Battery module structure design method based on energy flow analysis

A battery module and structure design technology, applied in the field of battery module structure design based on energy flow analysis, can solve problems such as explosion, car combustion, and high hazards, reduce contact area, increase heat flow path, and reduce possible sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

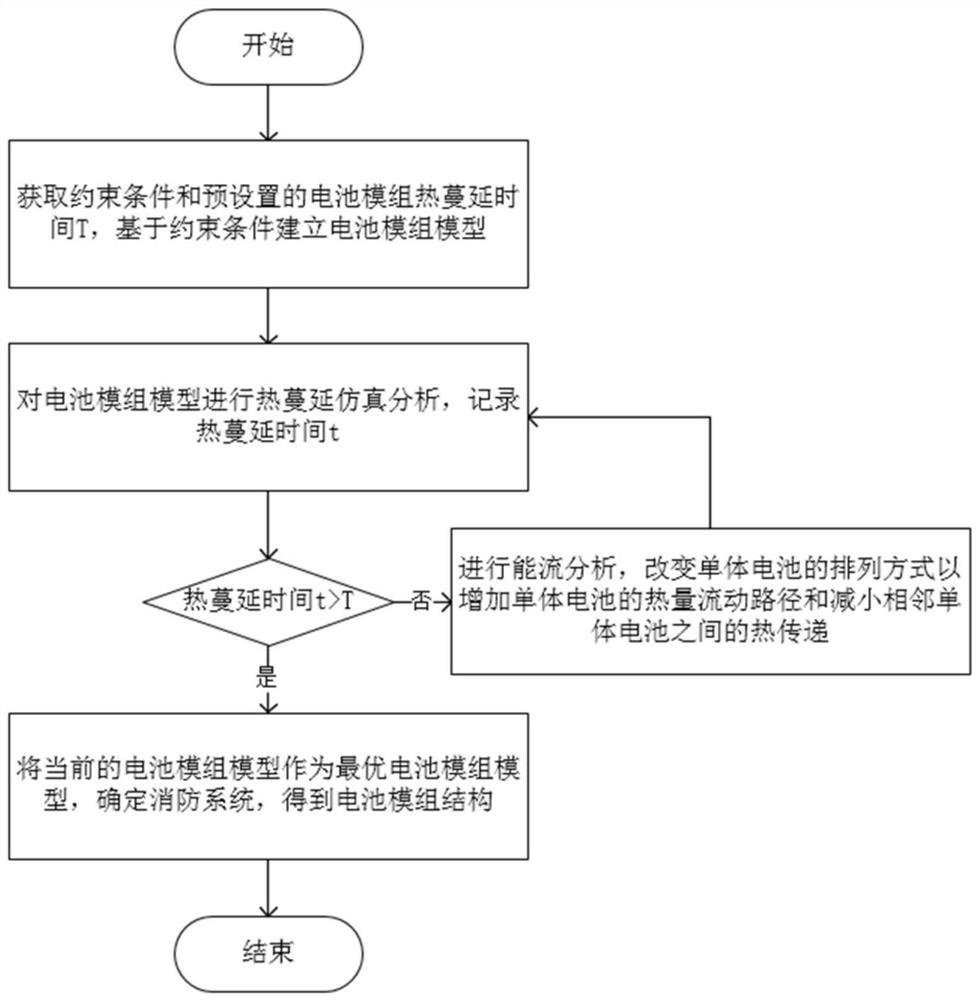

Method used

Image

Examples

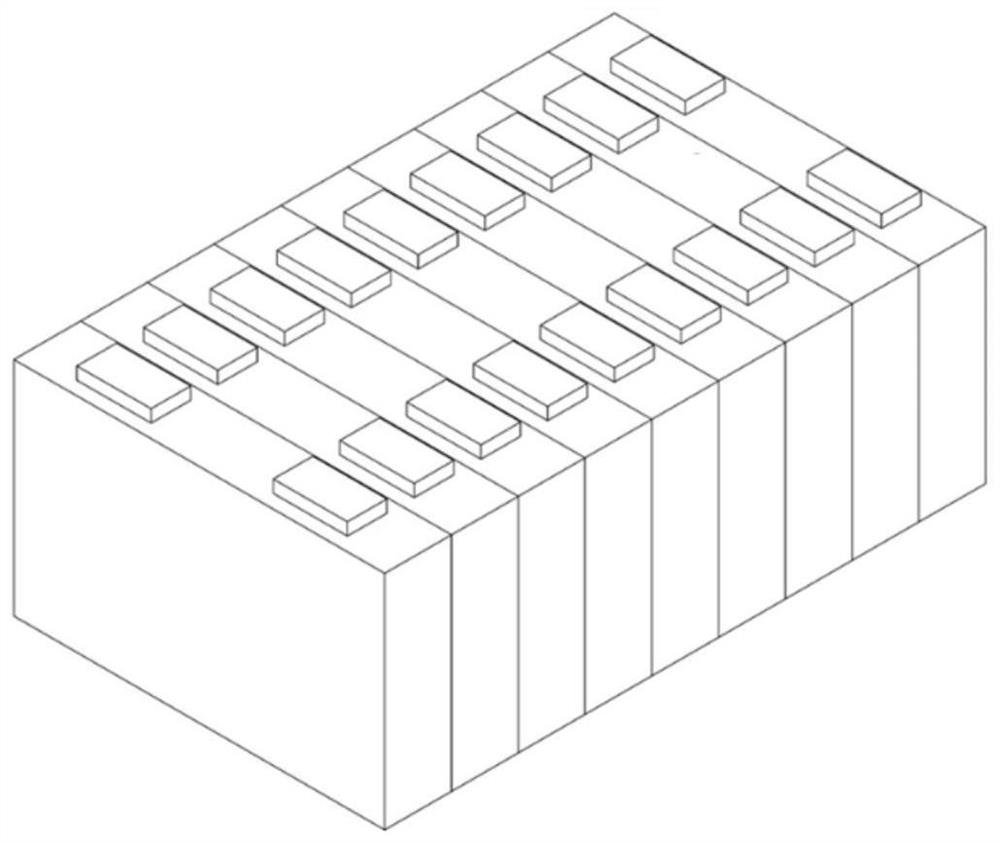

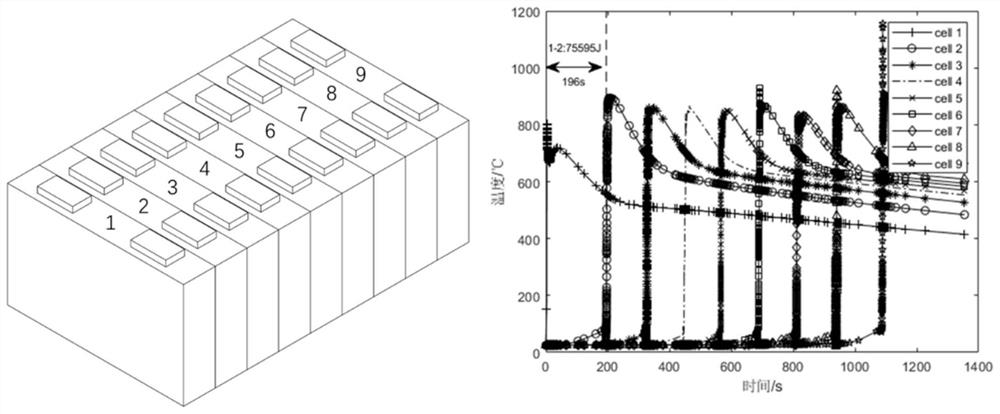

Embodiment 1

[0032] At present, the "Safety Requirements for Traction Batteries for Electric Vehicles" stipulates that the battery pack or system should provide a thermal event alarm signal 5 minutes before the thermal spread caused by the thermal runaway of a single battery, which will cause danger to the passenger compartment (serving for the thermal event of the whole vehicle) alarm to remind occupants to evacuate). This requirement is considered to be fulfilled if heat dissipation does not create a situation that would endanger the vehicle occupants. In the prior art, considering cost and volume constraints, battery modules are arranged in series, such as figure 2 As shown, the heat flow path is single. When a single battery thermal runaway occurs, the heat released by the thermally runaway single battery can only spread one-to-one, and flow to the adjacent single battery, resulting in adjacent The single battery absorbs more heat and heats up faster, so the time for its thermal runa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com