Silicone rubber material quality evaluation method based on TGA-FTIR

A quality evaluation and silicone rubber technology, applied in the field of silicone rubber material performance research, can solve the problems of long time consumption, poor equivalence of natural operating environment, heavy maintenance workload of personnel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0064] (1) Sample preparation, cut samples from the cured silicone rubber material and its base rubber;

[0065] Select two types of composite insulators produced by a certain manufacturer, and use a wallpaper knife to cut a piece at the shed of the shed as a test silicone rubber sampleN 硅橡胶 , respectively recorded as 3#, 4#. 3# and 4# are silicone rubber materials with different proportions made of the same base rubber and filler. The sample weight was 20±3 mg. Use a wallpaper knife to cut out the base rubber used in the silicone rubber material as a test base rubber sample N 基胶 ; 3#, 4# two samples are similar in shape and structure, and the surface dirt is wiped with absolute ethanol, placed in a dust cover, and dried naturally.

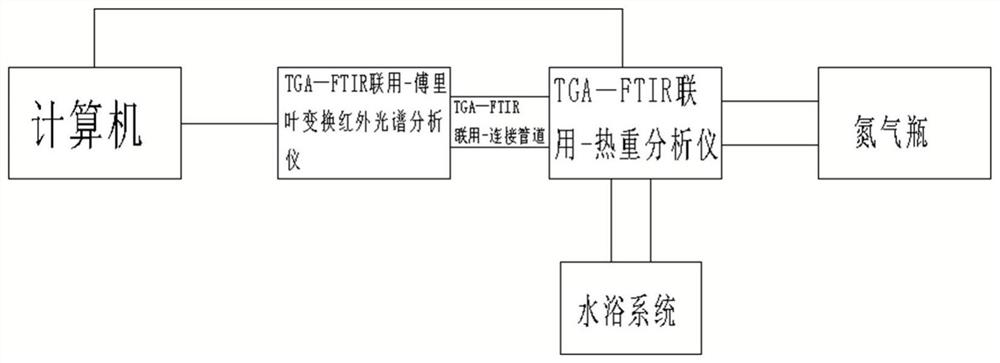

[0066] (2) The gas measurement unit of the FTIR experimental instrument is connected with the test unit of the TGA experimental instrument, and the test parameters are set.

[0067] The gas measurement unit of the FTIR experimental instrument ...

Embodiment 3

[0087] (1) Sample preparation, cut samples from the cured silicone rubber material and its base rubber;

[0088] Select two types of composite insulators produced by a certain manufacturer, and use a wallpaper knife to cut a piece at the shed of the shed as a test silicone rubber sampleN 硅橡胶 , respectively recorded as 5#, 6#. 5# and 6# are silicone rubber materials with different proportions made of the same base rubber and filler. The sample weight was 20±3 mg. Use a wallpaper knife to cut out the base rubber used in the silicone rubber material as a test base rubber sample N 基胶 ; 5#, 6# two samples are similar in shape and structure, and the surface dirt is wiped with absolute ethanol, placed in a dust cover, and naturally air-dried.

[0089] (2) The gas measurement unit of the FTIR experimental instrument is connected with the TGA test unit, and the test parameters are set.

[0090] The gas measurement unit of the FTIR experimental instrument is connected with the TGA t...

Embodiment 4

[0110] (1) Sample preparation, cut samples from the cured silicone rubber material and its base rubber;

[0111] Select two types of composite insulators produced by a certain manufacturer, and use a wallpaper knife to cut a piece at the shed of the shed as a test silicone rubber sampleN 硅橡胶 , respectively recorded as 7#, 8#. 7# and 8# are silicone rubber materials with different proportions made of the same base rubber and filler. The sample weight was 20±3 mg. Use a wallpaper knife to cut out the base rubber used in the silicone rubber material as a test base rubber sample N 基胶 ; 7#, 8# two samples are similar in shape and structure, and the surface dirt is wiped with absolute ethanol, placed in a dust cover, and naturally air-dried.

[0112] (2) The gas measurement unit of the FTIR experimental instrument is connected with the TGA experimental instrument, and the test parameters are set.

[0113] The gas measurement unit of the FTIR experimental instrument is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com