Automatic buoy drilling device for fishing gear

A drilling device and float technology, which is applied in metal processing and other directions, can solve the problems of float damage, lower production efficiency, easy injury, etc., and achieve the effect of reducing hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

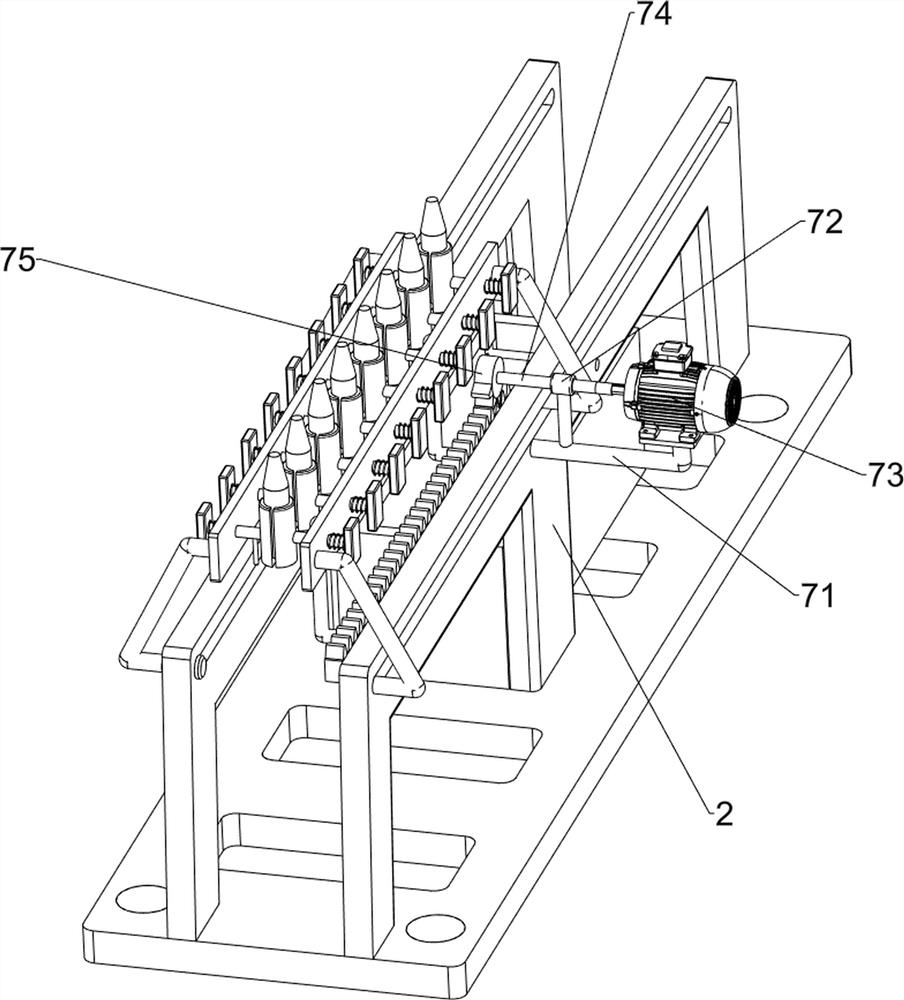

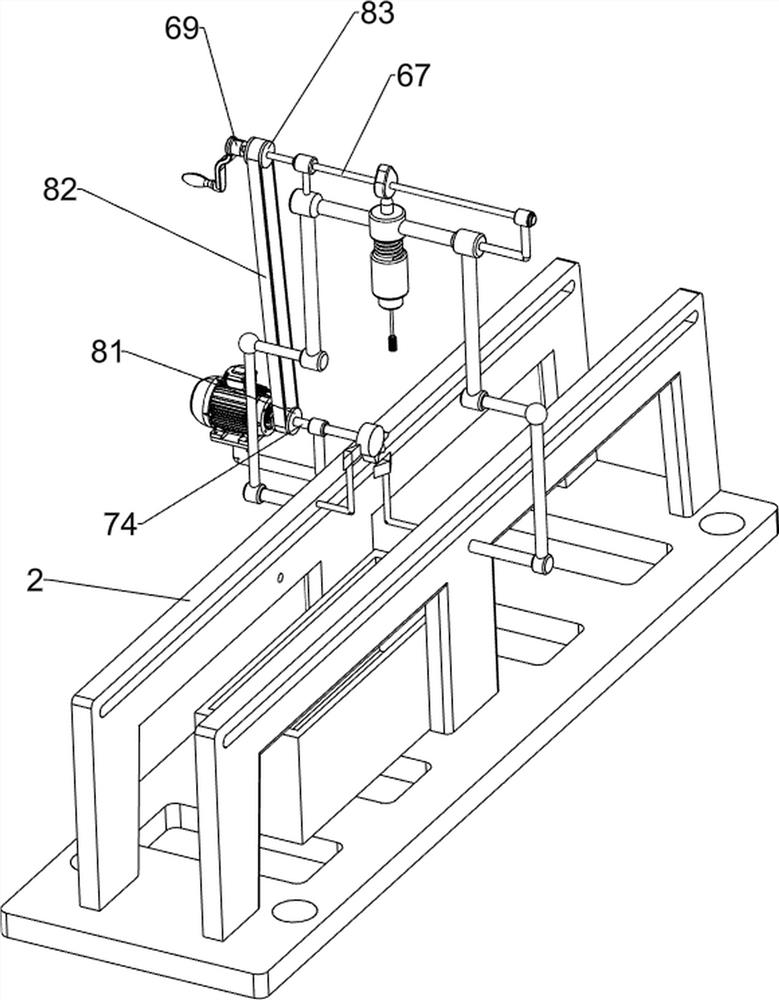

[0027] A floating automatic drilling device for fishing gear, such as figure 1 As shown, it includes a base 1, a support column 2, a collector 3, a feeding mechanism 4, a clamping mechanism 5 and a drilling mechanism 6. The top of the left and right sides of the base 1 is provided with a support column 2, and the top of the front side of the base 1 is provided with The collector 3 is provided with a feeding mechanism 4 between the rear sides of the two supporting columns 2 , a drilling mechanism 6 is provided between the middle outer walls of the two supporting columns 2 , and a clamping mechanism 5 is provided on the feeding mechanism 4 .

[0028] When people need to drill the fishing gear float, they can use this fishing gear float automatic drilling device. First, people need to put the float in the 5 parts of the clamping mechanism, and then manually rotate the 6 parts of the drilling mechanism to make the drilling mechanism The 6 parts can drill the clamped floats. When o...

