Diesel engine DPF system rapid aging test method and system, medium and application

A rapid aging and DPF technology, which is used in internal combustion engine testing, mechanical component testing, and machine/structural component testing. and filtration efficiency, shortening the development and evaluation cycle, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

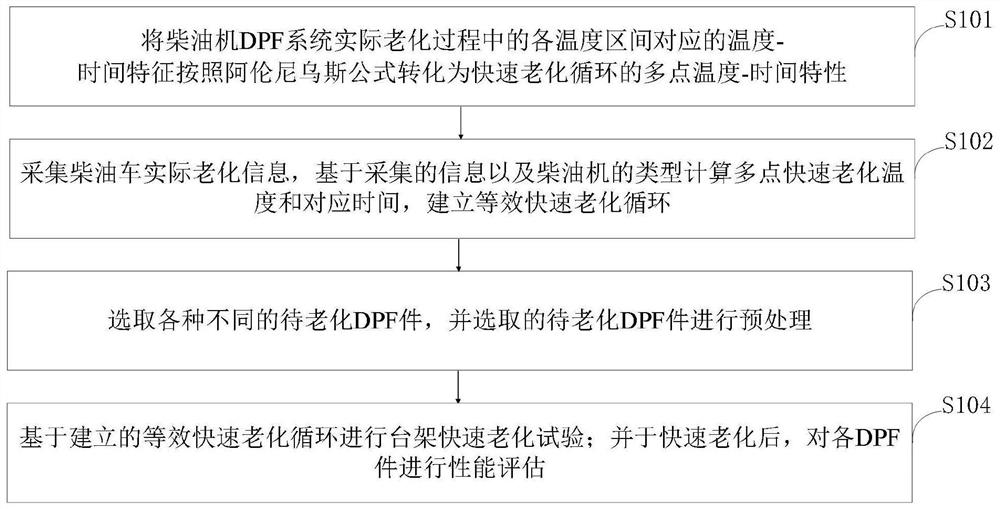

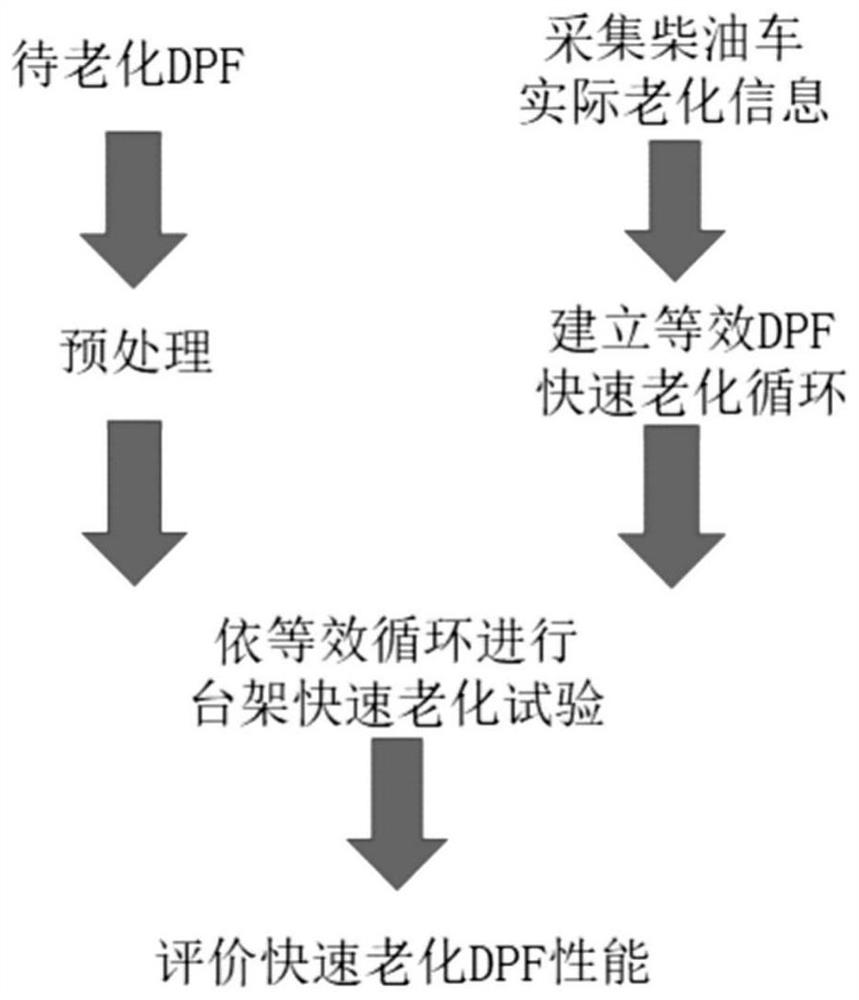

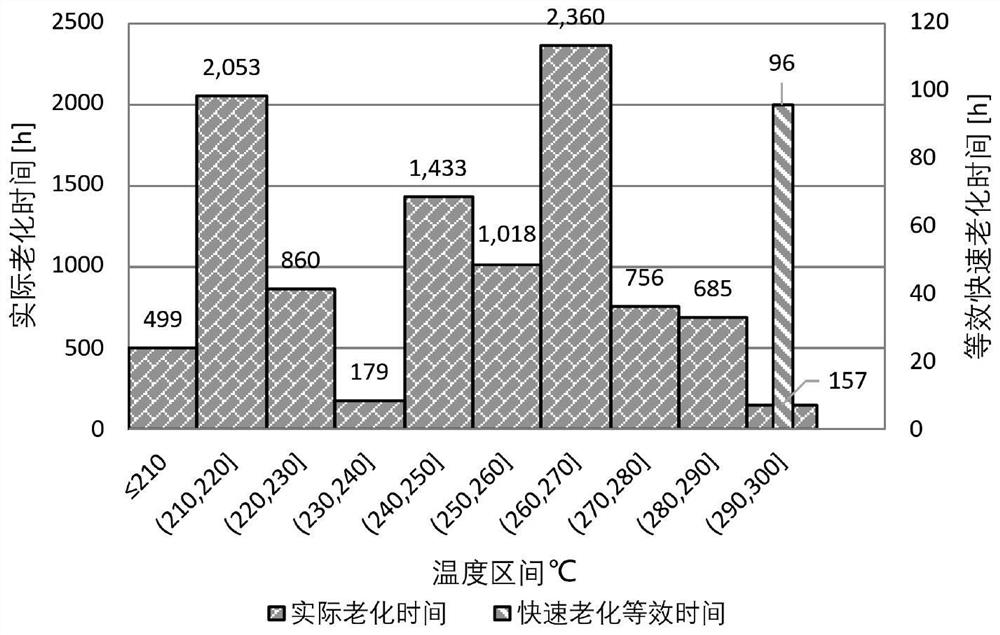

Method used

Image

Examples

Embodiment 1

[0072] 1. DPF rapid aging theory

[0073] Catalytic DPF (Catalytic DPF, CDPF) is a kind of DPF that uses catalytic regeneration as its regeneration principle. At present, CDPF technology has become the main device for diesel engine to control exhaust particles. Based on the device characteristics of CDPF, its thermal aging speed can be accelerated by increasing its working temperature. However, due to the large differences in the use scenarios and technologies of various CDPFs, the rapid aging methods are complicated, and the test conditions vary greatly, so there is a lack of CDPF aging test methods that can be evaluated uniformly. Starting from this point of view, the present invention studies the regeneration and aging mechanism of DPF, and finds a rapid aging method that is universally applicable to all CDPFs, which can complete the aging of CDPF conveniently and efficiently, and provides a basis for the research and development and evaluation of diesel vehicle emission s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com