Laser cutting machine

A technology of laser cutting machine and cutting mechanism, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve problems such as safety accidents, easy fatigue of cutting materials, and occurrence, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

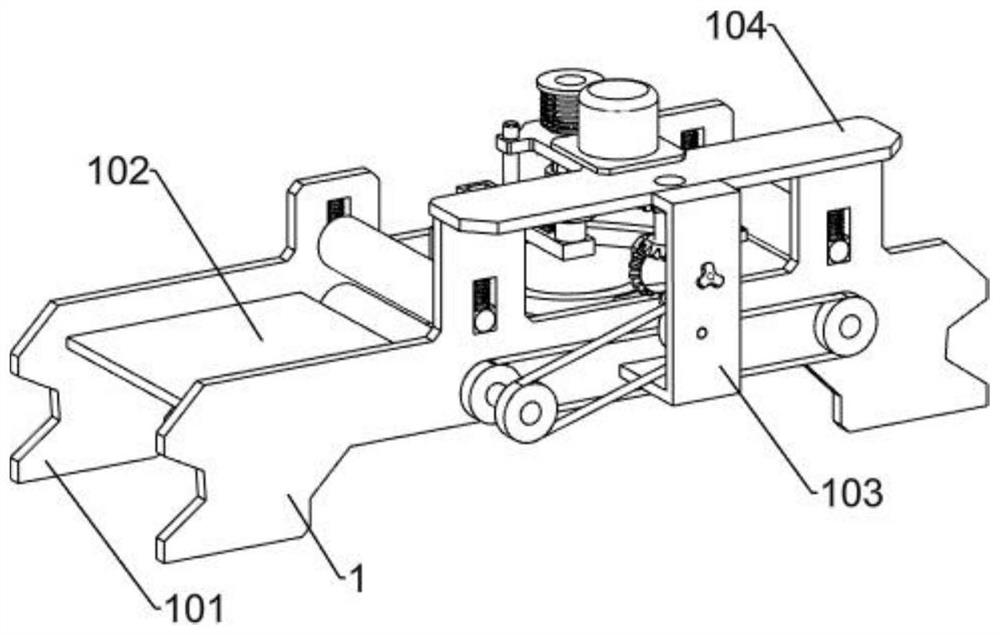

[0030] A laser cutting machine such as figure 1 As shown, it includes a support frame, a power mechanism and a cutting mechanism, including the first support plate 1 of the support frame, the second support plate 101, the connecting plate 102, the vertical support 103, the upper support 104 and the side support 105, the first support plate 1 and the second support plate 101 are symmetrically arranged front and rear, the front and rear sides of the connecting plate 102 are respectively fixedly connected to the inside of the first support plate 1 and the second support plate 101, and the lower end of the vertical support 103 is fixedly connected to the front of the first support plate 1 side, the lower sides of both ends of the upper bracket 104 are respectively fixedly connected to the first support plate 1, the front side of the upper bracket 104 is fixedly connected to the upper end of the vertical bracket 103, and the right end of the side bracket 105 is fixedly connected to ...

