Silt and sewage separation device

A separation device and sewage technology, applied in the direction of filtration separation, separation method, fixed filter element filter, etc., can solve the problems affecting the separation efficiency and achieve the effect of reducing throwing out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

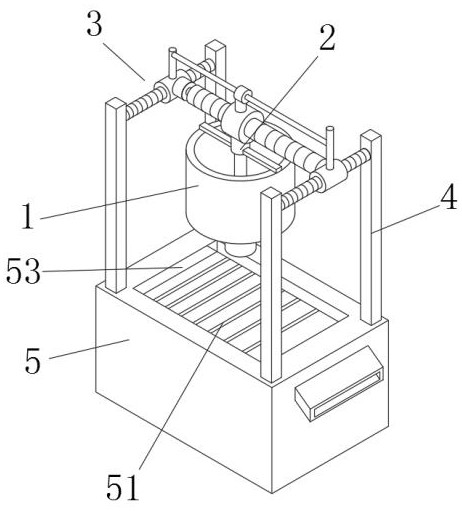

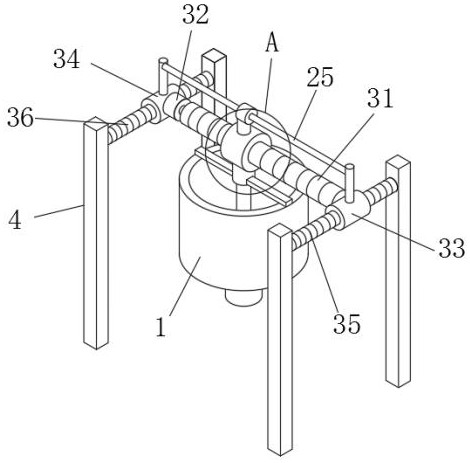

[0035] Refer to attached Figure 1-7 , a sediment sewage separation device, including a separation cylinder 1, a fine crushing structure is provided in the separation cylinder 1, a support assembly 2 is provided on the top of the separation cylinder 1, and the support structure 2 is matched and connected with a driving structure 3, The supporting structure 2 realizes the non-linear motion track of the supporting structure 2 under the action of the driving structure 3 .

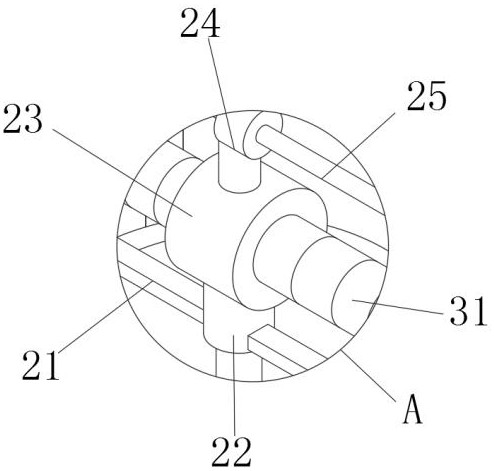

[0036] The support assembly 2 includes a first support plate 21, the two ends of the first support plate 21 are fixedly connected to the top of the separation cylinder 1, and the middle part of the first support plate 21 is provided with a first support rod 22. The top of a support rod 22 is fixedly connected to the support sleeve 23, the support sleeve 23 is matched and connected to the driving structure 3, the top of the support sleeve 23 is provided with a limit sleeve 24, and the limit sleeve 24 is slidabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com