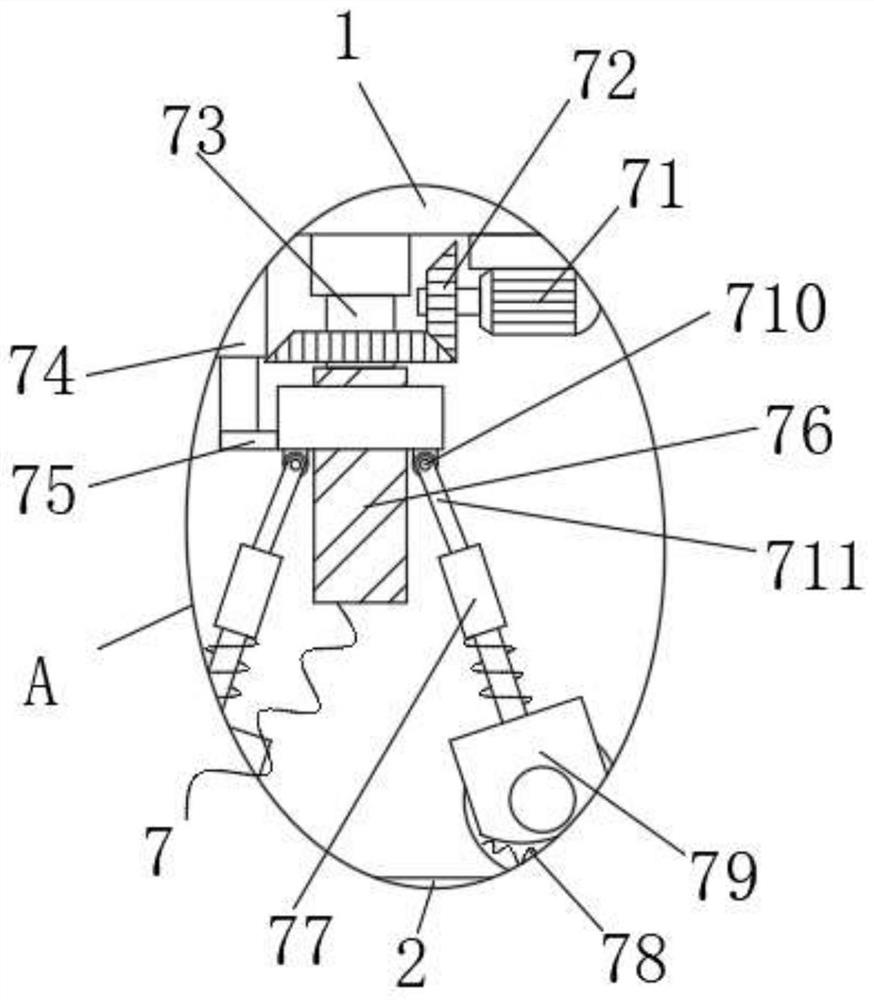

[0029] A flat car sewing machine for garment production, such as Figure 1-2As shown, it includes a placement cabinet 2, the upper surface of the placement cabinet 2 is fixedly connected with a sewing machine body 1, and the lower surface of the sewing machine body 1 is fixedly connected with a heat-pressing mechanism 7, and the heat-pressing mechanism 7 includes a second motor 71. The upper surface of the second motor 71 is fixedly connected with the rear side of the lower surface of the sewing machine body 1 through the second fixed seat, and the outer surface of the output shaft of the second motor 71 is clamped with the first bevel gear 72, and the outer surface of the first bevel gear 72 The second bevel gear is engaged with the second bevel gear, and the fifth rotating shaft 73 is clamped inside the second bevel gear. The bottom end of the fifth rotating shaft 73 is fixedly connected with the second reciprocating screw 76, and the outer surface of the second reciprocating...

Embodiment 2

[0032] A flat car sewing machine for garment production, which differs from Embodiment 1 in that, as figure 1 and Figure 4-6 As shown, the four corners of the lower surface of the storage cabinet 2 are fixedly connected with support columns 3, the lower surface of the storage cabinet 2 is fixedly connected with a moving mechanism 4, and the left side of the moving mechanism 4 is fixedly connected with a heat dissipation mechanism 8, The heat dissipation mechanism 8 includes an extension plate 81, the right side of the extension plate 81 is fixedly connected to the left end of the moving rod 48, the left side of the extension plate 81 is clamped with a sixth bearing, and the sixth bearing is sleeved with a sixth rotating shaft 89, the outer surface of the sixth rotating shaft 89 is covered with a torsion spring 88, and the two ends of the torsion spring 88 are respectively fixedly connected with the outer surface of the sixth rotating shaft 89 and the left side of the sixth be...

