Rotary piston pump

A rotor pump and rotor technology, applied in pumps, rotary piston pumps, rotary piston machinery, etc., can solve problems such as unreliable sealing, reduced sealing effect, complicated processing technology, etc., and achieve reliable sealing, simple structure, and easy processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

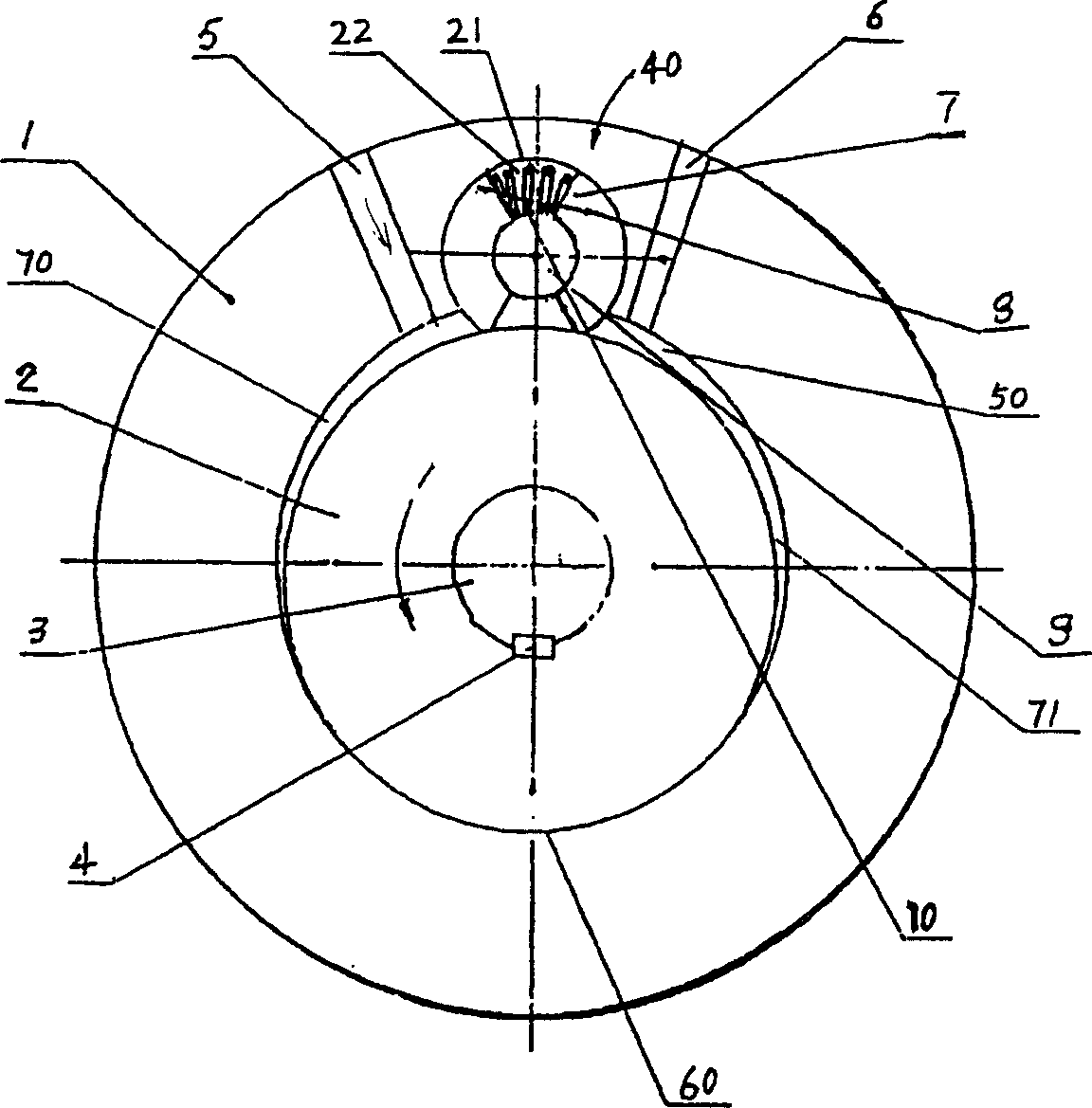

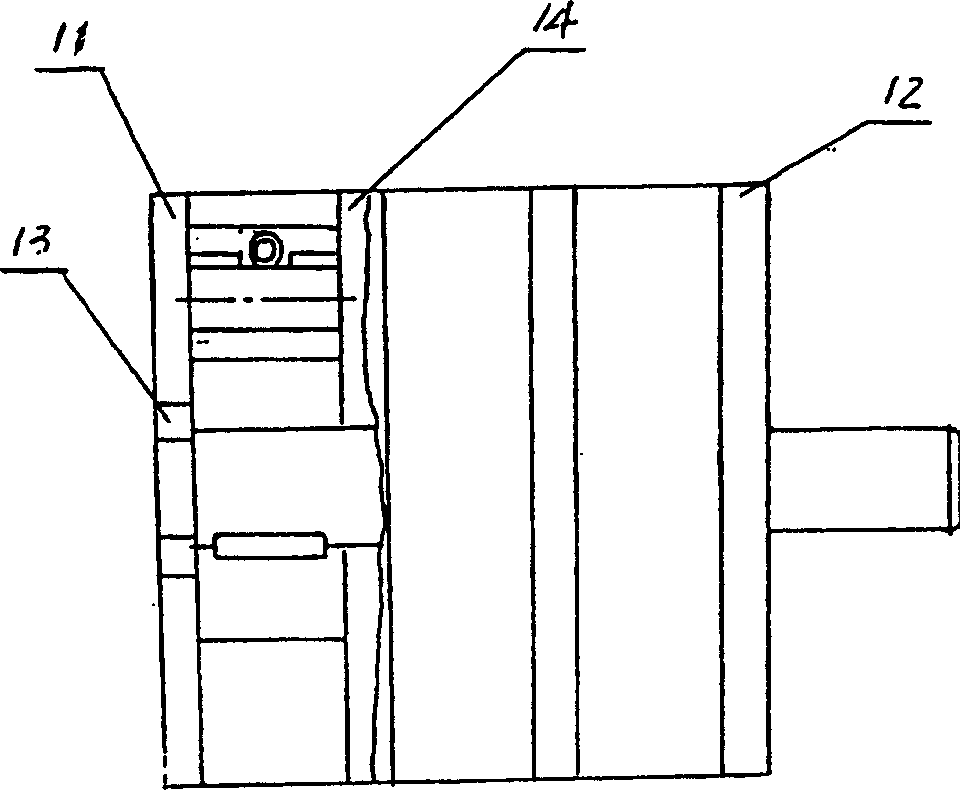

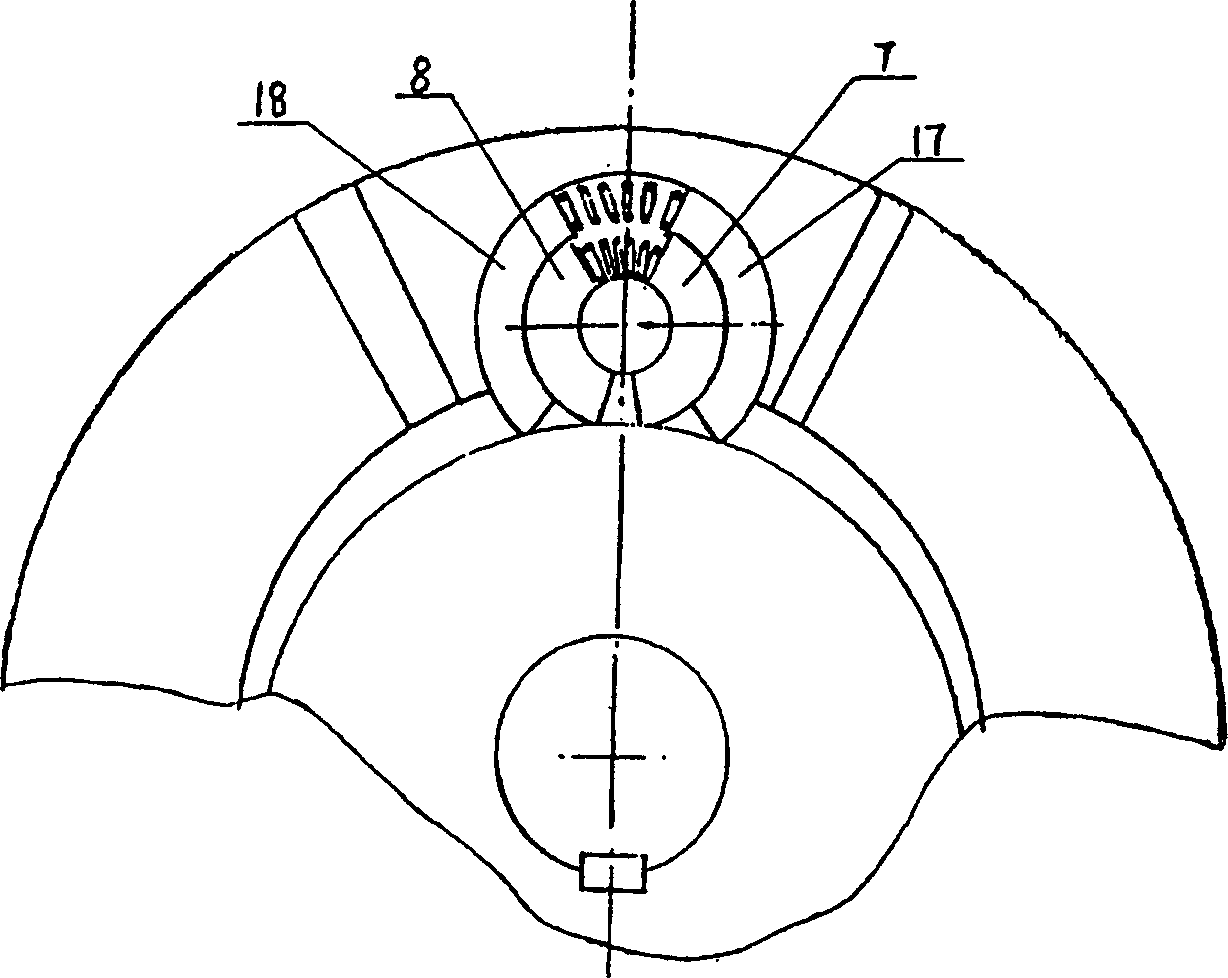

[0018] As shown in Figures 1 and 2, the rotor pump according to the first embodiment of the present invention includes a cylindrical cylinder 1, a cam rotor 2 is installed in the inner cavity of the cylinder 1, and a cam rotor 2 is installed between the outer peripheral surface of the cam rotor and the inner wall of the cylinder An axially extending sealed chamber 50 is formed. The rotor 2 is supported on the main shaft 3 and is positioned circumferentially by keys 4 . The main shaft 3 is supported by bearings 13 mounted on the end covers 12 , 13 and / or the intermediate partition 14 . The rotor 2 has a contact portion 60 whose radius of gyration is approximately the same as that of the inner cavity of the cylinder body 1 , a slidable gap is formed between the contact portion and the inner wall of the cylinder body, and an axially extending sealing band is formed therebetween.

[0019] A chamber dividing device 40 is provided in the cylinder body 1 to divide the sealed chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com