Permanent magnet capable of axially adjusting uniform field

An axial adjustment, permanent magnet technology, applied in the direction of magnets, magnetic objects, permanent magnets, etc., can solve the problems of low field strength, increase in height, increase the volume of permanent magnets, etc., to reduce weight and cost, prevent excessive compensation, Compensate for the effect of end effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1, as a comparative example, the original height of the magnetic block of each layer magnetic ring is set to be 10mm in this embodiment, and the magnetic field intensity B 0 =1023.8mT, the uniformity is 8612ppm. Then the height of all the magnetic blocks in the ninth layer magnetic ring L1, the eighth layer magnetic ring L2, the second layer magnetic ring L8, and the first layer magnetic ring L9 are raised to 14mm, and the uniformity of the permanent magnet is 5259ppm. After the height of all the magnetic blocks in the seven-layer magnetic ring L3 and the third-layer magnetic ring L7 are increased to 14mm, the uniformity of the permanent magnet is 5899ppm, but there is an overcompensation for the uniformity.

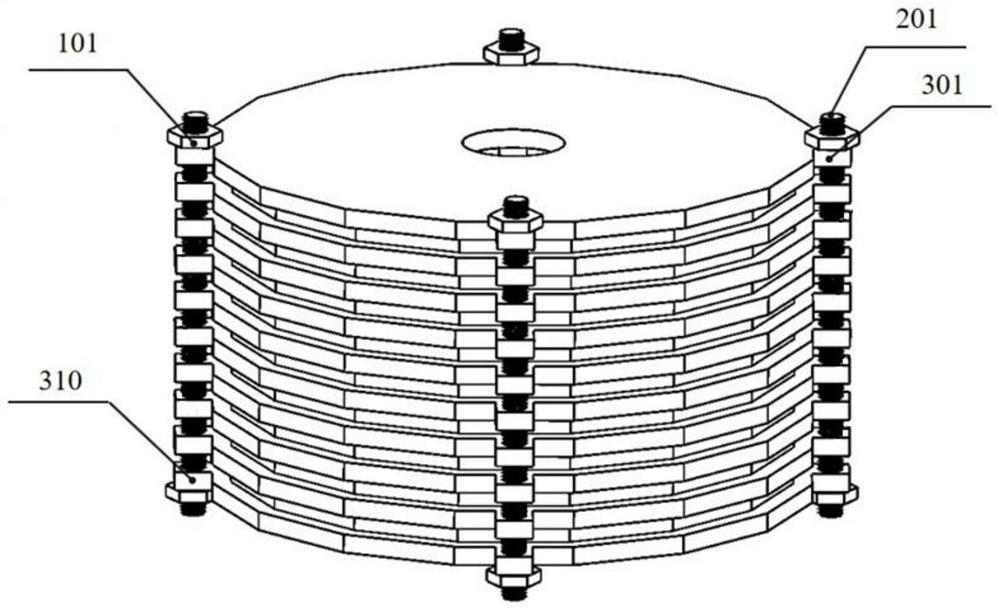

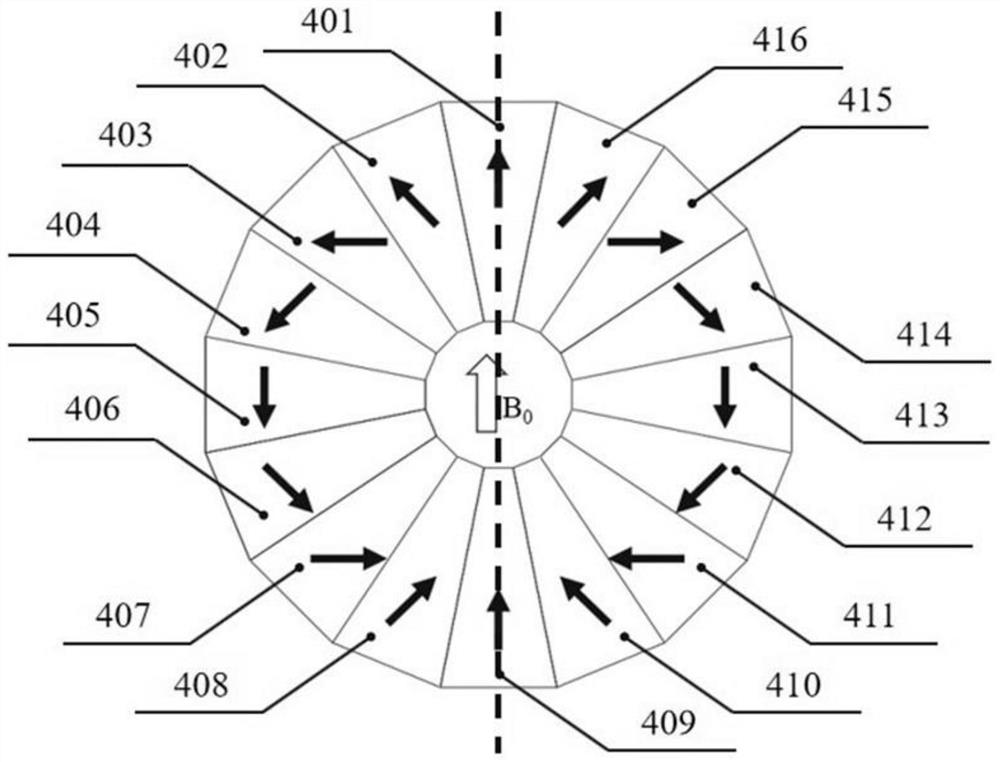

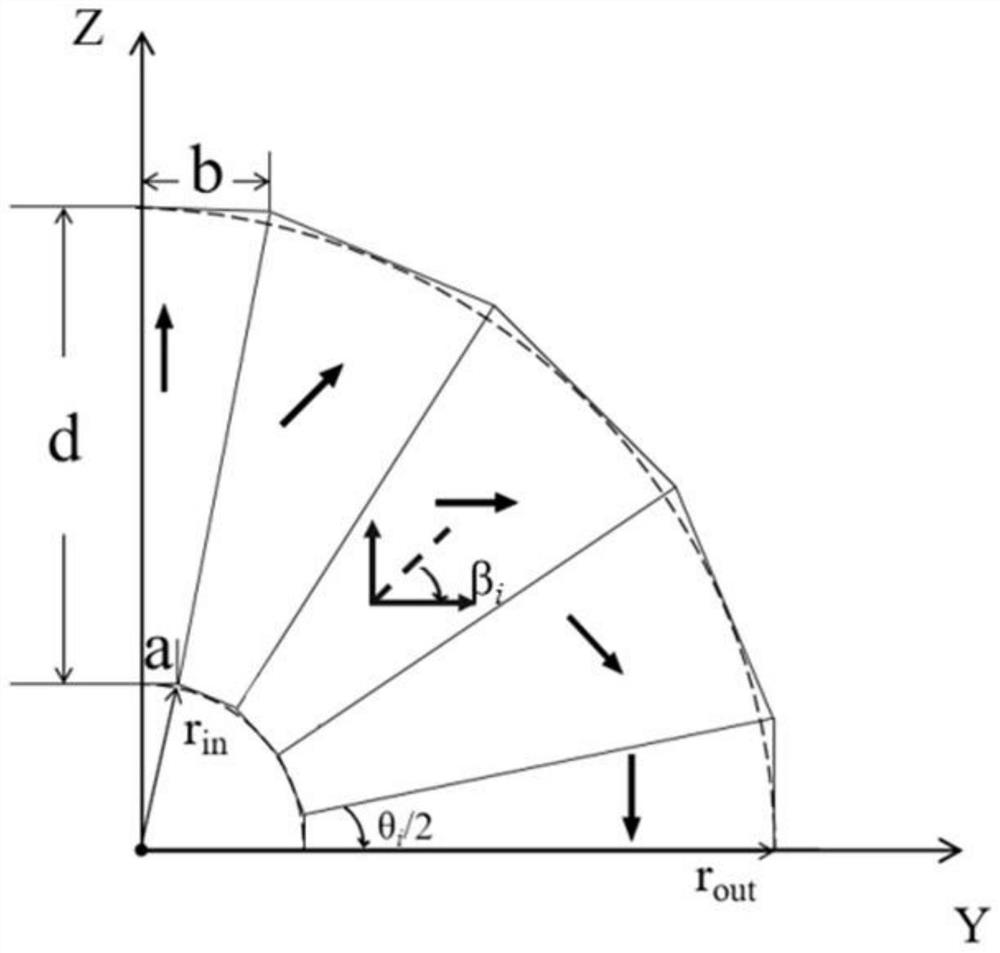

[0029] see Figure 1~5 , Example 2, such as figure 1 As shown, the present embodiment is a permanent magnet for axially adjusting a uniform field, which includes a base plate and a magnetic ring, the base plate is ring-shaped, and the number of layers...

Embodiment 2

[0054] Comparing Embodiment 2 with Embodiment 1, with respect to the ninth-layer magnetic ring L1, the eighth-layer magnetic ring L2, the seventh-layer magnetic ring L3, the third-layer magnetic ring L7, and the second-layer magnetic ring of Embodiment 1, The method of raising the height of all magnetic blocks in the ring L8 and the first layer magnetic ring L9 improves the uniformity by 31.5%; this embodiment improves the uniformity by 88.5%, and compared with the ninth layer magnetic ring L1 and the eighth layer The method of increasing the height of all magnetic blocks in the magnetic ring L2, the seventh magnetic ring L3, the third magnetic ring L7, the second magnetic ring L8, and the first magnetic ring L9 uses 50.2% less material.

[0055] The number of magnetic ring layers in this embodiment 2 is N=9, the number of magnetic blocks in each magnetic ring is M=16, the structure size is Φ142×240 mm, the structure is hollow inside, and the middle aperture is Φ60 mm. Compare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com