Dust removal equipment for concrete productionand dust removal method

A technology of dust removal equipment and concrete, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, etc., can solve problems such as worker hazards, air dust exceeding the standard, etc., to improve cleanliness, improve air freshness, and improve use the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

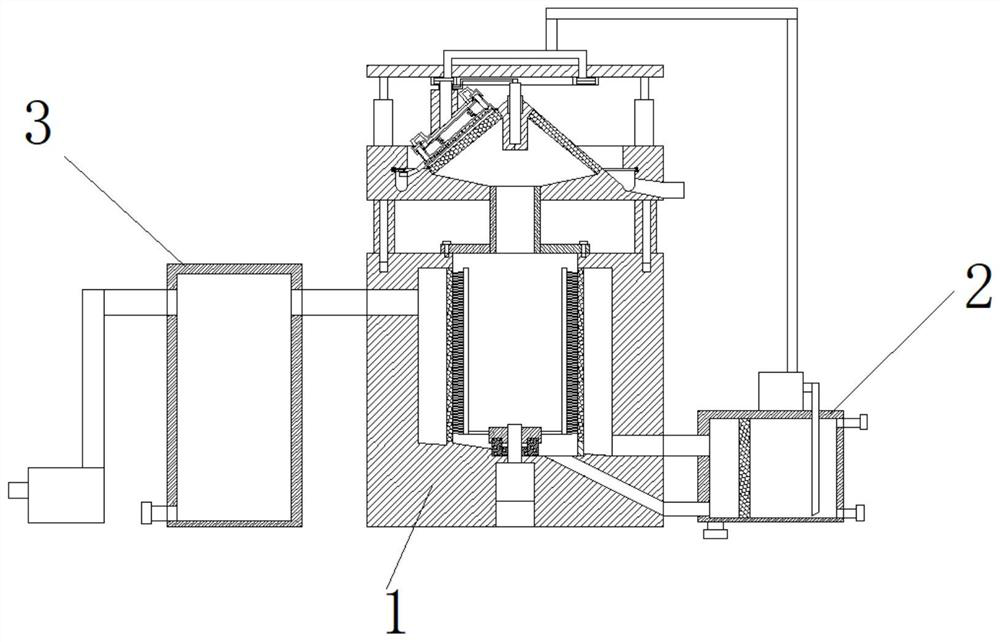

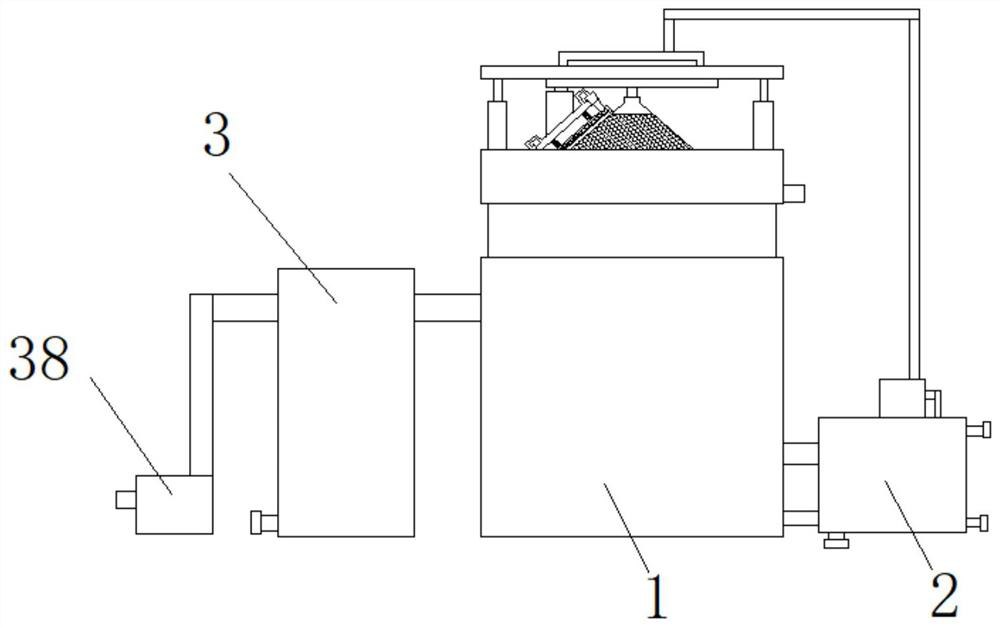

[0038] A dust removal device for concrete production, including a filter mechanism 1, a water tank 2 and a buffer tank 3;

