Workpiece shape correcting method and workpiece shape correcting device

A technology for shape correction and workpiece, applied in the field of workpiece shape correction method and workpiece shape correction device, can solve the problems of shape correction processing of metal processing parts, easily damaged hub, and no measurement, so as to improve shape correction accuracy, avoid damage, The effect of improving accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

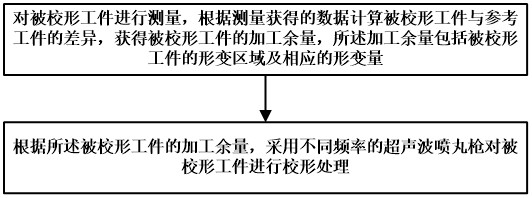

Method used

Image

Examples

Embodiment 1

[0070] When the workpiece to be calibrated is a metal plate to be processed, the measurement mechanism includes a first-line laser, a measurement manipulator and a measurement control module. The measurement manipulator is connected to the first-line laser, and the first-line laser and the measurement manipulator are further connected to the measurement control module. , the first-line laser is used to measure the metal plate to be processed, the measuring manipulator is used to drive the first-line laser to move, the measurement control module is used to control the movement of the measuring manipulator and calculate the metal plate to be processed according to the data obtained by the first-line laser measurement The difference between the piece and the reference sheet metal piece is used to obtain the machining allowance of the sheet metal piece to be processed. During implementation, the metal sheet to be processed is placed on the workbench, and the measurement control mod...

Embodiment 2

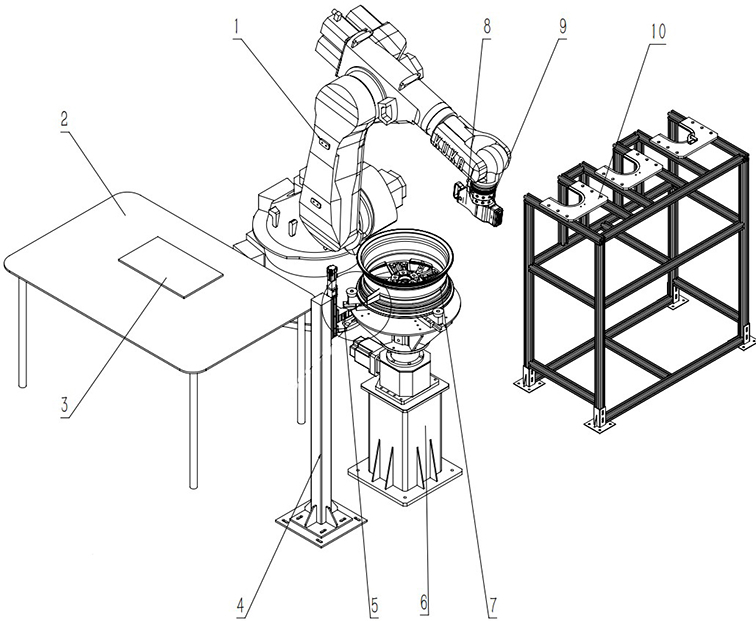

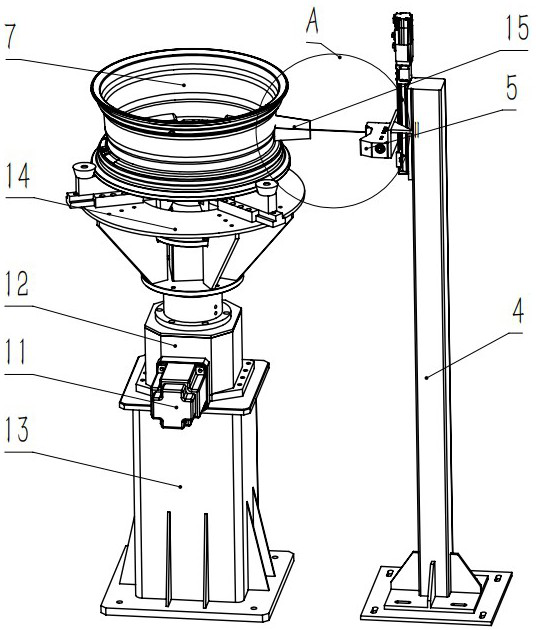

[0074] like figure 2 As shown, when the workpiece to be corrected is the hub to be corrected, the measuring mechanism includes a clamping and rotating device 6, a second line laser 5 and a measurement control module (not shown in the figure), wherein the clamping and rotating device is used to clamp the Calibrate the wheel hub and drive the wheel hub to be calibrated to rotate. The second line laser is used to measure the wheel hub to be calibrated. The measurement control module is connected with the clamping and rotating device and the second line laser, and is used to control the rotation of the clamping and rotating device and obtain according to the measurement. Calculate the difference between the hub to be calibrated and the reference hub based on the data, and obtain the machining allowance of the hub to be calibrated. During implementation, the wheel hub to be corrected is placed on the clamping and rotating device, and the measurement control module controls the rot...

Embodiment 3

[0080] combine Figure 2~Figure 4 As shown, when the workpiece to be corrected is the metal plate 3 to be processed and the hub 7 to be corrected, the measuring mechanism includes a first line laser (not shown in the figure), a second line laser 5, a clamping and rotating device, a measuring manipulator and A measurement control module, wherein the first line laser is connected to the measurement control module for measuring the metal sheet 3 to be processed, and the second line laser 5 is connected to the measurement control module for measurement of the wheel hub 7 to be corrected, clamping and rotating The device is connected to the measurement control module for clamping the wheel hub 7 to be calibrated and driving the wheel hub 7 to rotate. The measuring manipulator is connected to the first-line laser and the measurement control module for driving the first-line laser to move. The measurement control module It is used to control the measuring manipulator to control the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com