Construction method for extruding and expanding foundation in soft foundation area

A technology for foundation construction and base, applied in foundation structure engineering, construction, sheet pile wall, etc., can solve the problems of large labor cost, long construction period, low construction efficiency, etc., to improve construction efficiency, small settlement, save money cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

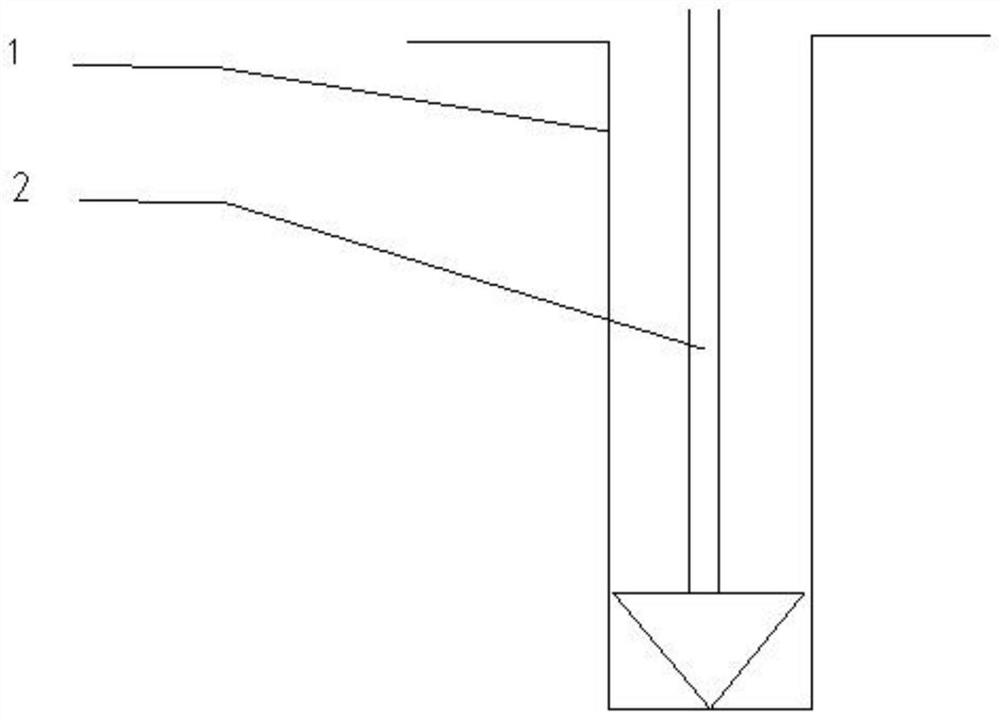

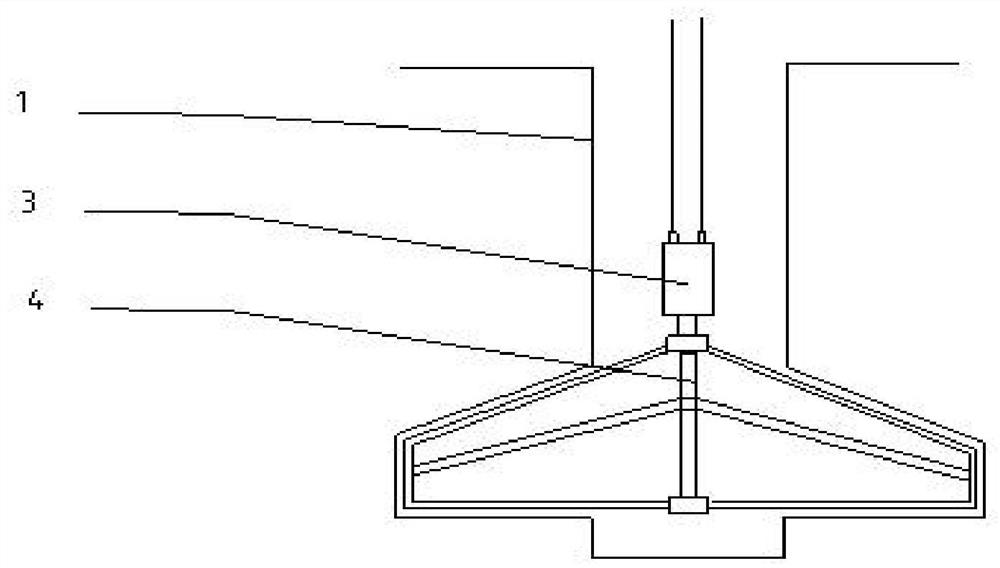

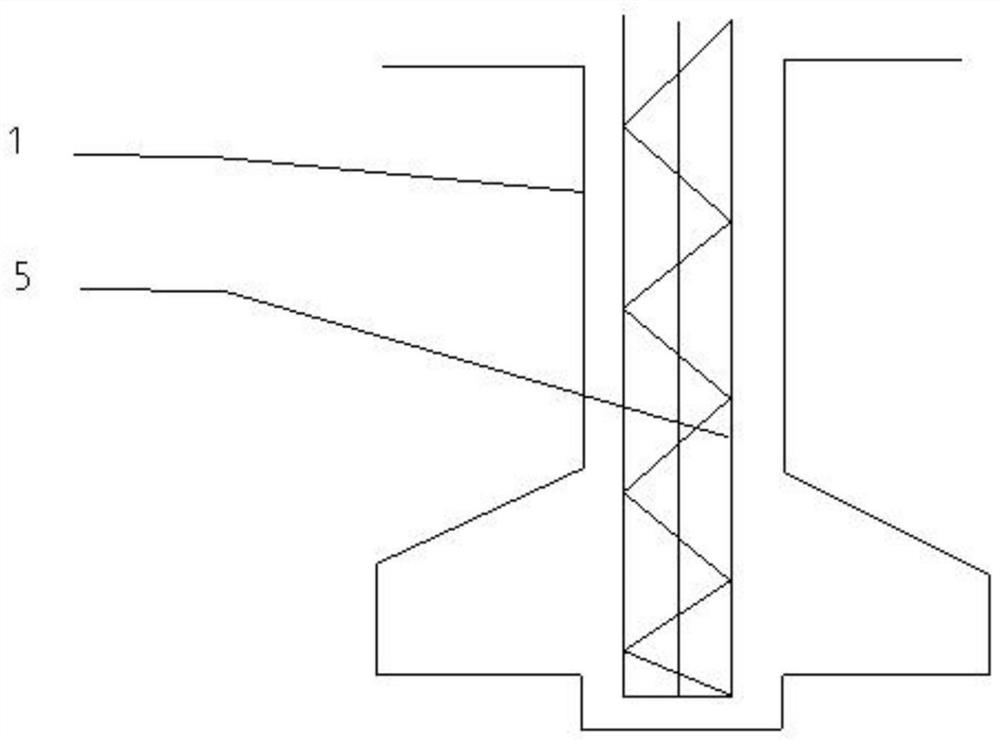

[0022] Such as Figure 1-4 As shown, a kind of soft ground area extruded and expanded foundation construction method of the present embodiment, its steps are:

[0023] The first step is to determine the size and depth of the foundation drilling 1 and the drilling equipment 2 to be used according to the requirements of the design drawings, configure the corresponding reinforcement as required, and make the foundation reinforcement cage 5 in time for use;

[0024] The second step is to measure and locate, determine the location of the hole, put the drilling equipment 2 in place, carry out the foundation drilling 1 to 200mm above the design depth value, and continue the construction after the remaining 200mm is cleaned and measured;

[0025] In the third step, after forming the hole, put it into the hydraulic hole reaming device 4 for correction, and use the hydraulic transmission device 3 to ream the hole to reach the predetermined width and stress, forming an extrusion effect; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com