Carbon nanofiber, diffusion layer, membrane electrode, fuel cell and preparation method and application thereof

A carbon nanofiber and diffusion layer technology, which is applied in fuel cells, battery electrodes, fiber chemical characteristics, etc., can solve the problems of active site deactivation, large free path of material diffusion, and small pore volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

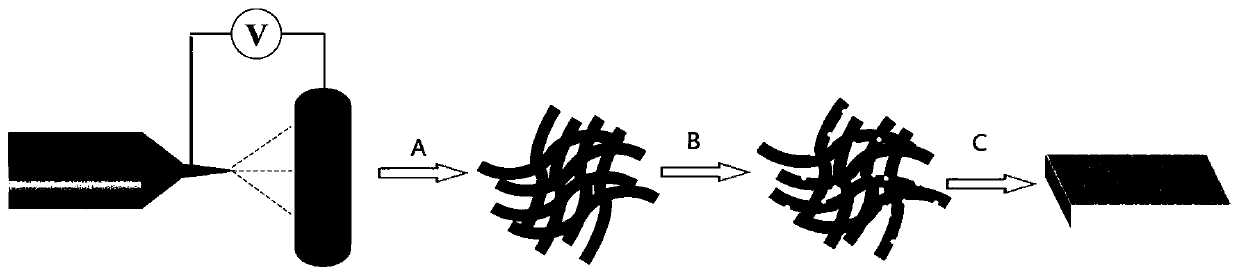

[0079] 1. Preparation of carbon nanofibers

[0080] S1. First, weigh 2g of polyacrylonitrile (PAN) powder, and dissolve it in 30g of DMF solution, with a mass fraction of 6.25wt%. Stir on a heated magnetic stirrer for 3 hours, control the temperature at 60°C, fully dissolve, and form a solution with PAN spinning precursor;

[0081] Transfer the spinning solution to the syringe, fix it on the electrospinning machine, set the spinning environment temperature to 45°C, control the humidity below 30% to 35%, the spinning voltage to 19kV, and the spinning solution supply speed to 0.10mm / min, wrap the cut aluminum foil on the drum, close the protection door of the spinning box, turn on the high-voltage power supply, and carry out double-nozzle electrospinning, adjust the drum collection speed to 80rpm, until the spinning liquid is consumed, and end the electrospinning.

[0082] S2. Take down the receiver, collect the polymer fiber cloth, and place it in a vacuum oven at 60° C. for ...

Embodiment 2

[0089] 1. Preparation of carbon nanofibers

[0090] S1. First, weigh 2 g of polyvinylpyrrolidone (PVP) powder, and dissolve it in 23 g of DMF solution, with a mass fraction of 8 wt%. Stir on a heated magnetic stirrer for 4 hours, control the temperature at 90°C, fully dissolve, and form a spinning solution with PVP;

[0091] Transfer the spinning solution to the syringe, fix it on the electrospinning machine, set the spinning environment temperature to 45°C, control the humidity at 30% to 60%, the spinning voltage to 17kV, and the spinning solution supply speed to 0.06mm / min , Wrap the cut aluminum foil on the drum, close the protection door of the spinning box, turn on the high-voltage power supply, perform double-nozzle electrospinning, adjust the drum collection speed to 80rpm, until the spinning solution is consumed.

[0092]S2. Take down the receiver, collect the polymer fiber cloth, and place it in a vacuum oven at 60° C. for drying.

[0093] S3. Arrange the dried fibe...

Embodiment 3

[0099] With polyacrylonitrile (PAN) and polyethylene oxide (PEO) blend (mass ratio is 1:1) to replace polyacrylonitrile (PAN) in embodiment 1, other conditions are identical with embodiment 1, obtain Black solid carbon nanofiber. The prepared carbon nanofibers were used to prepare a diffusion layer, and the preparation method was the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com