Food waste dry matter decrement dryer re-utilizing vapor produced during drying

A food waste and dryer technology, applied in dryers, non-progressive dryers, drying, etc., can solve problems such as blocked pipeline condensation devices, reduce power consumption, simplify processes, and improve crushing and mixing efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Next, embodiments of the present invention will be described in detail with reference to the accompanying drawings.

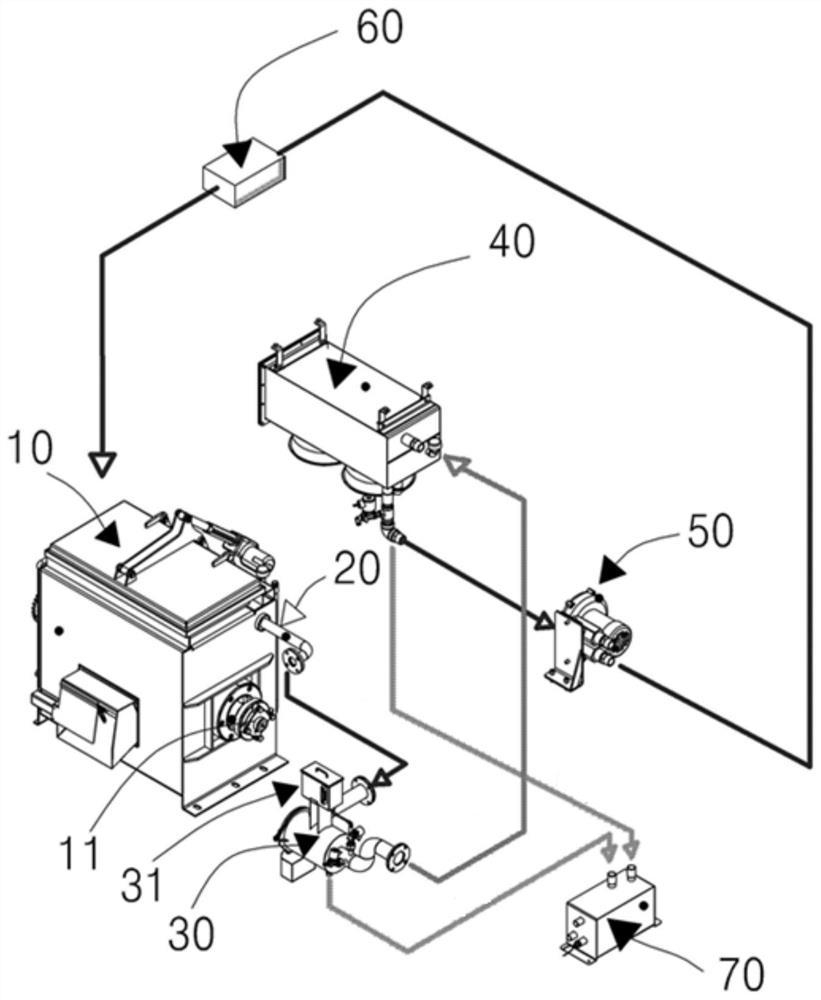

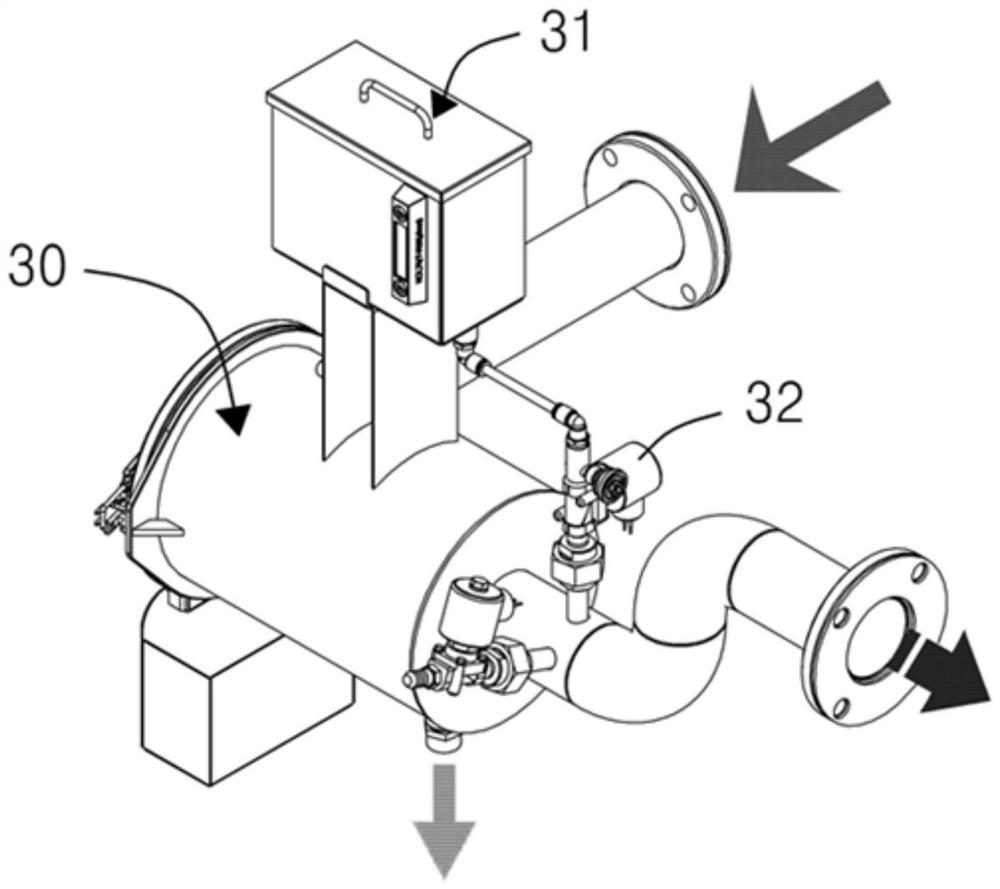

[0052] Such as Figure 1 to 8 As shown, the present invention includes: drying device 10 for pulverizing and drying food waste; the first dust filter 20 is disposed in the drying device 10 for