Dense point-shaped three-dimensional laser processing device

A technology of three-dimensional laser and processing equipment, which is applied in the direction of laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of low processing efficiency, achieve consistent processing effects, simplify the structure, and expand the effect of application scenarios

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

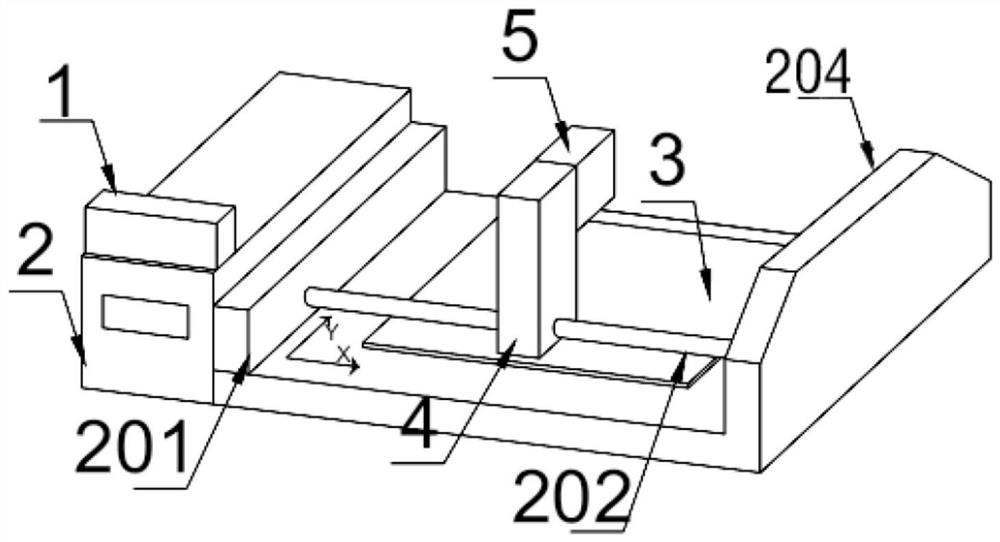

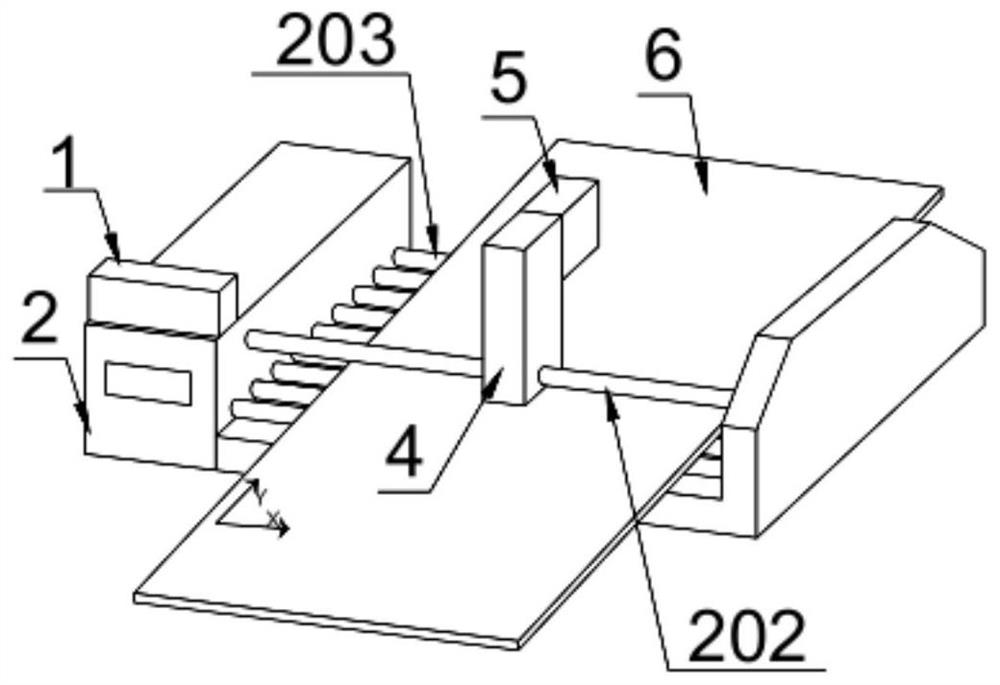

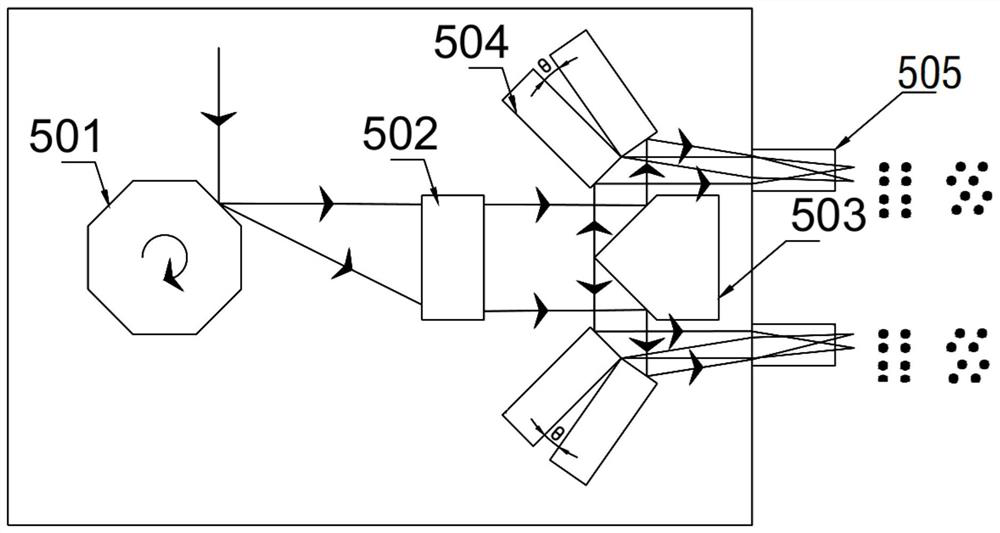

[0041]This embodiment provides a dense point-like three-dimensional laser processing device, which includes an X-direction translation guide rail 202, a work platform 4, a machine tool 2 arranged on one side of the work platform 4, a fixed plate arranged on the other side of the work platform 4, and a set On the laser 1 on the machine tool 2, one end of the X-direction translation guide rail 202 is installed on the machine tool 2, and the other end is installed on the fixed plate 204, and the described working platform 4 is installed on the X-direction translation guide rail 202, and the working platform 4 is provided with a laser-intensive point-shaped laser processing head 5 .

[0042] Preferably, the laser-intensive point-shaped laser processing head 5 moves on the working platform 4 along the Z direction, and the X direction is perpendicular to the Z direction.

[0043] When used for processing small parts 3, the machine tool 2 is provided with a Y-direction translation gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com