Magnesium hydride hydrogen storage composite material containing porous material and preparation method thereof

A technology of porous materials and composite materials, applied in the field of magnesium hydride hydrogen storage composite materials and their preparation, can solve the problems of slow hydrogen absorption and desorption, high temperature, poor reaction kinetic performance, etc., and achieves improved mechanical strength, easy handling, The effect of increasing hydrogen storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

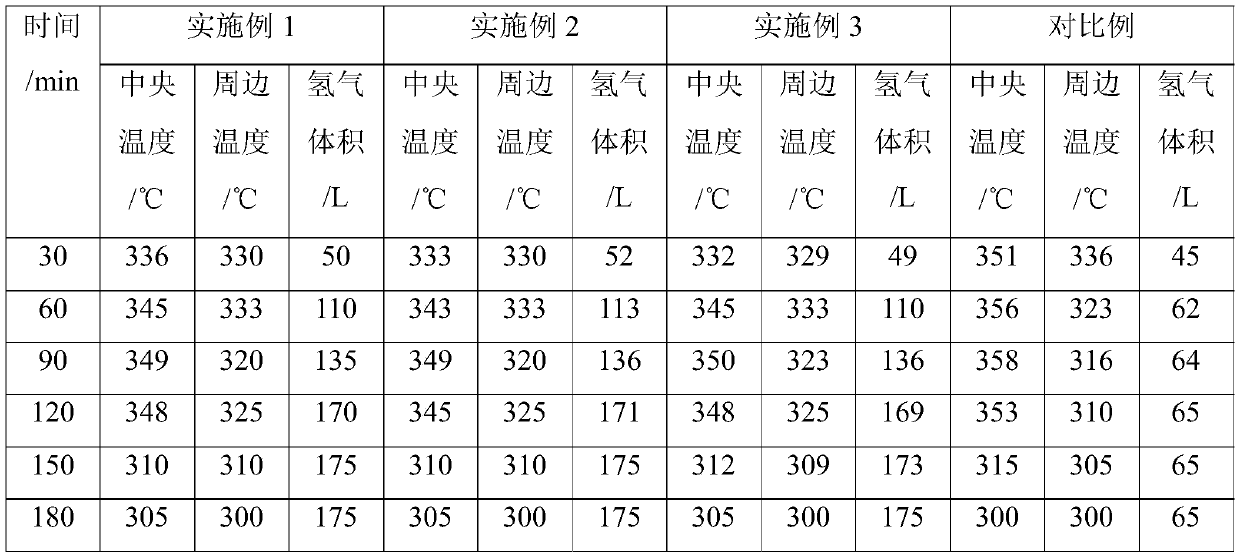

Examples

Embodiment 1

[0029] The magnesium hydride hydrogen storage composite material containing porous material comprises the following steps:

[0030] In a sealed mixer (located in a glove box under controlled atmosphere), 47.5 g of activated magnesium hydride powder with an average grain size of 4.0 μm was mixed with 35 g of expanded natural graphite with an average grain size of 6.0 μm (ENG ) for mixing.

[0031] The powder mixture is then poured into molds in a hardened steel pelletizer, also located in the glove box. The granulator is taken out from the glove box in the airtight bag and placed under the press.

[0032] The passing strength is 1t / cm 2 (10 8 Pa) uniaxial compression to compress the powder in the granulator, that is.

Embodiment 2

[0034] The magnesium hydride hydrogen storage composite material containing porous material comprises the following steps:

[0035] In a sealed mixer (glove box under controlled atmosphere), 45 g of activated magnesium hydride powder with an average grain size of 7.0 μm was mixed with 45 g of activated alumina with an average grain size of 20 μm.

[0036] The powder mixture is then poured into molds in a hardened steel pelletizer, also located in the glove box. The granulator is taken out from the glove box in the airtight bag and placed under the press.

[0037] The passing strength is 1t / cm 2 (10 8 Pa) uniaxial compression to compress the powder in the granulator, that is.

Embodiment 3

[0039] The magnesium hydride hydrogen storage composite material containing porous material comprises the following steps:

[0040] In a sealed mixer (glove box under controlled atmosphere), 45 g of activated magnesium hydride powder with an average grain size of 3.5 μm were mixed with 100 g of silica with an average grain size of 30 μm.

[0041] The powder mixture is then poured into molds in a hardened steel pelletizer, also located in the glove box. The granulator is taken out from the glove box in the airtight bag and placed under the press.

[0042] The passing strength is 1t / cm 2 (10 8 Pa) uniaxial compression to compress the powder in the granulator, that is.

[0043] Examples 1-3 recovered compressed material with a diameter of 8 cm, and the material could be processed in an open environment for several minutes. However, it is preferable to store the composite material under a controlled atmosphere to avoid the risk of temperature rise and surface oxidation.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com