Embodiment 2

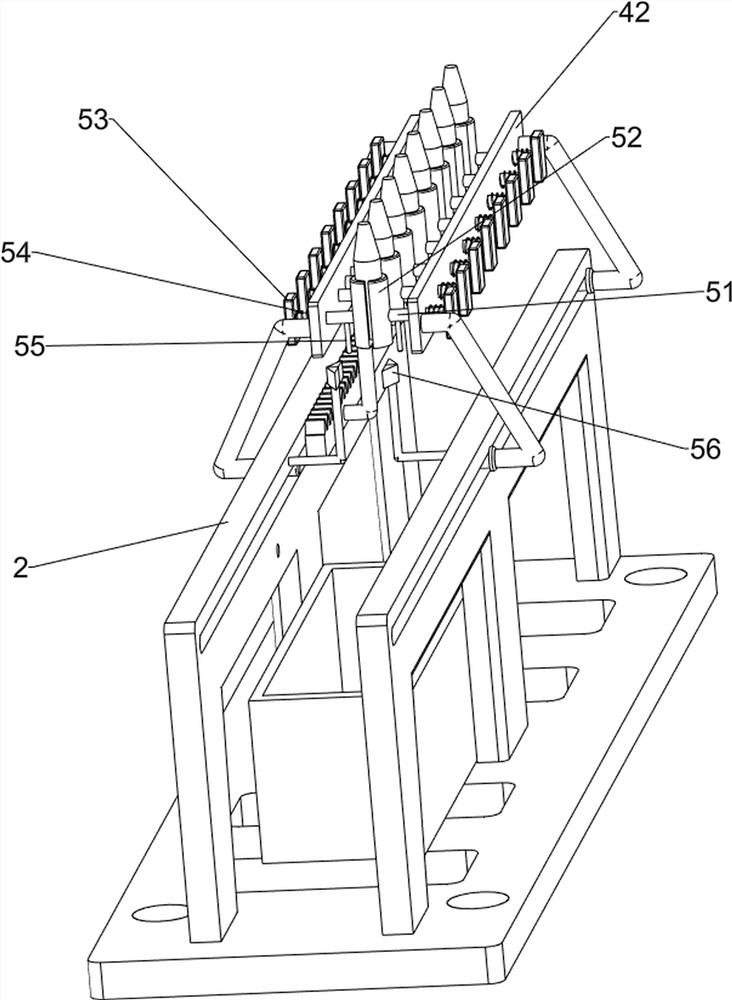

[0030] On the basis of Example 1, such as Figure 2-7 As shown, the feeding mechanism 4 includes a fixed bracket 41, a baffle plate 42 and a rack 43, and the rear sides of the support columns 2 on the left and right sides are slidingly symmetrically provided with a fixed bracket 41, and between the fixed brackets 41 on the left and right sides, a fixed bracket 41 is arranged. A baffle 42 is arranged, and the inner wall of the baffle 42 on the left side is provided with a rack 43 .

[0031] After people clamp the float in the clamping mechanism 5, they push the fixed bracket 41 forward on the support column 2, and the fixed bracket 41 drives the baffle plate 42 to move forward, thereby driving the clamped float to move forward and make it move Drilling is carried out at the drilling mechanism 6, the baffle plate 42 drives the rack 43 to move forward, and after the drilling is completed, the fixing bracket 41 is pushed backward to make it reset.

[0032] The clamping mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com