A slurry mixing reactor for polyester production

A reaction kettle and slurry technology, applied in feeding devices, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as restart resistance, easy settlement, difficult to observe the completion of the slurry reaction, etc., to achieve convenience The effect of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

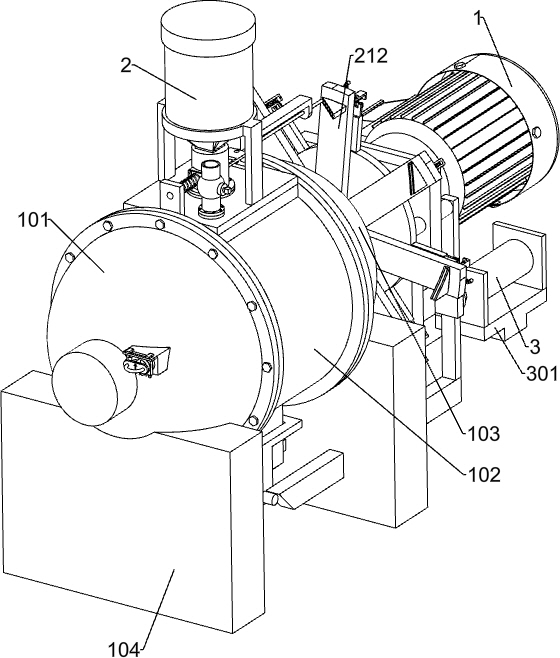

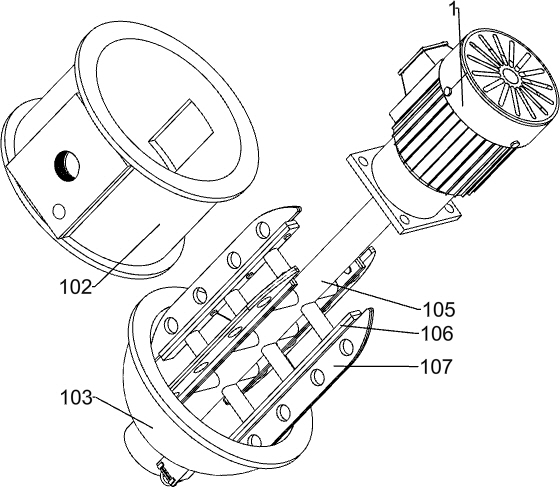

[0042] A slurry mixing reactor for polyester production, such as Figure 1-12 As shown, it includes a power motor 1, a barrel front section 101, a barrel middle section 102, a barrel rear section 103, a support plate 104, a rotating shaft 105, a stirring frame 106, a first mounting frame 108, intermittent feeding mechanism and discharge Mechanism, there are two support plates 104, the top of the front support plate 104 is connected with a barrel front section 101, the front side of the barrel front section 101 is provided with a through hole at the right position, and the top of the rear support plate 104 is connected with a The rear section 103 of the barrel body is provided with a through hole in the center of the rear side of the rear section 103 of the barrel body. A middle barrel section 102 is connected between the front section 101 of the barrel body and the rear section 103 of the barrel body. 101 and the rear section 103 of the barrel together form a reactor, the top ...

Embodiment 2

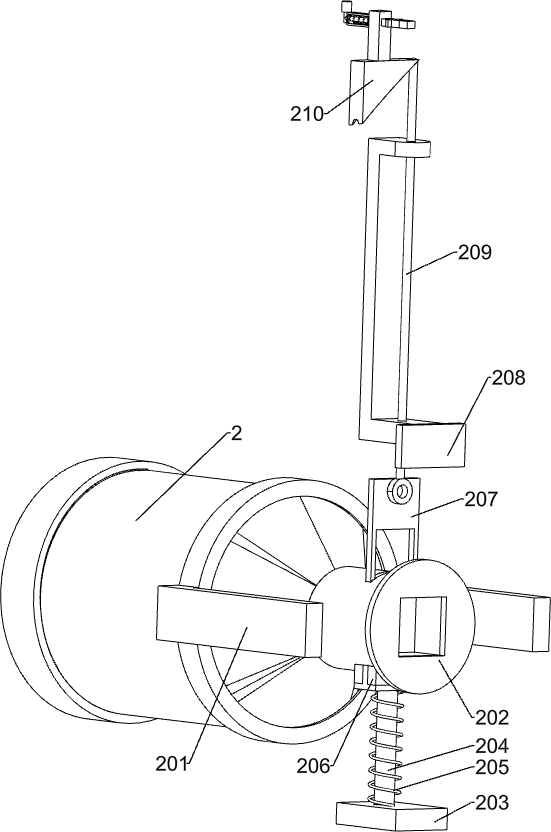

[0045] On the basis of Example 1, as figure 1 and Figure 3-4 As shown, the intermittent feeding mechanism includes a feeding barrel 2, a support frame 201, a feeding interface 202, a fixing plate 203, a first sliding rod 204, a first spring 205, a limit block 206, a baffle plate 207, a first fixed The frame 208, the second sliding rod 209, the triangular inclined block 210 and the rotating disc 212, a feeding interface 202 is threadedly connected to the top of the middle section 102 of the barrel body, and the raw material enters the middle section 102 of the barrel body through the feeding interface 202, and the feeding interface 202 A through hole in the front-rear direction is opened in the middle of the barrel. A support frame 201 is fixedly connected to the top of the middle section 102 of the barrel. The top of the support frame 201 is an annular frame. A feeding barrel 2 is installed in the supporting frame 201. Connected to the annular frame of the support frame 201,...

Embodiment 3

[0050] On the basis of Example 2, as figure 2 As shown, a stirring blade 107 is also included. Each stirring frame 106 is installed with a stirring blade 107. The middle of the stirring blade 107 is provided with a plurality of through holes. The position where the stirring blade 107 contacts the inner wall of the reactor is soft.

[0051] During stirring, the stirring blade 107 installed on the stirring frame 106 will rotate along with it, and the edge of the stirring blade 107 is in close contact with the edge of the inner wall of the reactor, so that the raw materials on the inner wall of the reactor can be scraped off. The middle of the stirring blade 107 is provided with four There are through holes, so that the raw materials can be stirred more uniformly, and the function of preventing the raw materials from sticking to the inner wall and stirring the raw materials more uniformly is realized.

[0052] like Figure 4 As shown, a top cover 211 is also included, and a top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com