Hydraulic system for an automatic transmission of a motor vehicle

A technology of automatic transmission and hydraulic system, which is applied in the direction of mechanical equipment, components with teeth, transmission control, etc., and can solve problems such as functional failure of pressure accumulator and reduction of air pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

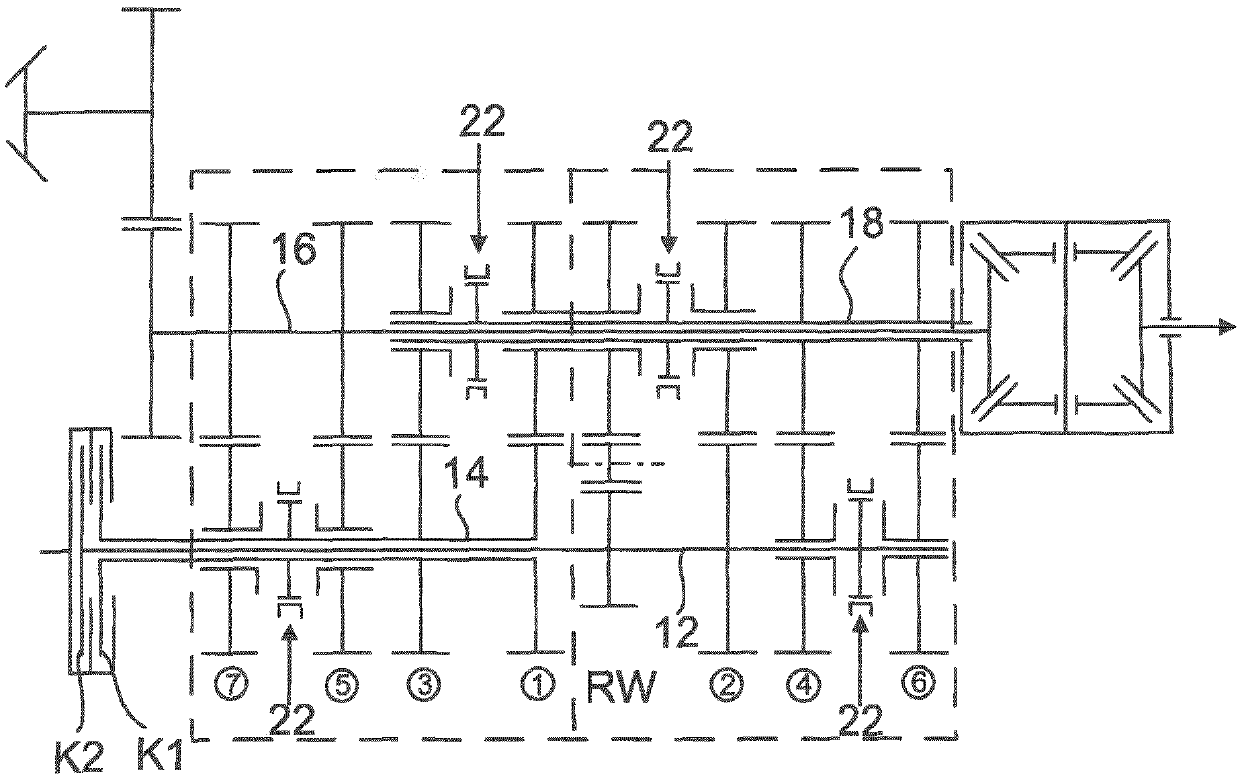

[0072] in figure 1 The schematic diagram shows a dual clutch transmission for an all-wheel drive motor vehicle. The dual clutch transmission has seven forward gears (see the framed numbers 1 to 7) and a reverse gear RW. Hereinafter, the dual clutch transmission is explained only to the extent necessary to understand the present invention. Therefore, the dual clutch transmission has two input shafts 12, 14, which are arranged coaxially with each other and can be alternately connected to a power source, such as an internal combustion engine, via two hydraulically actuable multi-plate clutches K1, K2. The input shaft 14 is implemented as a hollow shaft in which the input shaft 12 configured as a solid shaft extends. The two input shafts 12, 14 are transmitted to the output shaft 16 arranged axially parallel and the intermediate shaft 18 configured as a hollow shaft via the gear sets of the forward gear and the reverse gear. The gear sets of forward gears 1 to 7 respectively have...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com