Earth and rockfill dam foundation deep soft soil treatment method and earth and rockfill dam

A technology for soft soil treatment and earth-rock dams, which is applied in the direction of infrastructure engineering, filling, dams, etc., can solve problems such as difficulties in the construction of high earth-rock dams, and achieve the effects of shortening the construction period, reducing the scope of excavation, and saving engineering volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

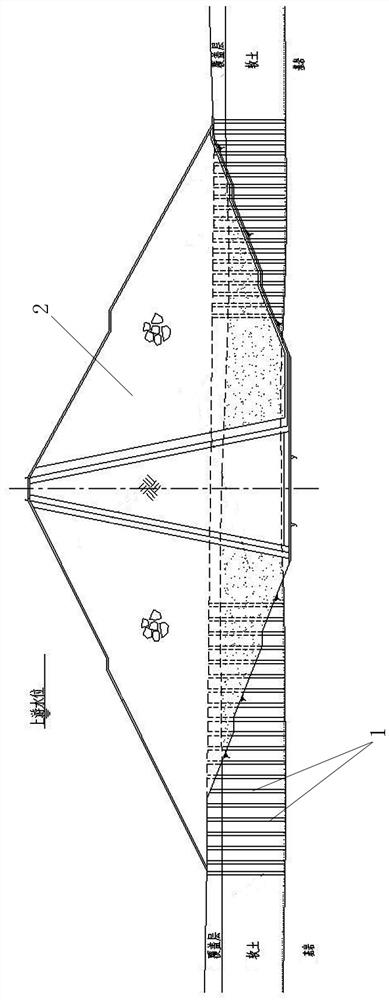

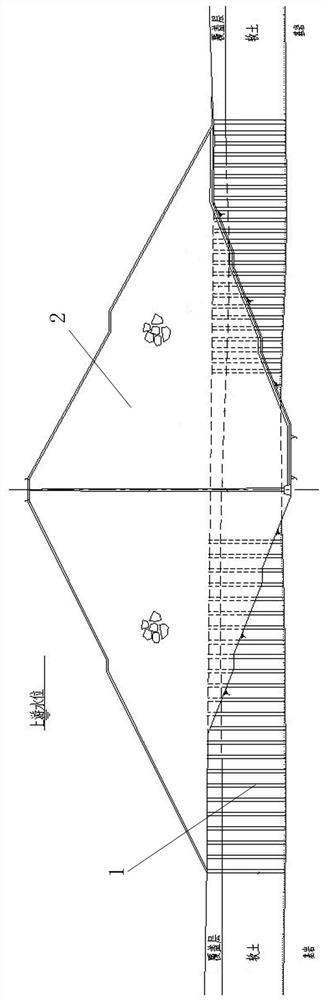

[0039] Embodiment 1: This embodiment is a deep soft soil treatment method for an earth-rock dam foundation, comprising the following steps:

[0040] Before construction, the excavation surface of the dam foundation is determined according to the site conditions and the design requirements of the dam. The excavation surface of the dam foundation is in the shape of a groove as a whole. The bottom surface of the tank and the downstream tank walls are slopes that slope downward toward the bottom of the tank;

[0041] Before the excavation of the soft soil of the dam foundation, the construction of vibratory gravel piles is carried out on the foundations upstream and downstream of the anti-seepage body of the dam. Stones are only backfilled with gravel below the excavation surface of the dam foundation, and gravel piles are formed below the excavation surface of the dam foundation (the gravel piles are mainly arranged for the soft soil layer, if the soft soil layer is not distribut...

Embodiment 2

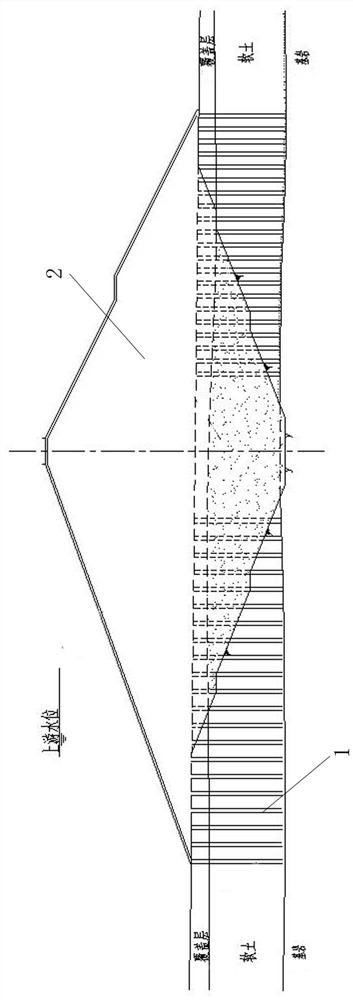

[0082] Embodiment 2: This embodiment is basically the same as Embodiment 1. The only difference is that the excavation of the dam foundation can be carried out in two phases. The second phase of excavation was carried out.

[0083] Such as Figure 18 As shown, in this embodiment, the covering layer above the soft soil layer is excavated to a certain depth before the construction of the vibrating gravel pile, and the excavation area is the area covered by the dam body.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com