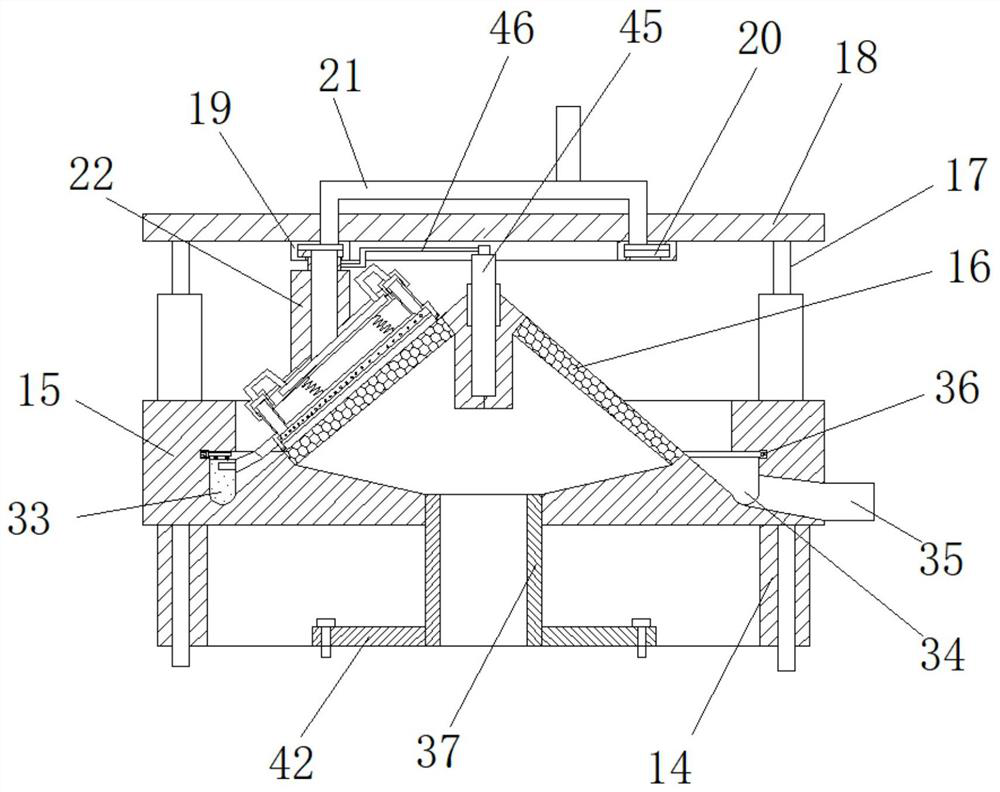

[0039] Described filtering mechanism 1 comprises box body 4, and the top of described box body 4 is provided with cylindrical cavity 5 and annular cavity 6, and described cylindrical cavity 5 is positioned at the middle part of annular cavity 6, and described annular cavity 6 is provided with an annular filter screen 7, the top of the box 4 is fixed with a cylinder 14, the top of the cylinder 14 is connected with a tank 15, and the tank 15 is provided with a conical filter screen 16, so An annular groove 34 is provided around the bottom of the tapered filter screen 16 in the groove body 15, and the outer side of the groove body 15 is provided with a discharge pipe 35 communicating with the annular groove 34, and the bottom of the groove body 15 is located at The bottom of the conical filter screen 16 is connected with a gas pipe 37, the bottom of the gas ...

Embodiment 2

[0057] A dust removal method for dust removal equipment for concrete production, comprising the following steps:

[0058] S1. Place the filter mechanism 1 in the concrete production workshop for layout at intervals of 16 meters, and inject two-thirds of the water level into the transparent water tank 2 through the water adding pipe 43;

[0059] S2, extract the gas in the buffer tank 3 through the air pump 38, and the buffer tank 3 extracts the gas in the annular cavity 6 through the exhaust pipe 13, so that the air in the production workshop is filtered by the conical filter screen 16 and sucked into the cylindrical cavity The inside of the body 5 is filtered through the annular filter screen 7 again, and the air in the cylindrical cavity 5 is sucked into the air pump 38 through the annular cavity 6, the air extraction pipe 13 and the buffer tank 3 in sequence and discharged outward, so that the air in the production workshop The air is filtered out of dust;

[0060] S3, star...

Embodiment 3

[0063] A dust removal method for dust removal equipment for concrete production, comprising the following steps:

[0064] S1. Place the filter mechanism 1 in the concrete production workshop for layout at intervals of 7 meters, and inject two-thirds of the water level into the transparent water tank 2 through the water adding pipe 43;

[0065] S2, extract the gas in the buffer tank 3 through the air pump 38, and the buffer tank 3 extracts the gas in the annular cavity 6 through the exhaust pipe 13, so that the air in the production workshop is filtered by the conical filter screen 16 and sucked into the cylindrical cavity The inside of the body 5 is filtered through the annular filter screen 7 again, and the air in the cylindrical cavity 5 is sucked into the air pump 38 through the annular cavity 6, the air extraction pipe 13 and the buffer tank 3 in sequence and discharged outward, so that the air in the production workshop The air is filtered out of dust;

[0066] S3, start...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com