Seabed high-voltage power converter module redundancy switching method and system

A technology of power converter and high-voltage power supply, which is applied in the field of submarine high-voltage power converter module redundancy switching method and system, can solve the problems of high system volume and cost, save cost and space, reduce peak discharge current, reliable discharge and The effect of cutting bypass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

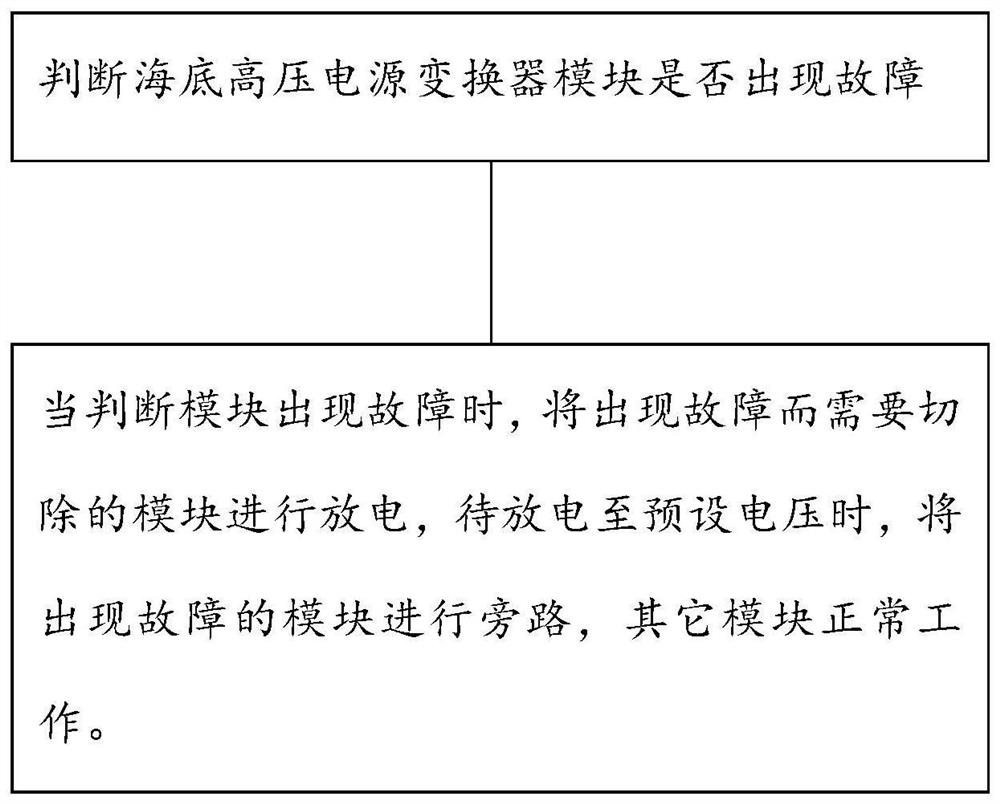

[0033] Such as figure 1 As shown, the redundancy switching method of the submarine high-voltage power converter module in this embodiment belongs to the non-stop switching method, and the specific steps are:

[0034] Judging whether the subsea high-voltage power converter module (such as DC-DC conversion module) is faulty;

[0035] When it is judged that a module is faulty, discharge the faulty module that needs to be removed. When the discharge reaches the preset voltage, the faulty module will be bypassed and removed. Other modules will work normally without stopping to ensure the power converter. Continuous output without shutdown under module failure.

[0036] The redundant switching method of the subsea high-voltage power converter module of the present invention does not need to back up the entire power converter, and only needs to perform redundant operations through each module, which greatly saves cost and space; at the same time, the above redundant switching method...

