Automatic assembling device and method for large-length-diameter-ratio shaft and hole

An automatic assembly device and a technology with a large aspect ratio, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as easy interference with the inner wall of the hole, damage to the shaft workpiece, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

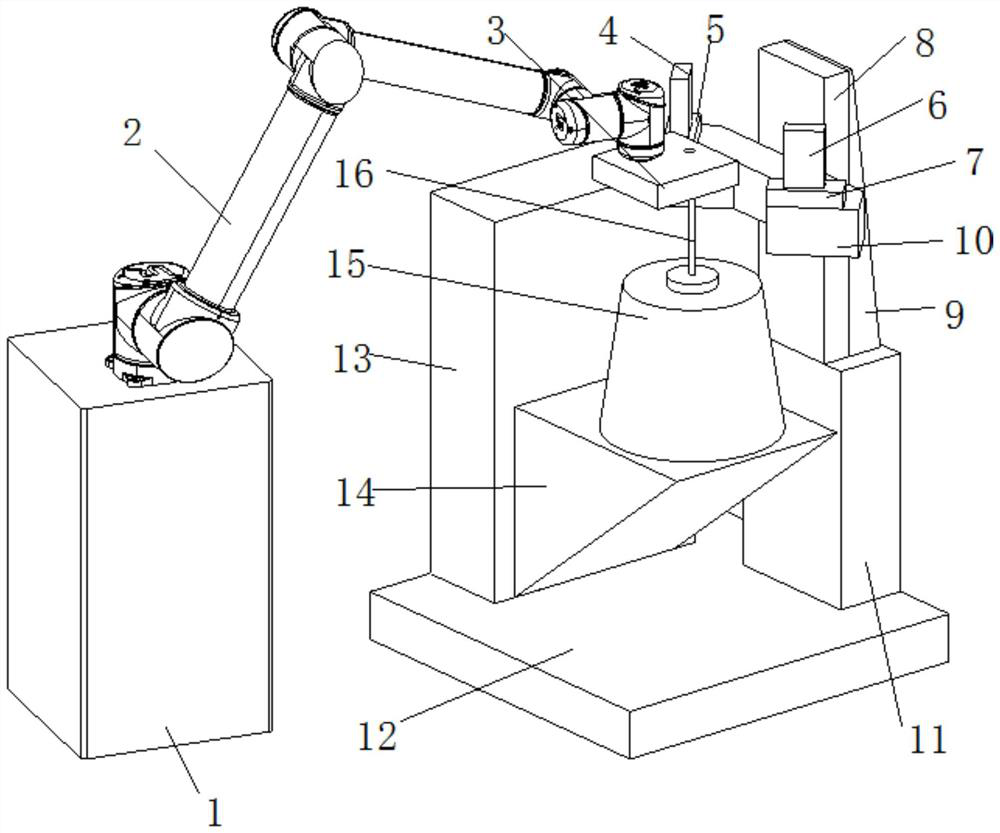

[0039] see figure 1 , a large aspect ratio shaft hole automatic assembly device, including:

[0040]A clamping unit, which includes: a workpiece with a hole 3 and a clamping member for clamping the workpiece with a hole 3, the clamping member can adjust the position and angle of the workpiece with a hole 3;

[0041] The attitude adjustment assembly unit includes: a shaft workpiece 16, a first lifting assembly, an attitude adjustment mechanism 15 for adjusting the position and angle of the shaft workpiece 16, and the first lifting assembly is used to control the lifting of the attitude adjustment mechanism 15, The shaft workpiece 16 is installed on the top surface of the attitude adjustment mechanism 15;

[0042] A measuring unit, which includes: a second lifting assembly and a measuring assembly, the second lifting assembly includes a second support plate 10, the second lifting assembly is used to control the lifting of the second support plate 10, the measuring assembly Ins...

Embodiment 2

[0058] The present invention also provides an automatic assembly method for a shaft hole with a large length-to-diameter ratio, which includes the following steps:

[0059] S1: Move the workpiece 3 with a hole through the clamping member to the area above the shaft workpiece 16, and adjust the laser line height of the first line laser profile sensor 6 and the second line laser profile sensor 4 to the height of the shaft workpiece 16 through the second lifting assembly At the top, record the position Z0 of the first lifting component at this time;

[0060] S2: Adjust the horizontal position of the first line laser profile sensor 6 and the second line laser profile sensor 4 through the first horizontal movement axis 7 and the second horizontal movement axis 5, so that the axis workpiece 16 is between the first line laser profile sensor 6 and the second line Within the measurement range of the laser profile sensor 4;

[0061] S3: Elevate the position of the shaft workpiece 16 at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com