Embodiment 3

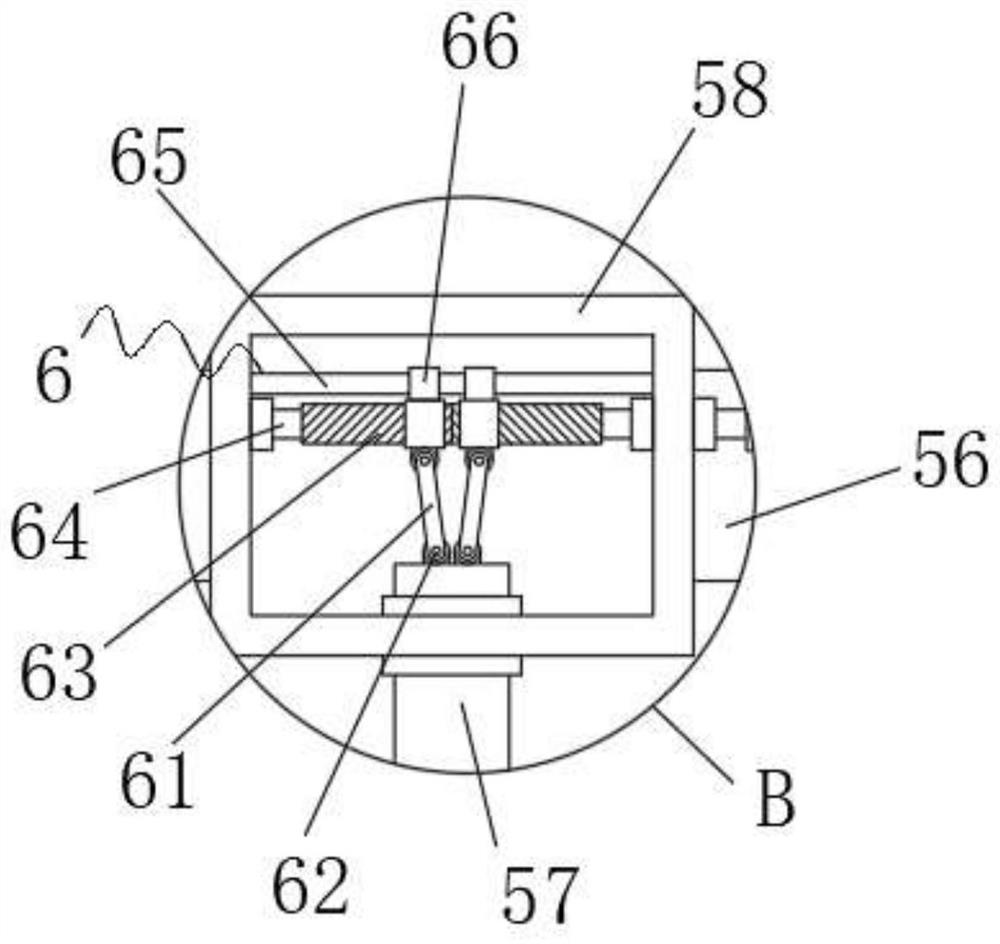

[0035] A flat car sewing machine for garment production, which differs from Embodiment 1 in that, as figure 1 and 3 As shown, the right side of the moving mechanism 4 is fixedly connected with a rotating mechanism 5, one side of the rotating mechanism 5 is fixedly connected with an adjusting mechanism 6, one side of the supporting column 3 is provided with a pedal 10, and the upper surface of the pedal 10 Two rectangular plates 9 are fixedly connected, and the moving mechanism 4 includes a housing 41 and a first motor 42;

[0036] Wherein, the back side of the housing 41 is fixedly connected with the first motor 42 through the first fixing base, the output shaft of the first motor 42 is fixedly connected with the first rotating shaft 46, and the outer surface of the first rotating shaft 46 is clamped with the first reciprocating Lead screw 45, the outer surface of the first reciprocating lead screw 45 is threadedly connected with a lead screw seat, the upper surface of the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com