filtering the vapor generated by the drying device 10. The foreign matter; the second dust filter 30, is used to filter the residual non-pure substance in the vapor that is not filtered by the first dust filter 20; the condensed device 40 for condensation through the second dust filter 30 The vapor is removed by removing moisture; the circulation device 50 does not discharge the distal vapor in the condensed device 40 to the atmosphere, but circulates it in the drying device 10 for drying food waste.

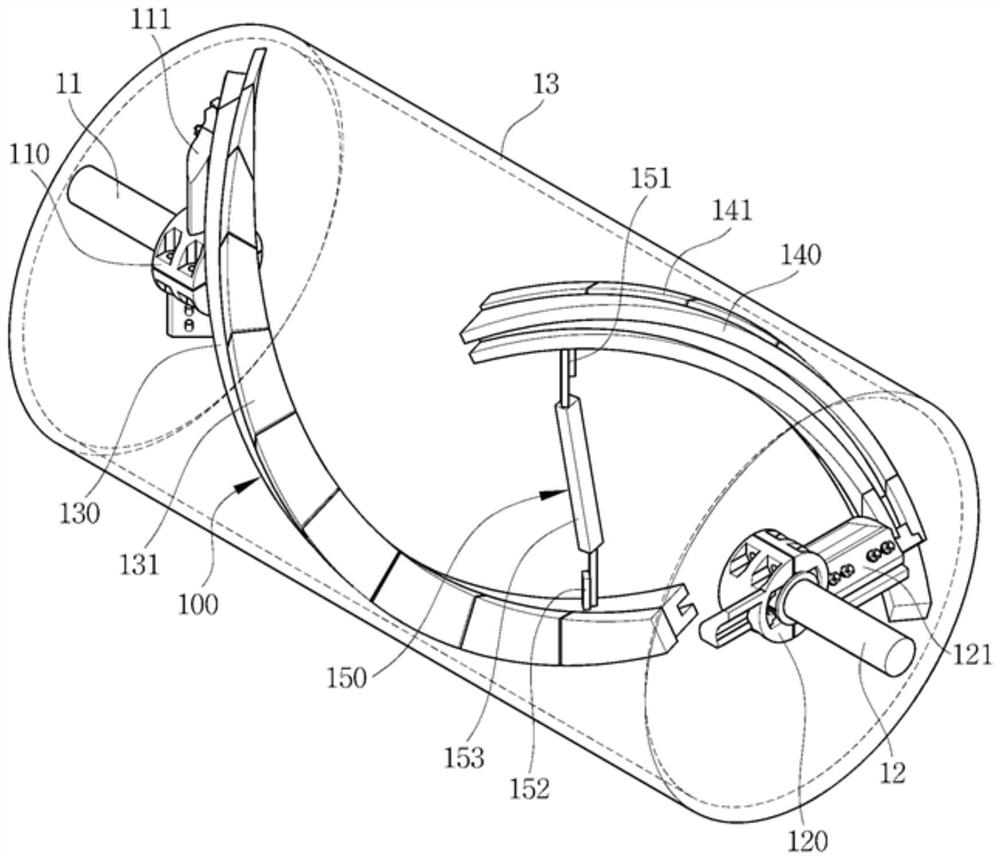

[0053] Drying apparatus 10 for pulverizing, stirring and drying when a food standard garbage bag is placed to a dry crushing device in a state of being loaded into food w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com