Low-temperature high-pressure hydrogen storage pressure vessel and use method thereof

A pressure vessel, low-temperature and high-pressure technology, applied in the field of hydrogen storage and transportation, can solve the problems of high hydrogen storage pressure, slow hydrogen absorption and discharge process, and easy pulverization, and achieve high storage pressure, fast hydrogen charging and discharging rate, and low-temperature environment performance. The effect of low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

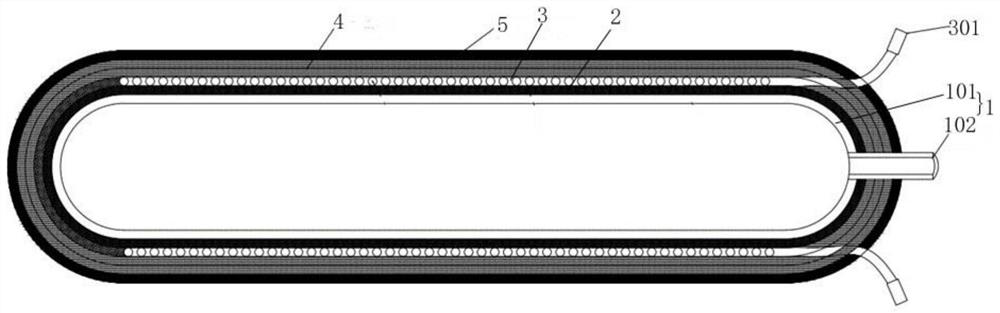

[0050] like figure 1 As shown, this embodiment provides a 70MPa low temperature and high pressure hydrogen storage pressure vessel, and the low temperature and high pressure hydrogen storage pressure vessel includes a multi-layer design:

[0051](1) The metal liner 1 of the pressure vessel is made of Dewar steel material, with a hemispherical head, the bottle body is 6m long, the inner diameter is 0.53m, and the wall thickness is 10mm;

[0052] (2) The reinforced braided layer 2 of the pressure vessel is wound with 6 layers of carbon fibers and 2 layers of aramid fibers;

[0053] (3) The heat exchange pipe 3 is made of stainless steel, the inner diameter of the pipe is 10mm, and the wall thickness is 2mm. Liquid nitrogen or low-temperature nitrogen is used as the refrigerant, and normal temperature or heated nitrogen is used as the heat medium;

[0054] (4) The cold insulation layer 4 adopts three layers of aerogel felt pads, and the thickness of a single layer is 10 mm.

[...

Embodiment 2

[0061] This embodiment provides another 40MPa low temperature and high pressure hydrogen storage pressure vessel. The low temperature and high pressure hydrogen storage pressure vessel includes a multi-layer design:

[0062] (1) The metal liner 1 of the pressure vessel is made of Dewar steel material, with a hemispherical head, the bottle body is 6m long, the inner diameter is 0.53m, and the wall thickness is 10mm.

[0063] (2) The reinforced braided layer 2 of the pressure vessel is wound with 6 layers of carbon fibers.

[0064] (3) The heat exchange pipe 3 is made of stainless steel, the inner diameter of the pipe is 10mm, and the wall thickness is 2mm. Liquid CO2 is used as the refrigerant, and normal temperature or heated nitrogen is used as the heat medium.

[0065] (4) The cold insulating layer 4 adopts three layers of aerogel felt pads, and the thickness of the single layer is 10 mm.

[0066] (5) The material of the outer sheath layer 5 is made of high-density polyethy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com