Two-wheeled vehicle line control braking structure

A brake-by-wire, two-wheeled vehicle technology, applied in the direction of brake actuators, bicycle brakes, brake types, etc., can solve the problems of taking up too much space, unable to monitor the braking status in real time and various braking methods, etc. The effect of small structure size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

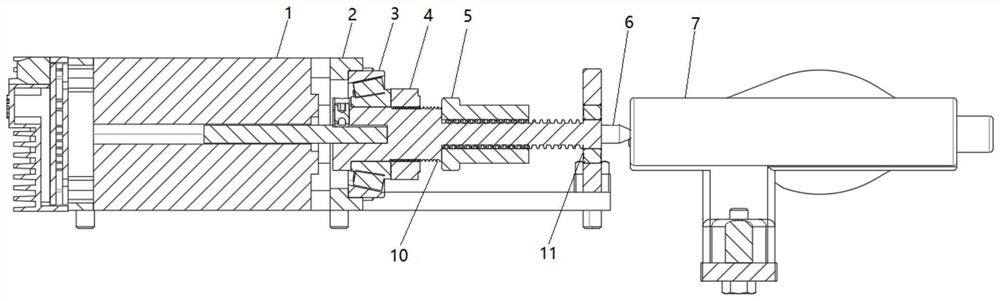

[0020] In order to make the content of the present invention clearer and easier to understand, the content of the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

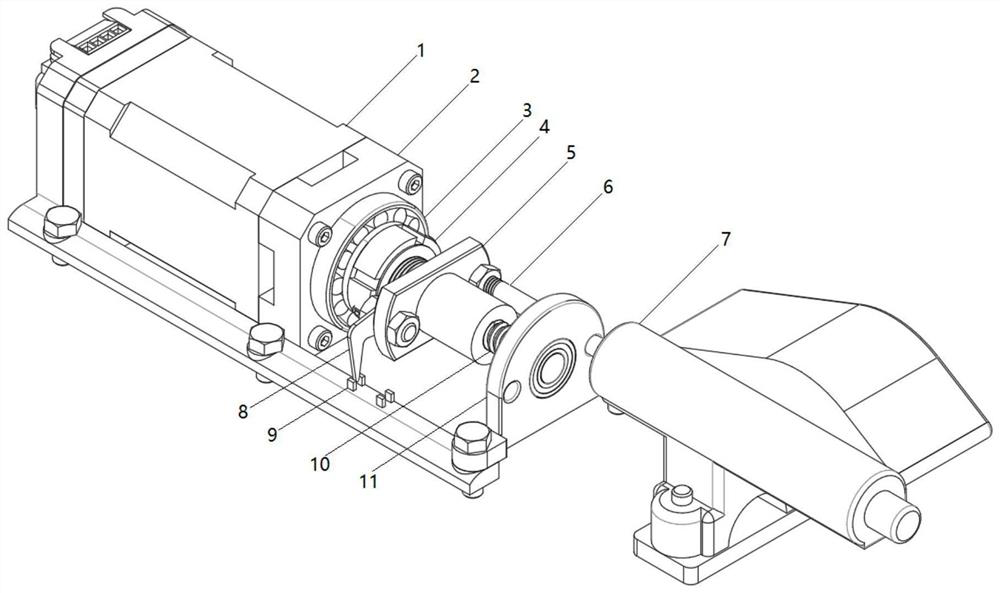

[0021] figure 1 It schematically shows the overall schematic diagram of the brake-by-wire structure of the two-wheeled vehicle according to the preferred embodiment of the present invention.

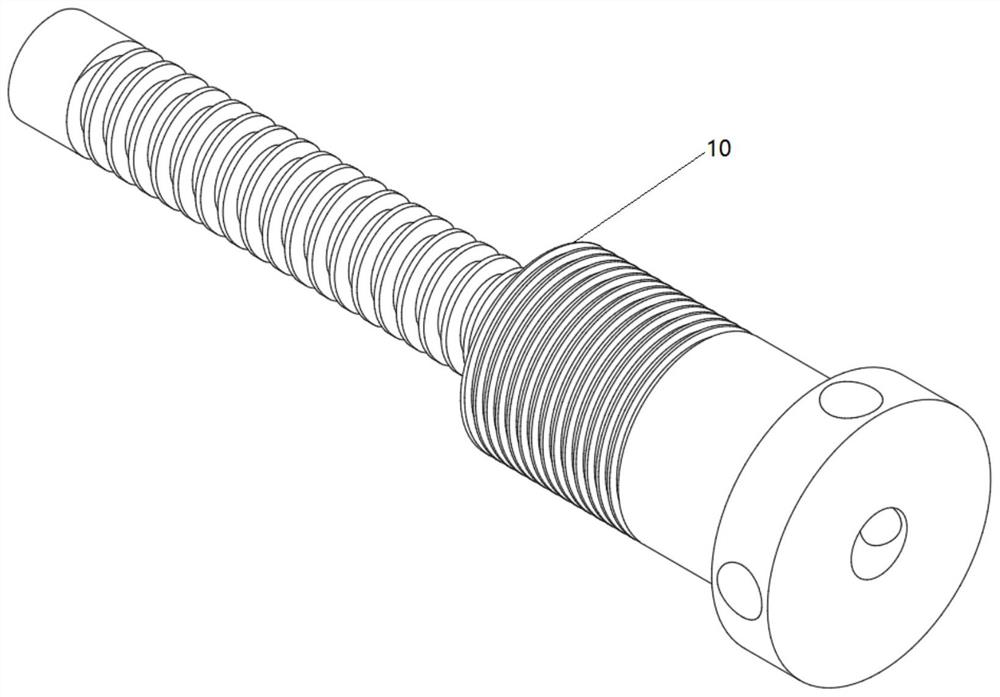

[0022] The brake-by-wire structure of a two-wheeled vehicle according to a preferred embodiment of the present invention includes: a motor 1, a fixed support 2, a tapered roller bearing 3, a lock nut 4, a screw nut 5, an upper pump push rod 6, and a brake upper pump 7 , sensor probe 8, photoelectric limit sensor 9, trapezoidal screw 10 and bearing 11 with ball bearing.

[0023] More specifically, see Figure 1-Figure 4 , The motor 1 and the ball bearing support 11 are connected to the fixed support 2 (for example, by bolts).

[0024] The trapezoidal scr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap