A high-efficiency corn cob device

A high-efficiency technology for corn crushing, used in threshing equipment, agriculture, applications, etc., can solve the problems of unable to guarantee stable core crushing and conveying, relying on spring consistency, unable to guarantee simultaneous clamping and positioning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

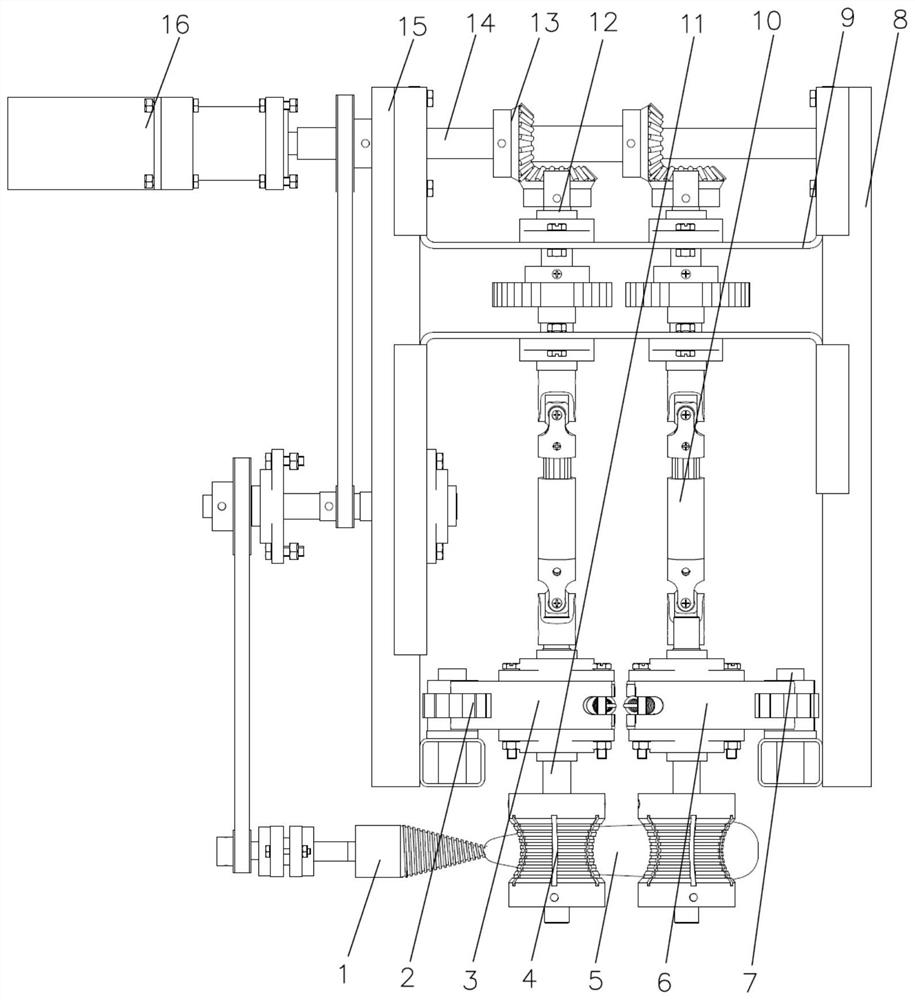

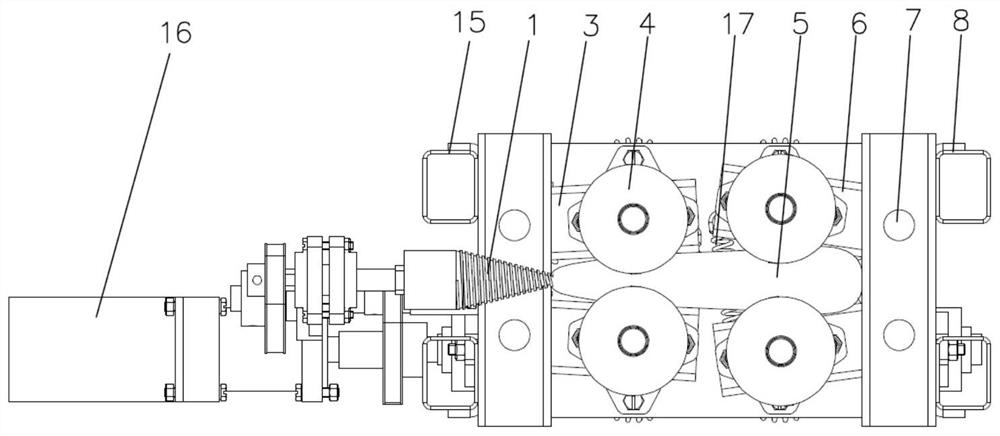

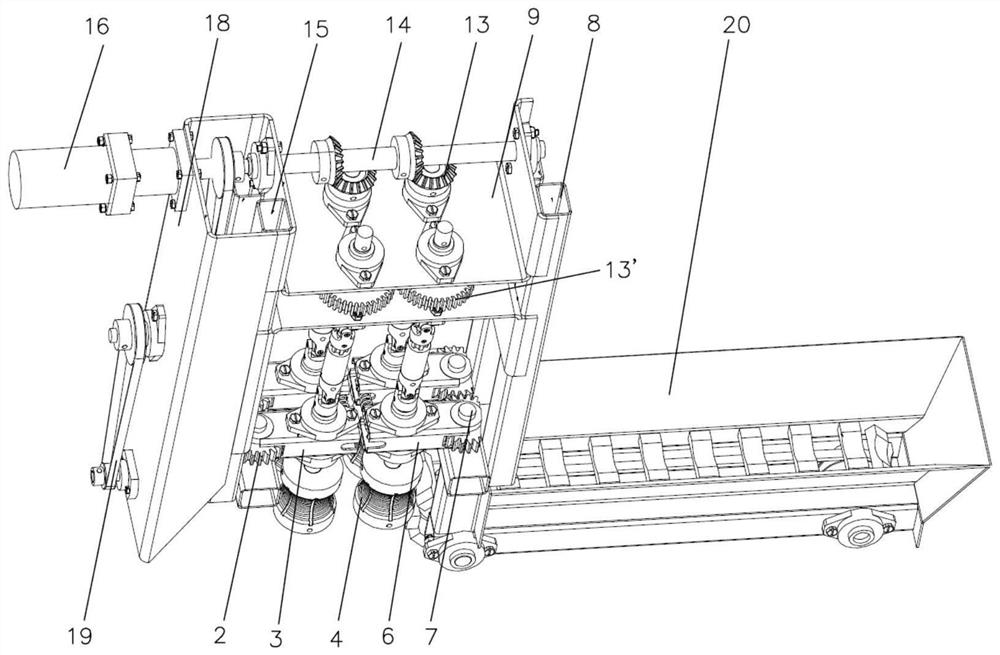

[0025] The high-efficiency corn cob device of the present embodiment is as Figure 1 to Figure 4 Shown, comprise front and rear struts 15,8 that are fixedly connected with the frame, the bottom of front and rear struts 15,8 are respectively hinged by vertical pin 7 and stretch forward left and right hinged plates 6 and stretch left and right. The right hinged plate 3, the hinges of the forward left and right hinged plates 6 and the rearward stretched left and right hinged plates 3 are respectively fixedly connected with the corresponding synchronous meshing gears 2, and the forward left and right hinged plates 6 and the rear The cantilever ends of the left and right hinged plates 3 are respectively connected with the corresponding extension springs 17, so there is a tendency to move closer to each other. Each hinge plate 3 , 6 respectively supports the saddle roller 4 driven by the driving shaft 14 through the universal joint 10 . Specifically, the horizontal drive shaft 14 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com