Embodiment 2

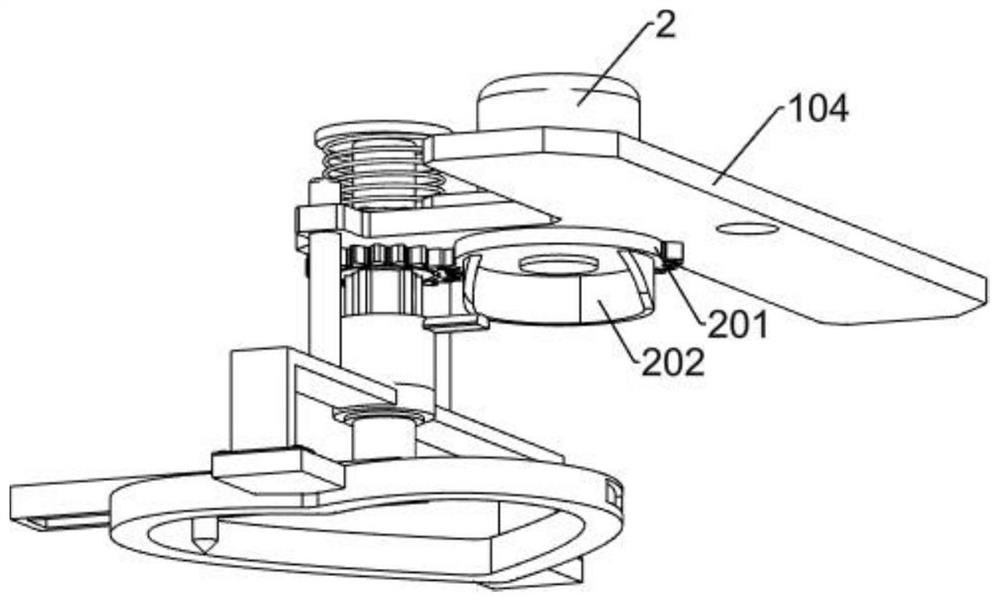

[0033] On the basis of Example 1, such as figure 2 , Figure 4 and Figure 5 As shown, the power mechanism includes a motor 2, a missing gear 201, a circular cam 202, a spline sleeve 203 and a first spur gear 204, the motor 2 is fixedly connected to the upper side of the upper bracket 104, and the missing gear 201 is fixedly connected to the top of the motor 2 The power output shaft, the circular cam 202 is fixedly connected to the underside of the missing gear 201, the upper end of the spline sleeve 203 is rotatably connected to the left end of the upper bracket 104, the first straight gear 204 is fixedly connected to the lower end of the spline sleeve 203, the first straight The gear 204 meshes with the missing gear 201 .

[0034]Start the power mechanism after turning on the power supply during use, the motor 2 rotates and drives the missing gear 201 to rotate, and the missing gear 201 rotates to drive the circular cam 202 to rotate. The rotation of the straight gear 20...

Embodiment 3

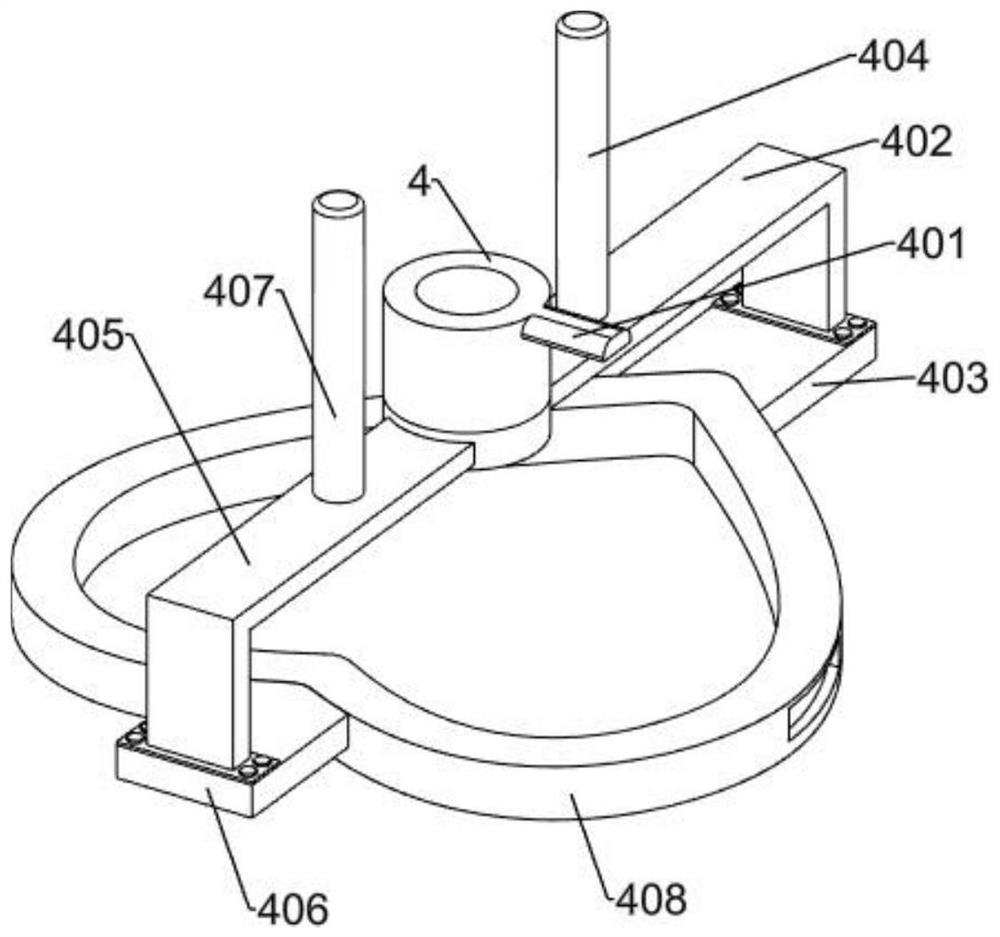

[0038] On the basis of Example 2, such as Figure 2-Figure 5 As shown, the track control mechanism includes a connecting sleeve 4, a touch plate 401, a first connecting frame 402, a first fixing plate 403, a first slide bar 404, a second connecting frame 405, a second fixing plate 406, a second sliding Rod 407 and cutting guide rail 408, the connecting sleeve 4 is rotatably connected to the lower part of the rotating shaft 3, the touch plate 401 is fixedly connected to the upper end of the connecting sleeve 4, the left end of the first connecting frame 402 is fixedly connected to the lower end of the connecting sleeve 4, the first fixed The right end of the plate 403 is connected to the lower right end of the first connecting frame 402 by bolts, the lower end of the first sliding rod 404 is fixedly connected to the upper side of the first connecting frame 402 near the end of the connecting sleeve 4, and the first sliding rod 404 slides with the upper bracket 104 connection, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com