Intersecting-spherical-shell pressure vessel with partition plates

A technology of pressure vessels and spherical shells, which is applied in the field of pressure vessels and can solve the problems of low structural efficiency of special-shaped vessels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

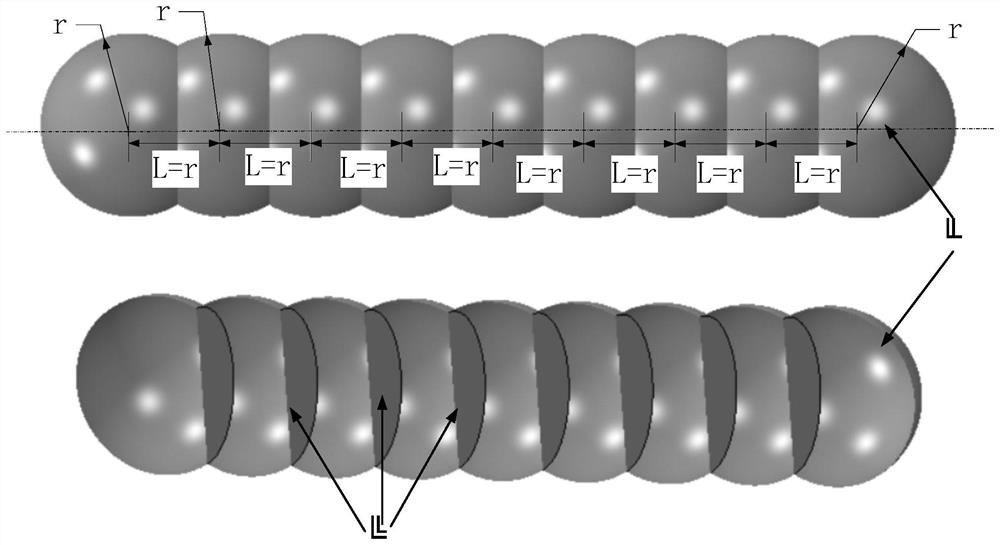

[0041] Embodiment 1: A kind of intersecting spherical shell pressure vessel with partition for road transportation, comprising:

[0042] 1) The design internal pressure of the pressure vessel is 4.1MPa, the material used is steel Q235, the yield stress is 235MPa, and the density is 7900kg / m 3 , it is required that the maximum stress under the design internal pressure is not higher than the yield stress of the material, the maximum diameter is 2.5m, and the volume is not less than 53m 3 ;