Embodiment 2

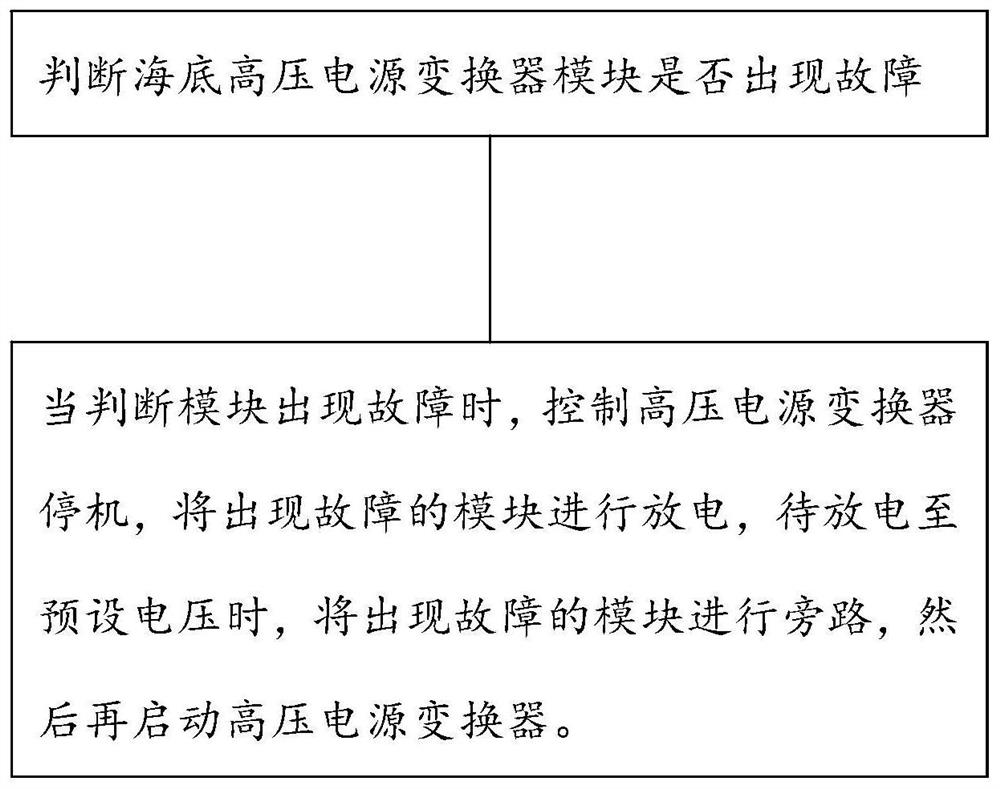

[0057] Such as figure 2 As shown, the redundancy switching method of the submarine high-voltage power converter module in this embodiment belongs to the shutdown switching method, and is applied to a specific scenario where the power supply requirement is not too high. The specific steps are:

[0058] Determine whether the subsea high-voltage power converter module is faulty;

[0059] When it is judged that a module is faulty, the high-voltage power converter is controlled to stop, and the faulty module is discharged. When the discharge reaches the preset voltage, the faulty module is bypassed, and then the high-voltage power converter is started.

[0060] Other contents not described are the same as those in Embodiment 1, and will not be repeated here.

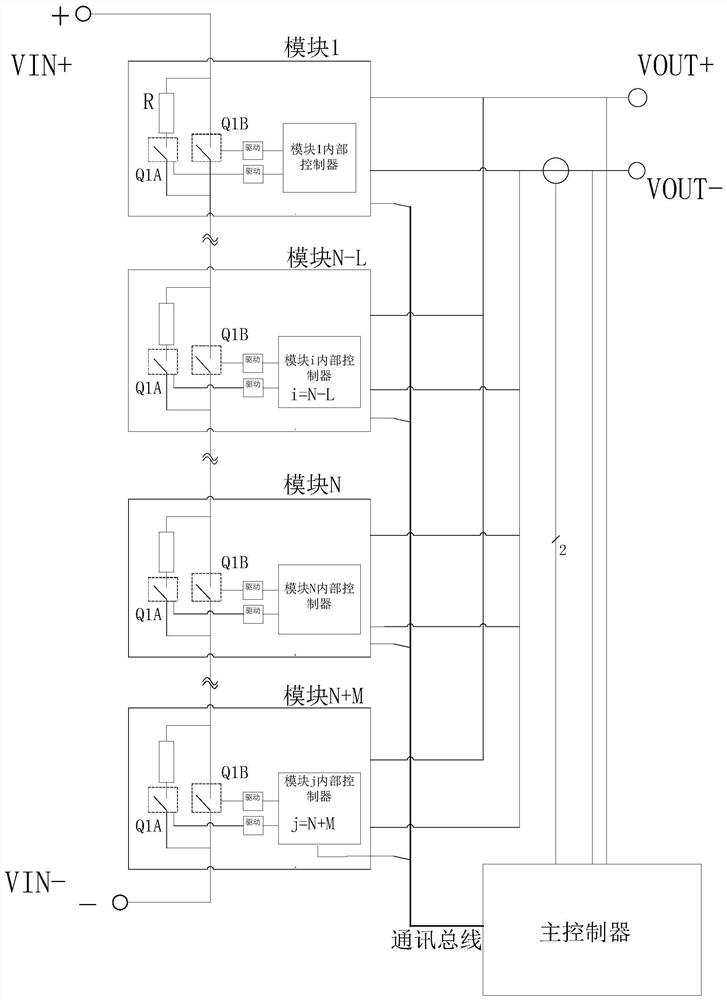

[0061] The present invention correspondingly discloses a redundant switching system of a submarine high-voltage power converter module, including

[0062] The second detection module is used to determine whether the subsea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com