Gas trapping device for space suction type electric propulsion system

A gas-capturing and air-breathing technology, applied in thrust reversers, using plasma, machines/engines, etc., can solve problems such as low air capture efficiency and hinder air capture efficiency, and reduce the probability of reverse motion , Improve the effect of storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

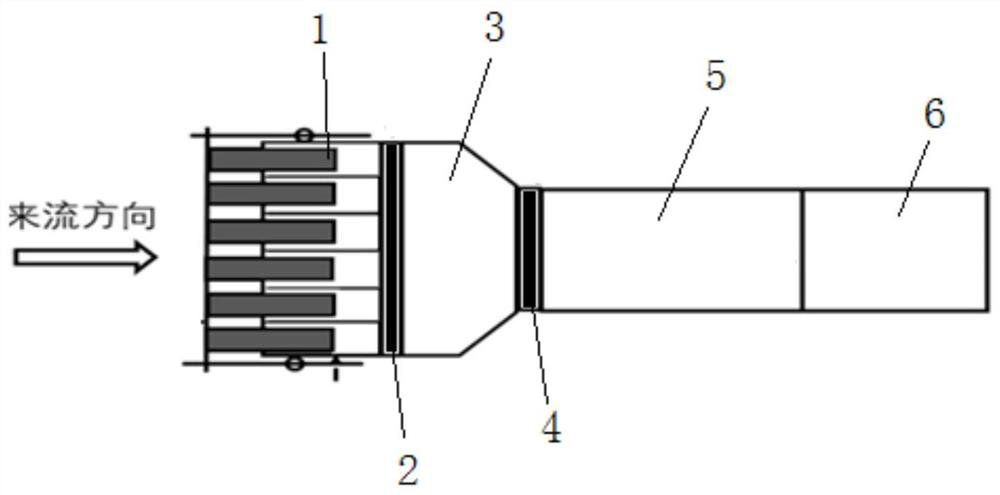

[0039] like figure 1 As shown, the present invention provides a gas capture device for a space-breathing electric propulsion system, the gas captured by the gas capture device is decelerated and pressurized by a pressurized storage device 5, and is driven by an electric thruster 6 spacecraft Proper thrust is provided during flight, and the gas trapping device includes a collimator main body 1 and a gas trapping device main body 3 in sequence along the gas flow direction. The collimator main body 1 is installed at the gas inlet end of the main body 3 of the gas trapping device.

[0040] The collimator main body 1 is a hollow tubular telescopic assembly, the pipe of the collimator main body 1 is parallel to the flow direction of air molecules, and the collimator main body 1 forms a plurality of narrow and adjustable length gas traps Flow channel to increase the gas capture rate.

[0041]Specifically, the collimator main body 1 has a hollow cylindrical structure with openings a...

Embodiment 2

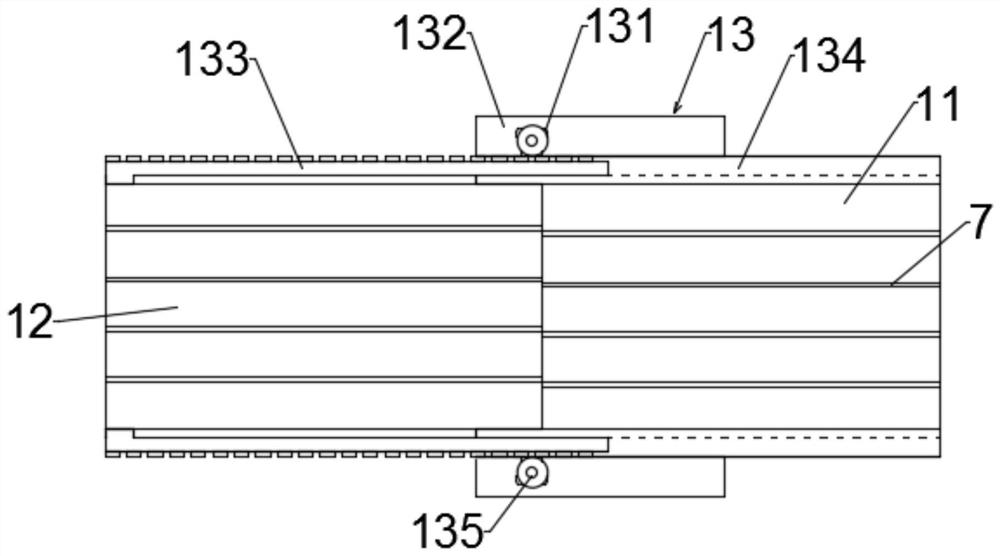

[0065] This embodiment provides an embodiment of the collimator body 1 corresponding to Embodiment 1, as image 3 As shown, each of the collimator main bodies 1 includes a fixed part 11, a telescopic part 12 and a driving part 13, and the fixed part 11 is used for fixed connection with the first molecular pump, wherein the first molecular pump is installed on Between the fixed part 11 and the parallel section 31 of the main body 3 of the gas trapping device; axial sliding; the drive part 13 is used to drive the telescopic part 12 to expand and contract along the axial direction of the fixed part 11 during space flight to adjust the length of the collimator main body 1, and the first spacer The plate 7 is disposed inside the fixed part 11 , and the telescopic part 12 is driven by the driving part 13 to completely shrink and overlap the fixed part 11 .

[0066] The collimator body 1 is located at the front end of the parallel section 31 of the gas capture device body 3 , and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com