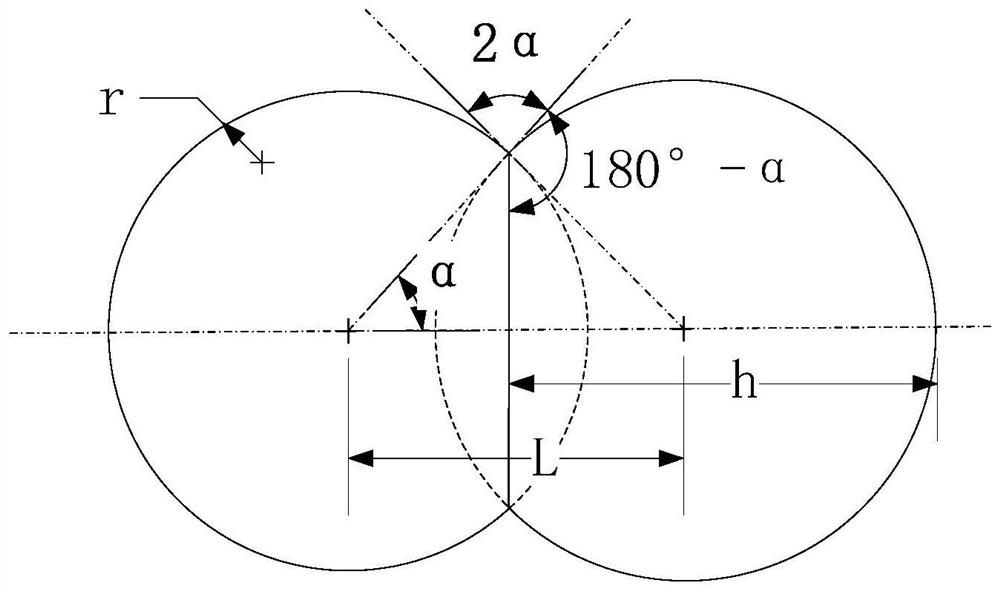

[0043] 2) The present embodiment is composed of 9 spherical shells with a diameter of 2.5 meters intersecting, and welding connections are adopted between the spherical shells and between the spherical shells and the partition, and the distance between the centers of the 9 spherical shells is 1.25m;

[0044] 3) According to the strength requirements of the pressure vessel, the thickness of the spherical shell is 10.9mm (this example is calculated according to the ideal thickness, without co...

Embodiment 2

[0050] Embodiment 2: attached Figure 4 It is an annular intersecting pressure vessel with partitions designed based on the present invention, which is suitable for setting pressure vessels in annular narrow height spaces (such as artificial satellites and space stations);

Embodiment 3

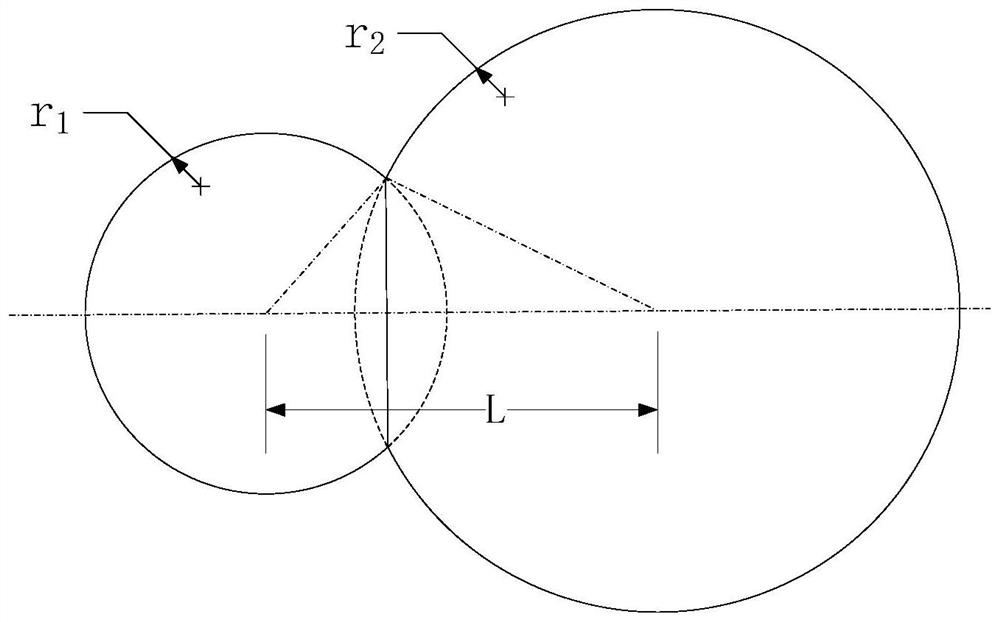

[0051] Embodiment 3: Attach Figure 5 It is a pressure vessel formed by intersecting spherical shells of different specifications based on the present invention, wherein 4 large-sized spherical shells intersect to form a nearly cylindrical shell shape, 10 small-diameter spherical shells intersect with the bottom large-diameter spherical shell, and 10 small-diameter spherical shells intersect The lower bottom of the shell is the same height as that of the large spherical shell at the bottom, and the small-diameter spherical shell and its partitions also serve as the supporting legs of the large spherical shell, which is convenient for the overall installation and fixing of the pressure vessel on the ground. The entire pressure vessel has a compact structure and high space utilization, and the structural efficiency equivalent to that of an ideal spherical shell pressure vessel can be obtained after reasonable design of the thickness of each spherical shell.

[0052] Embodiment 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield stress | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com