Compressor motor rotor structure capable of improving heat dissipation effect and heat dissipation method

A technology of motor rotor and heat dissipation effect, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit rotating parts, etc., can solve problems such as weak heat dissipation effect, demagnetization of permanent magnets, and the risk of demagnetization of accelerated magnetic steel 10, so as to reduce The effect of high temperature demagnetization risk, reduction of flux leakage, and improvement of motor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

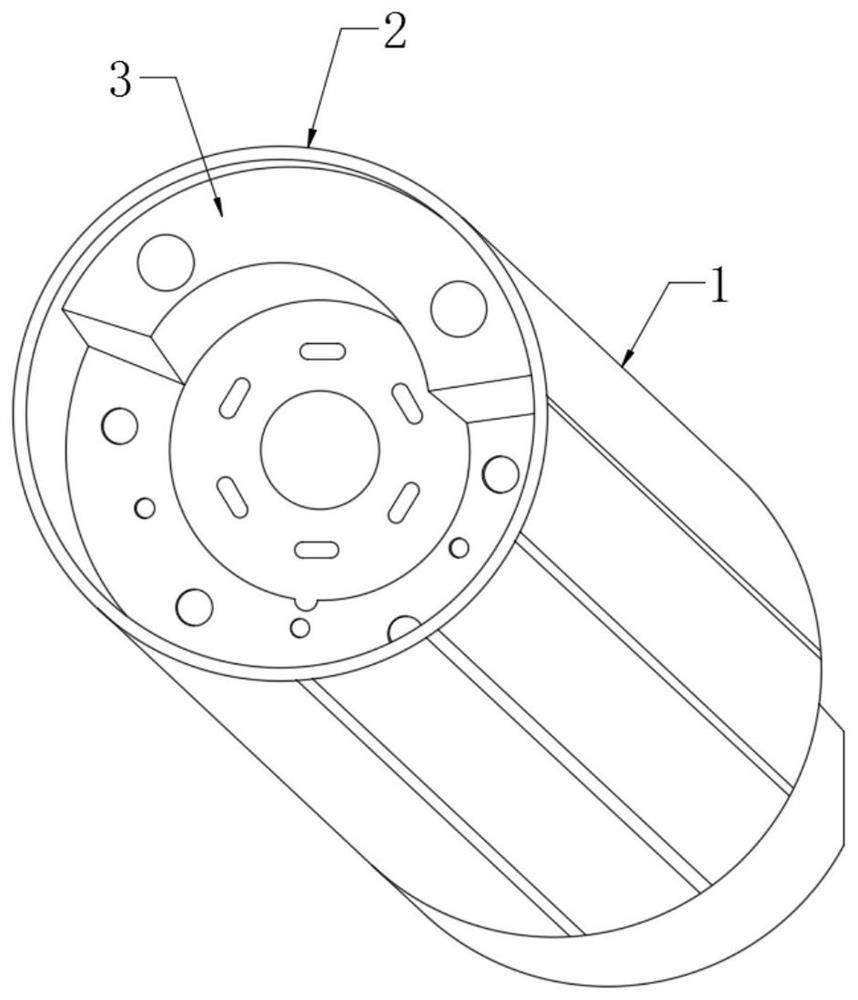

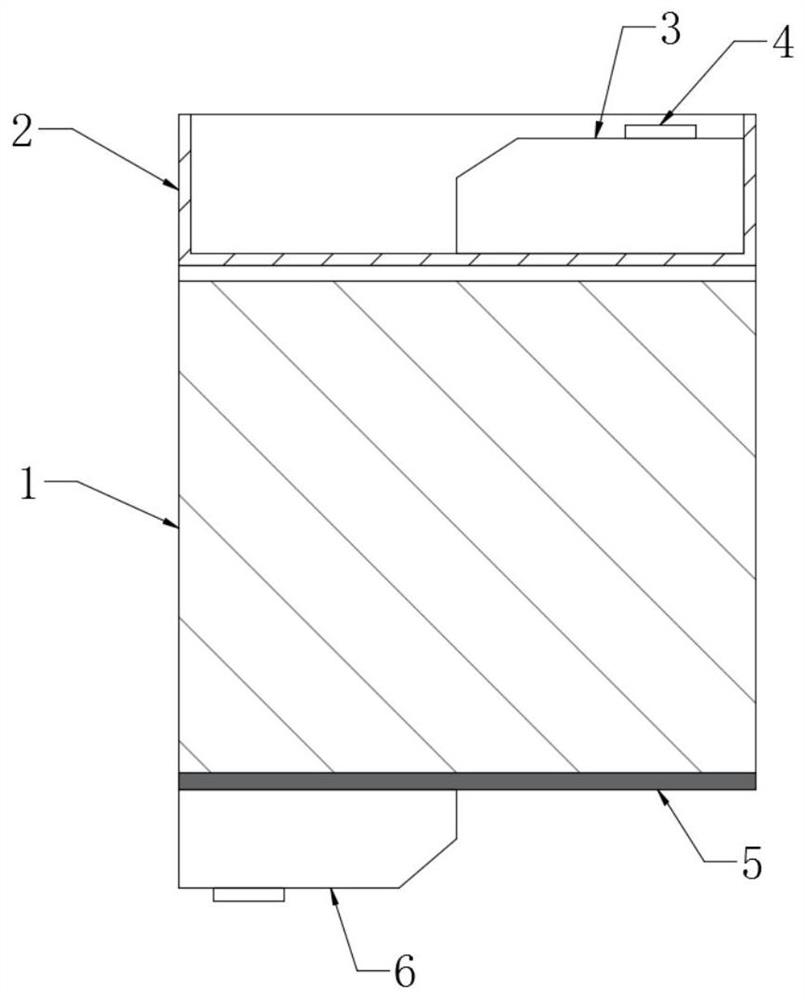

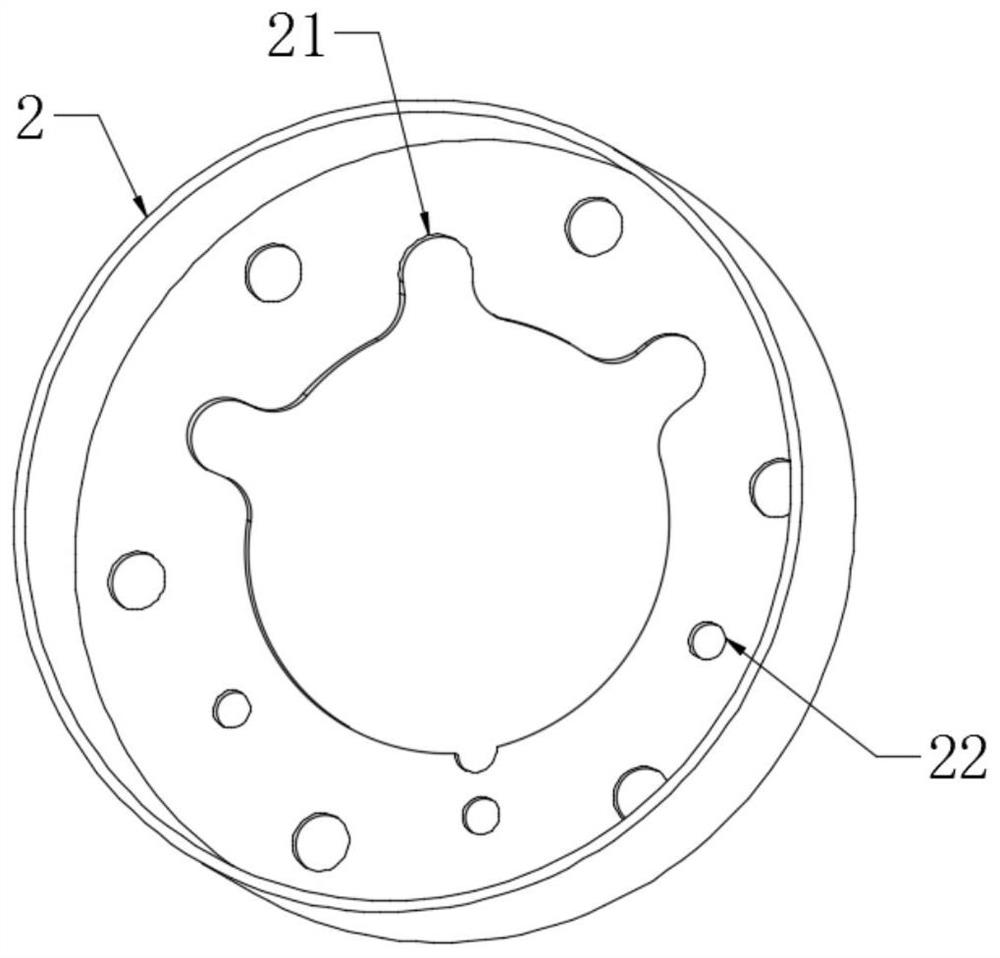

[0035] see Figure 1-Figure 8 , the present invention provides a technical solution: a compressor motor rotor structure and heat dissipation method for improving heat dissipation, including a rotor core 1, an oil baffle 2 and a baffle 5, and the oil baffle 2 is arranged on the rotor core 1 At one end, the baffle plate 5 is arranged on the other end of the rotor core 1, and a plurality of V-shaped magnetic steels 12 are arranged at equal intervals on the rotor core 1, and flow grooves 11 are opened between adjacent V-shaped magnetic steels 12 to solve the problem of It solves the problem that the heat dissipation of the magnetic steel part of the rotor of the compressor motor in the past is not sufficient and reasonable.

[0036] Specific heat dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com